Drive system for hybrid power automobile air conditioner compressor and hydraulic pump

A technology for hybrid electric vehicles and air-conditioning compressors, which is applied to the arrangement of multiple prime movers of power plants and general power plants, and air pressure power plants. Energy-saving goals and other issues to achieve the effect of eliminating mechanical loads and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

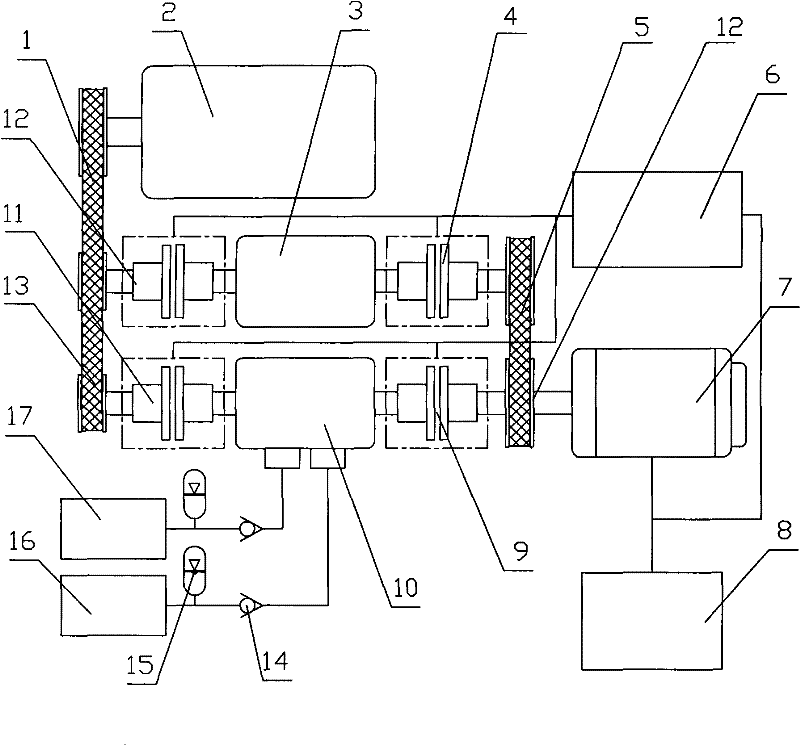

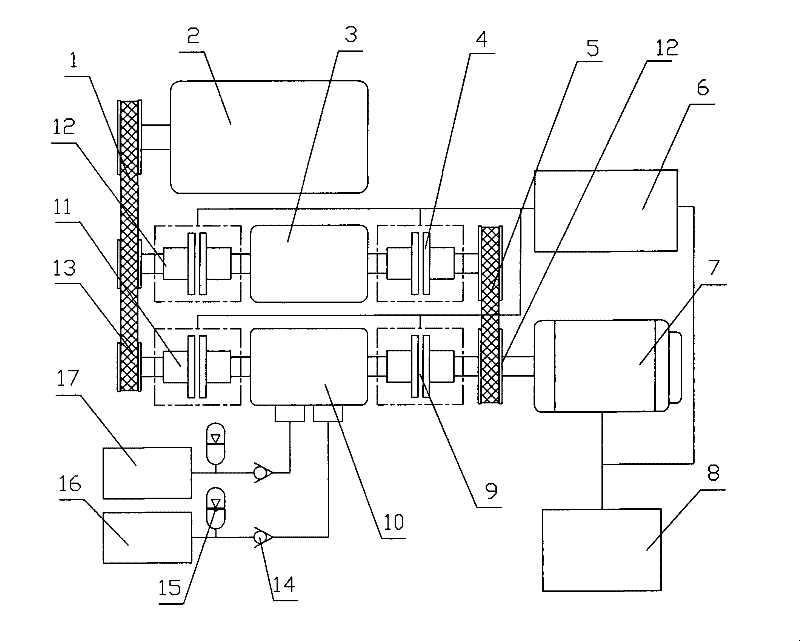

[0019] Accompanying drawing is a structural representation of the present invention, as shown in the figure: the hybrid vehicle air-conditioning compressor of the present embodiment and the hydraulic pump drive system comprise engine 2, accumulator 8 and motor 7, and accumulator 8 is the power supply of motor 7; Drive air-conditioning compressor 3 and hydraulic pump 10 by clutch I 12 and clutch II 11 respectively, electric motor 7 drives air-conditioning compressor 3 and hydraulic pump 10 by clutch III4 and clutch IV9 respectively; In the present embodiment, clutch I 12 and clutch III4 and The air-conditioning compressor 3 is coaxially connected, and the clutch II 11 and clutch IV9 are coaxially connected with the hydraulic pump 10, so that the entire drive system is compact in structure, easy to install and maintain, and reduces energy loss during transmission;

[0020] Also includes controller 6, clutch I 12, clutch II 11, clutch III4 and clutch IV9 are electromagnetic clutch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com