Capacitance type touch control screen and manufacturing method thereof

A technology of capacitive touch and processing method, which is applied in the direction of electric digital data processing, instrument, data processing input/output process, etc., can solve the problems of processing inconvenience, and achieve convenient processing, improved brightness and contrast, and low consumables Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

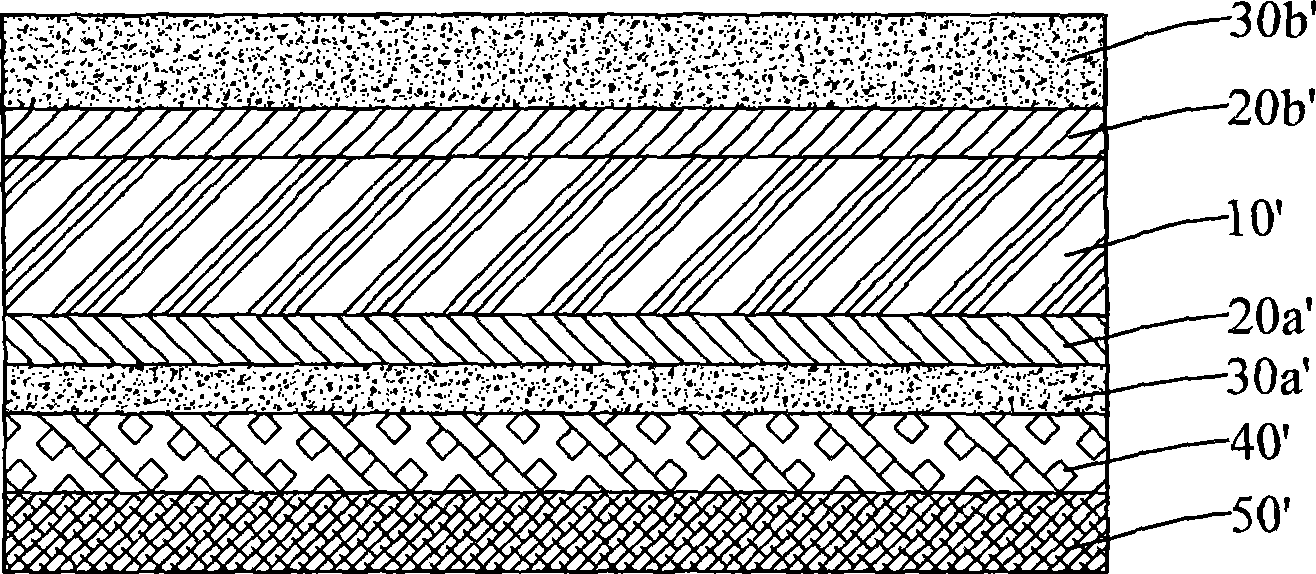

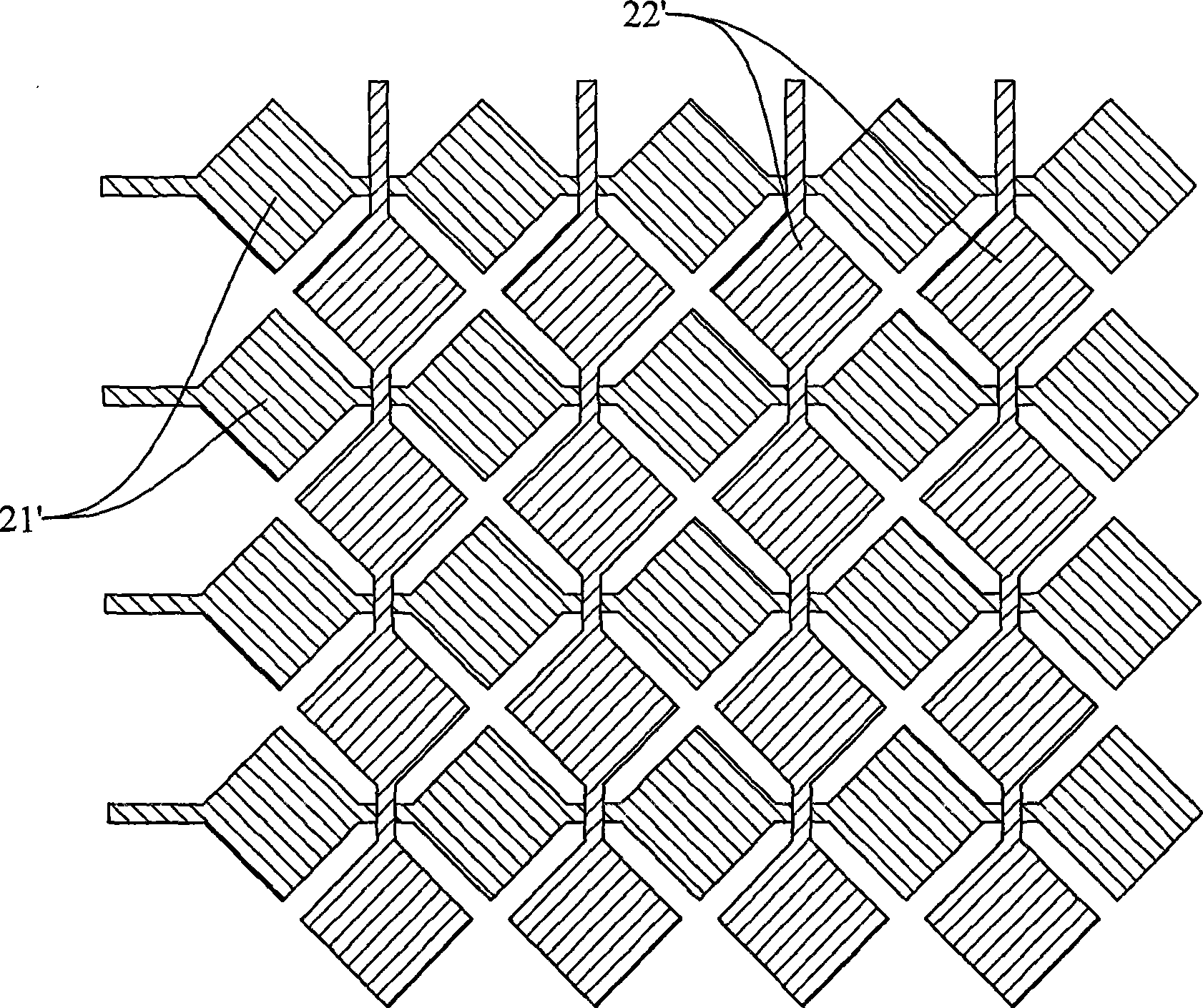

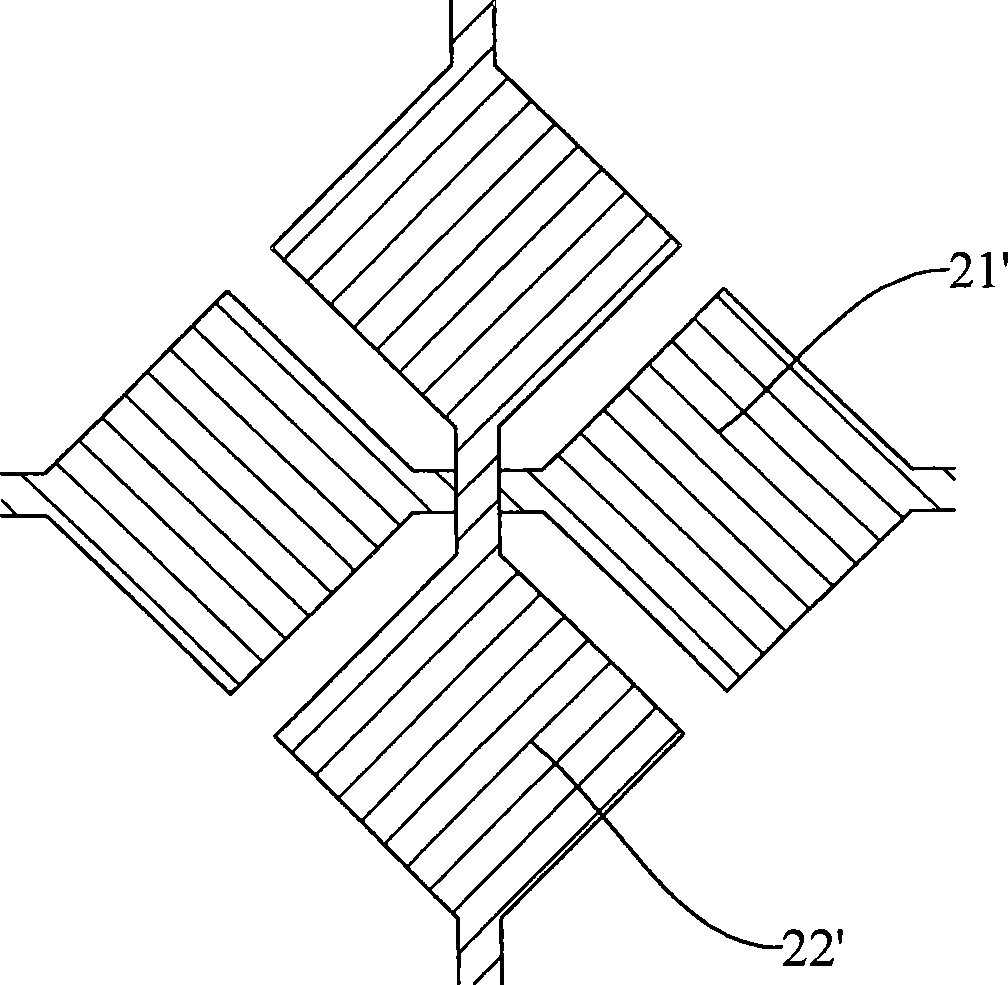

[0057] Such as Figure 4 As shown, in the first embodiment of the capacitive touch screen of the present invention, it includes a substrate 10 , an ITO (Indium Tin Oxide, indium tin oxide) layer 20 , an insulating layer 30 , a circuit layer 40 and a protective layer 50 . Among them, the substrate 10 is mostly made of tempered glass, etc., the ITO layer 20 is formed by a plurality of first axis traces 21 and second axis traces 22 , the insulating layer 30 is disposed on the ITO layer 20 , and the circuit layer 40 is disposed on the insulating layer 30 . Such as Figure 5 As shown, a plurality of first axis traces 21 are arranged parallel to each other, a plurality of second axis traces 22 are arranged parallel to each other, and the first axis traces 21 and the second axis traces 22 intersect to form the ITO layer 20 . Such as Image 6 , 7 As shown, at the intersection, the first axis trace 21 is divided into a plurality of units P by the second axis trace 22, and two adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com