Horizontally adjusting keel and adjusting screw thereof

A technology of level adjustment and nut adjustment, which is applied to the direction of screws, threaded fasteners, floors, etc., can solve problems such as the inability to solve the moisture absorption deformation of the keel, the difficulty of installing wedges in place at one time, and the inability to solve the problem of floor warping, etc., to eliminate The effect of stepping on the hidden danger, convenient level adjustment, and convenient production and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

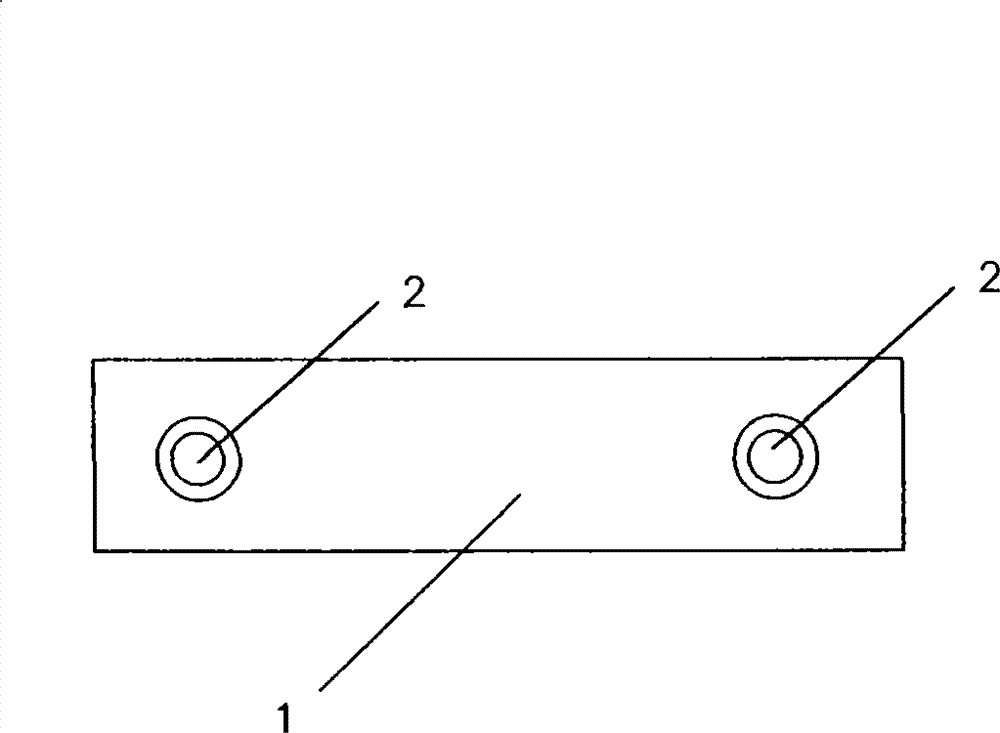

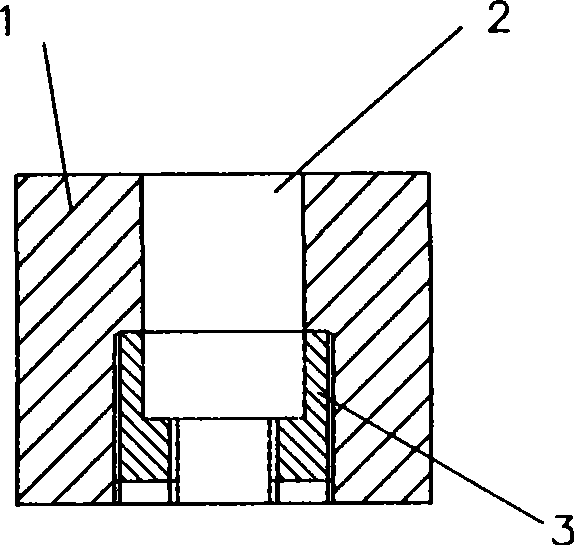

[0029] Such as figure 1 , figure 2 As shown, the keel suitable for horizontal adjustment described in this embodiment includes a keel body 1, which is a cuboid with a length of 500mm, and a "convex"-shaped height adjustment hole 2 is provided at each end.

Embodiment 2

[0031] Such as figure 1As shown, the keel suitable for horizontal adjustment described in this embodiment includes a keel body 1, the keel body 1 is a cuboid with a length of 500mm, and a "convex"-shaped height adjustment hole 2 is provided at each end, such as figure 2 As shown, an adjustment nut 3 is arranged in the height adjustment hole 2 .

Embodiment 3

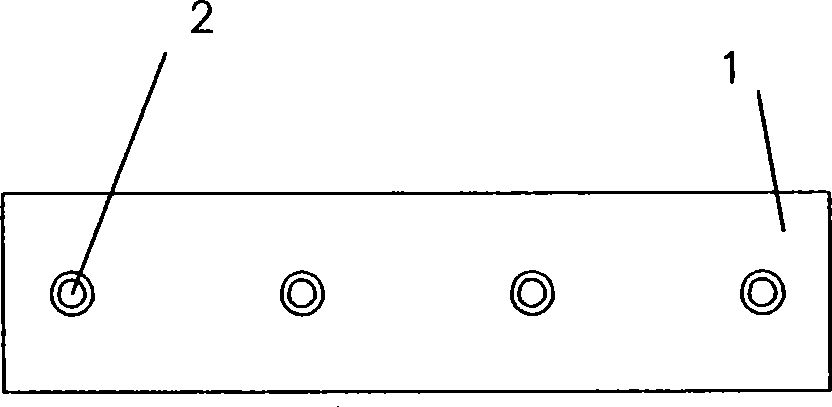

[0033] Such as image 3 As shown, the keel suitable for horizontal adjustment described in this embodiment includes a keel body 1. The keel body 1 is a cuboid with a length of 1200mm. It is provided with four "convex"-shaped height adjustment holes 2, and the hole spacing is about is 350mm. Such as figure 2 As shown, an adjustment nut 3 is provided in the height adjustment hole 2, such as Figure 5 , Figure 6 As shown, the rear end surface of the adjustment nut 3 is provided with a second card slot 15 for using a rotary tool, the coaxial inner hole 12 is provided with an adjustment thread 14, and the coaxial inner hole is provided with a step 13, and forms a space that can accommodate fastening Nut cavity 19, such as Figure 6 , Figure 15 As shown, the second anti-loosening locking pattern 23 is provided on the step, and the upper end of the inner wall of the cavity 19 of the adjustment nut is formed with multi-point tiny protrusions 24 along the mouth, such as Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com