Phthalimide diglycidyl ether and preparation thereof

A technology of phthalimide and diglycidyl ether, which is applied in the field of high-performance resin and its preparation, can solve the problems of high curing and molding temperature, high softening point and high price of high-performance resin, so as to improve reliability, Abundant sources and simple crafting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

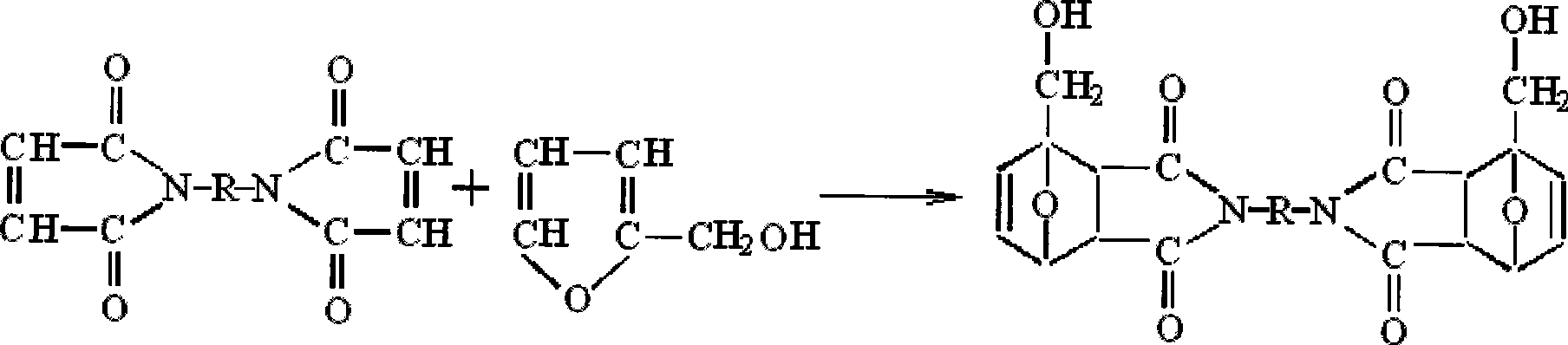

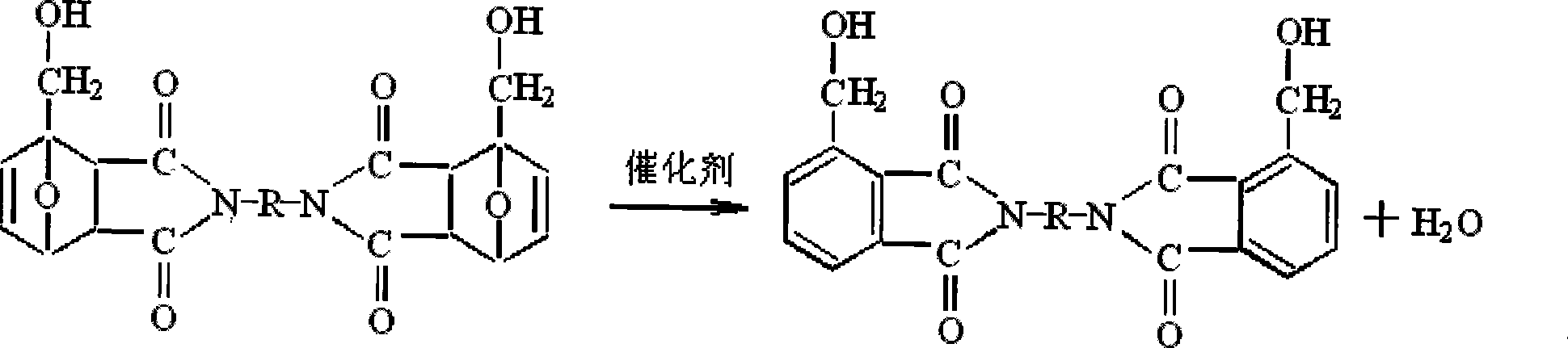

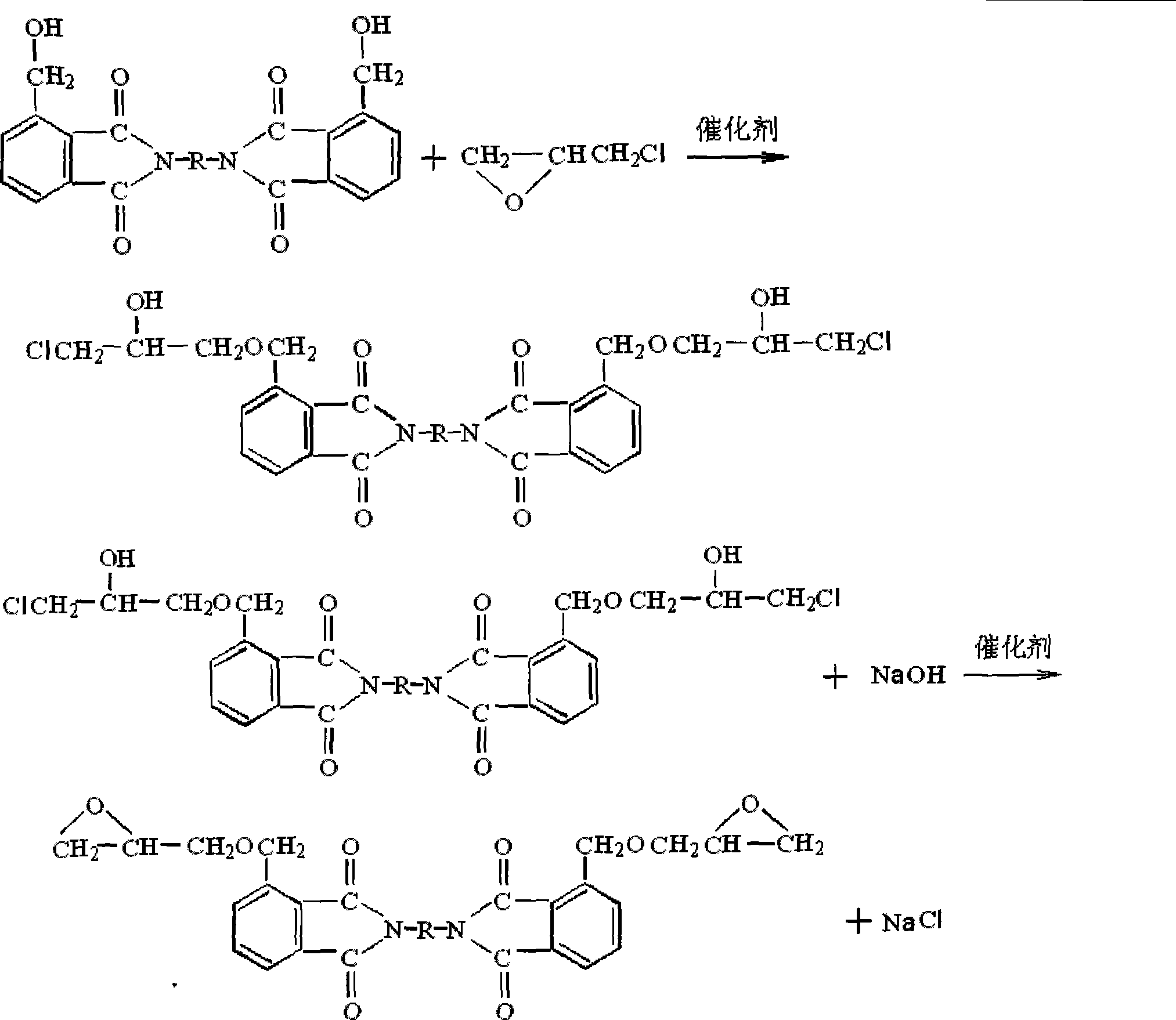

[0015] Specific embodiment one: In this embodiment, phthalimide diglycidyl ether consists of 100 parts by weight of diphenylmethane bismaleimide, 160-170 parts of furfuryl alcohol, and 350-370 parts of epoxy Chloropropane and 20-25 parts of sodium hydroxide are prepared through addition reaction, phthalylation reaction and epoxidation reaction.

specific Embodiment approach 2

[0016] Specific embodiment two: In this embodiment, phthalimide diglycidyl ether consists of 100 parts by weight of diphenylmethane bismaleimide, 162 to 165 parts of furfuryl alcohol, and 350 to 365 parts of epoxy Chloropropane and 21 to 24 parts of sodium hydroxide are prepared through addition reaction, phthalylation reaction and epoxidation reaction.

specific Embodiment approach 3

[0017] Specific embodiment three: In this embodiment, phthalimide diglycidyl ether is made up of 100 parts of diphenylmethane bismaleimide, 164 parts of furfuryl alcohol, 360 parts of epichlorohydrin and 22.5 parts by weight. Parts of sodium hydroxide are prepared through addition reaction, phthalylation reaction and epoxidation reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com