Operation control method of wind power generation

A wind power generation system and operation control technology, applied in the control of wind power generators, wind power generation, engine control, etc., can solve the problems of grid power facilities and electrical appliances, wind power cannot be connected to the grid on a large scale, waste of wind power generation capacity, etc. Achieve the effect of increasing the maximum annual power generation, increasing the annual power generation, and increasing the power generation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

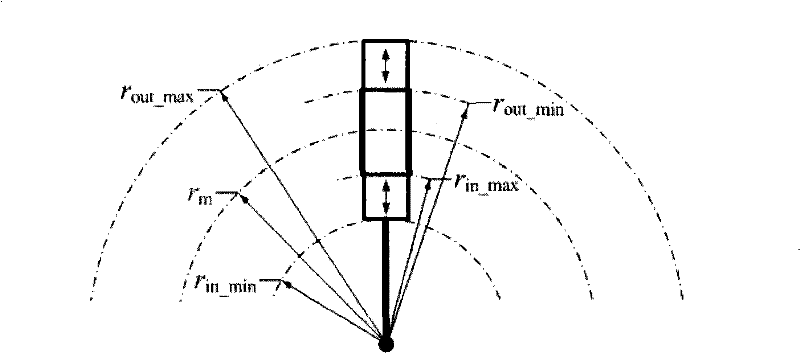

[0019] The basic idea of the present invention is that the wind power generating set adopts the retractable blade structure, and the rated wind speed and rated power setting value of the fan are correspondingly reduced; the retractable blade structure is combined with the variable pitch system to adjust the output power.

[0020] The following will be described in detail in conjunction with the accompanying drawings and embodiments.

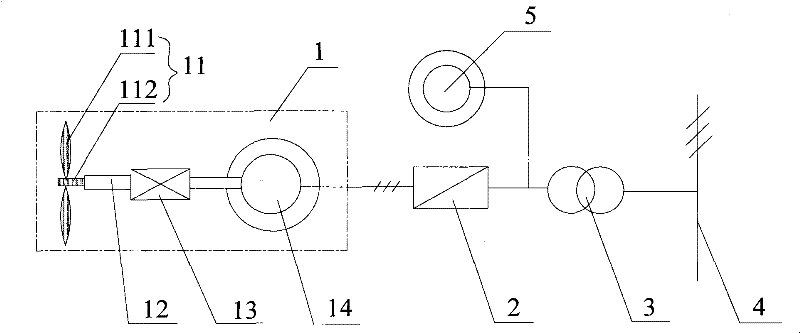

[0021] Please refer to figure 1 , which is a block diagram of a preferred embodiment of the wind power generation unit and the wind power generation system of the present invention. The wind power generating set 1 described in the present invention comprises:

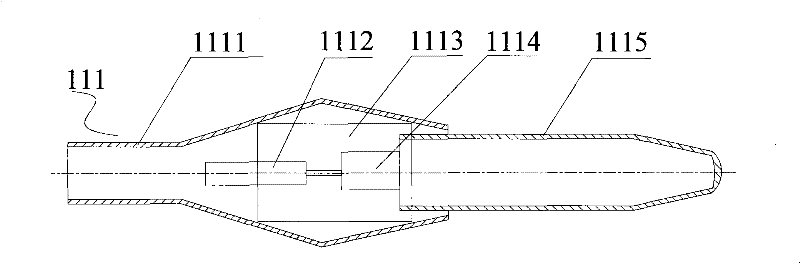

[0022] The wind wheel 11 is used to convert wind energy into mechanical energy; the wind wheel 11 includes a blade 111 and a hub 112, the blade root of the blade 111 is fixed on the hub 112, the hub 112 is connected to one end of the main shaft 12, and the other end of the main shaft 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com