Catalyst for biological treatment of formaldehyde industrial wastewater

A technology for industrial wastewater and biological treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of low domestication rate of activated sludge, long biochemical debugging process, and microbial growth. Incomplete and other problems, to achieve the effect of accelerating the growth of catalytic bacteria, shortening the time of domestication and culture, and accelerating the growth and reproduction of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

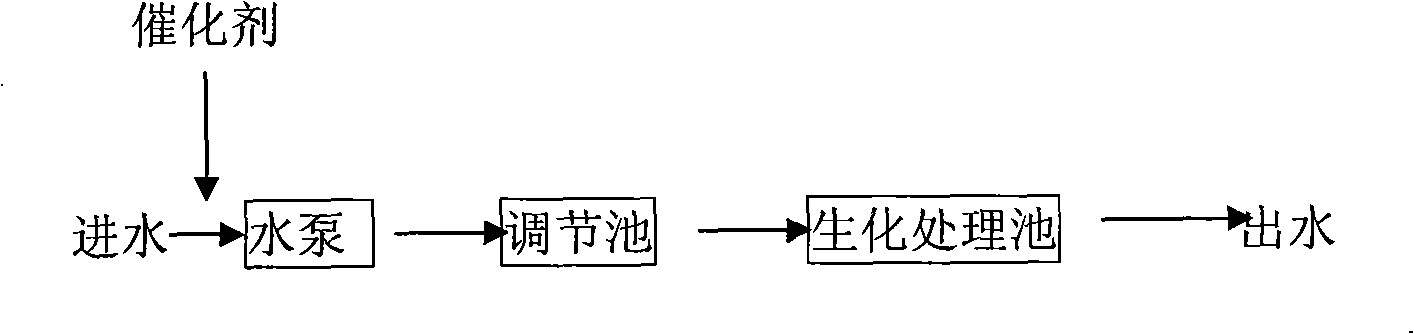

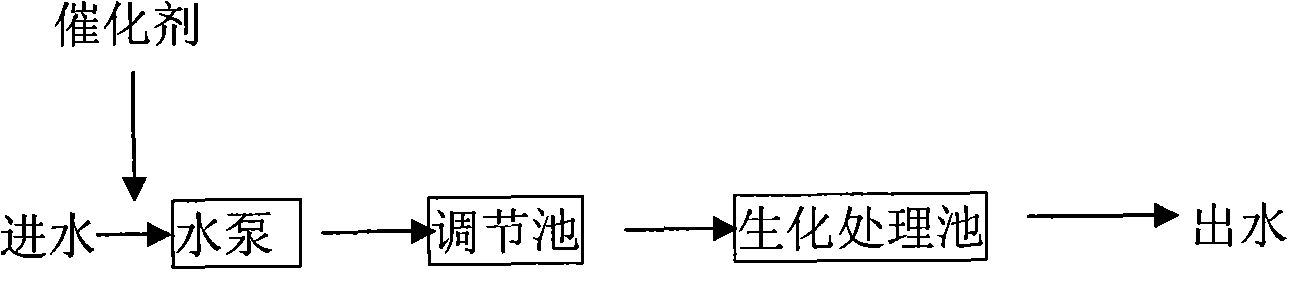

Method used

Image

Examples

Embodiment 1

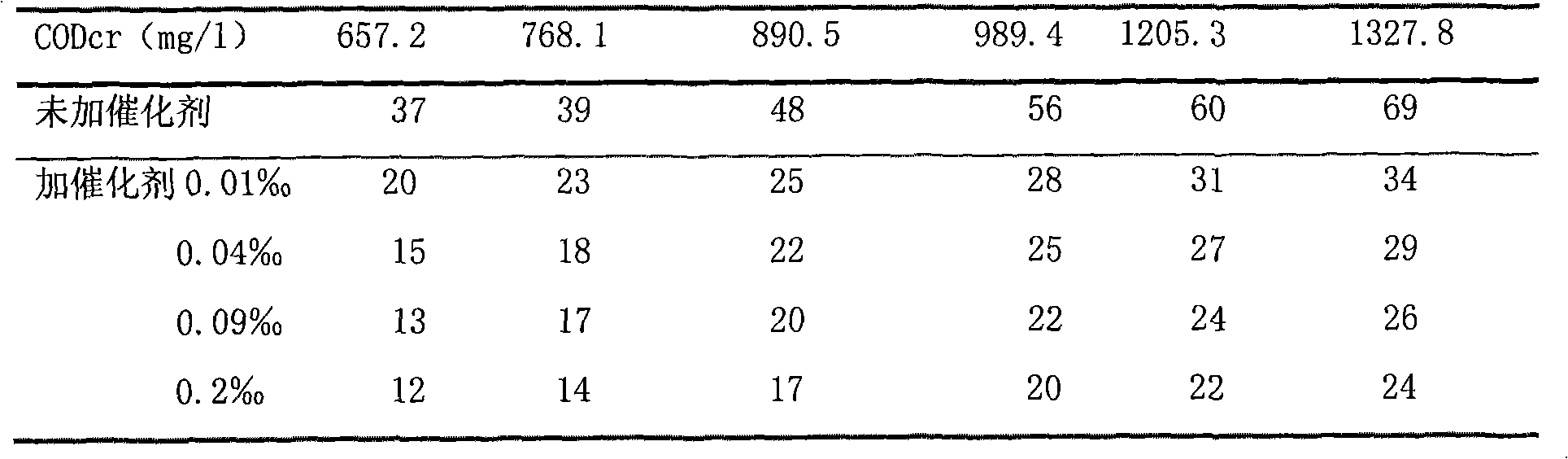

[0021] (1) Experimental results of microaerobic biological treatment of formaldehyde wastewater

[0022] Take formaldehyde industrial wastewater with different CODcr, and add different amounts of biological treatment catalysts (0.01‰~0.2‰) for comparative experiments. Table 1 shows the acclimatization time (day) of microaerobic biochemical treatment of formaldehyde industrial wastewater with different CODcr under different catalyst conditions, and the formaldehyde removal rate is shown in Table 2.

[0023] Table 1 microaerobic biochemical treatment bacterial culture acclimatization time (day)

[0024]

[0025] It can be seen from Table 1 that the domestication time of microaerobic bacteria in different CODcr formaldehyde industrial wastewater is different under the condition of different amount of biocatalyst, and the stronger the inhibitory effect of microorganisms under the condition of no catalyst, the longer the domestication time is. After adding the biological treatm...

Embodiment 2

[0030] (2) Aerobic treatment experiment of formaldehyde industrial wastewater

[0031] Formaldehyde industrial wastewater with different CODcr concentration was taken, and different biocatalysts were added for aerobic biological treatment. The biochemical treatment effect of formaldehyde industrial wastewater with different CODcr concentration was significantly different under the condition of different biochemical catalyst amounts. Wherein different CODcr concentration under the situation of different catalyst amount aerobic biochemical aerobic bacteria culture acclimatization time (day) is different, the result is shown in Table 3. The CODcr removal efficiency (%) of aerobic biochemical treatment is shown in Table 4.

[0032] Table 3 Different CODcr concentration of formaldehyde industrial wastewater aerobic biochemical treatment bacterial culture acclimation time (day)

[0033]

[0034] It can be seen from Table 3 that in the process of aerobic biochemical treatment of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com