Microwave sensing for determination of loading of filters

A filter and microwave technology, used in instruments, measuring devices, measuring electrical variables, etc., can solve the problems of limited fatigue life of filters, large thermal stress, high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

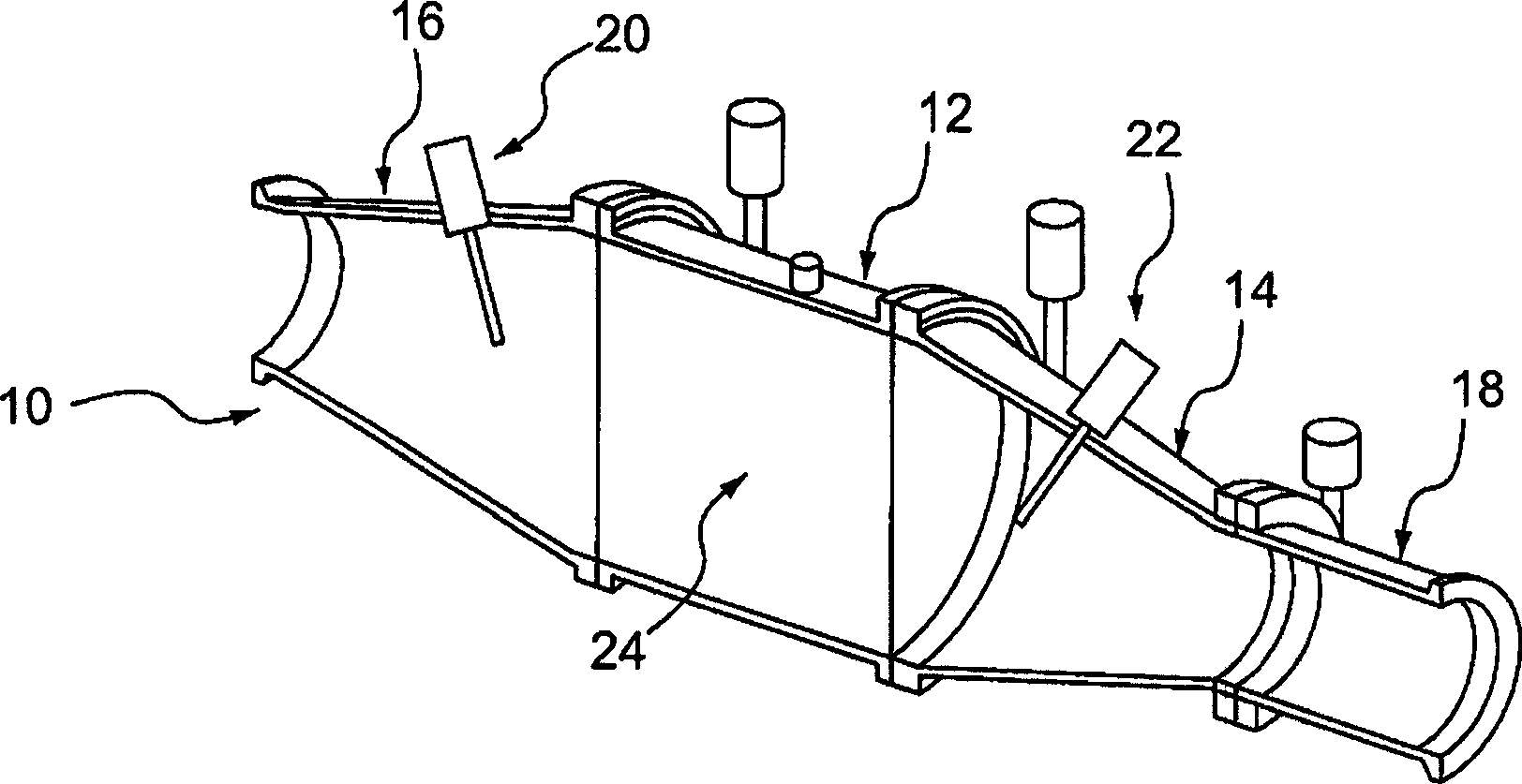

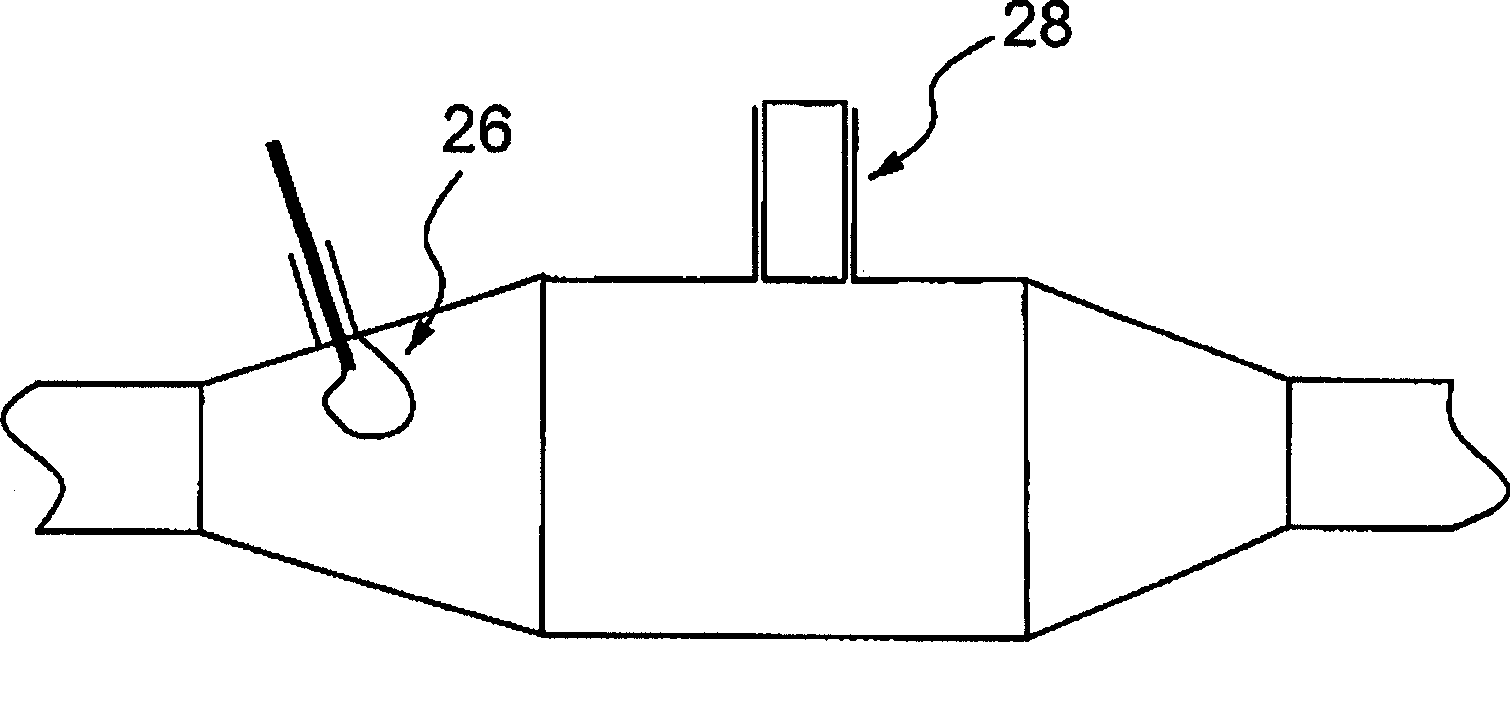

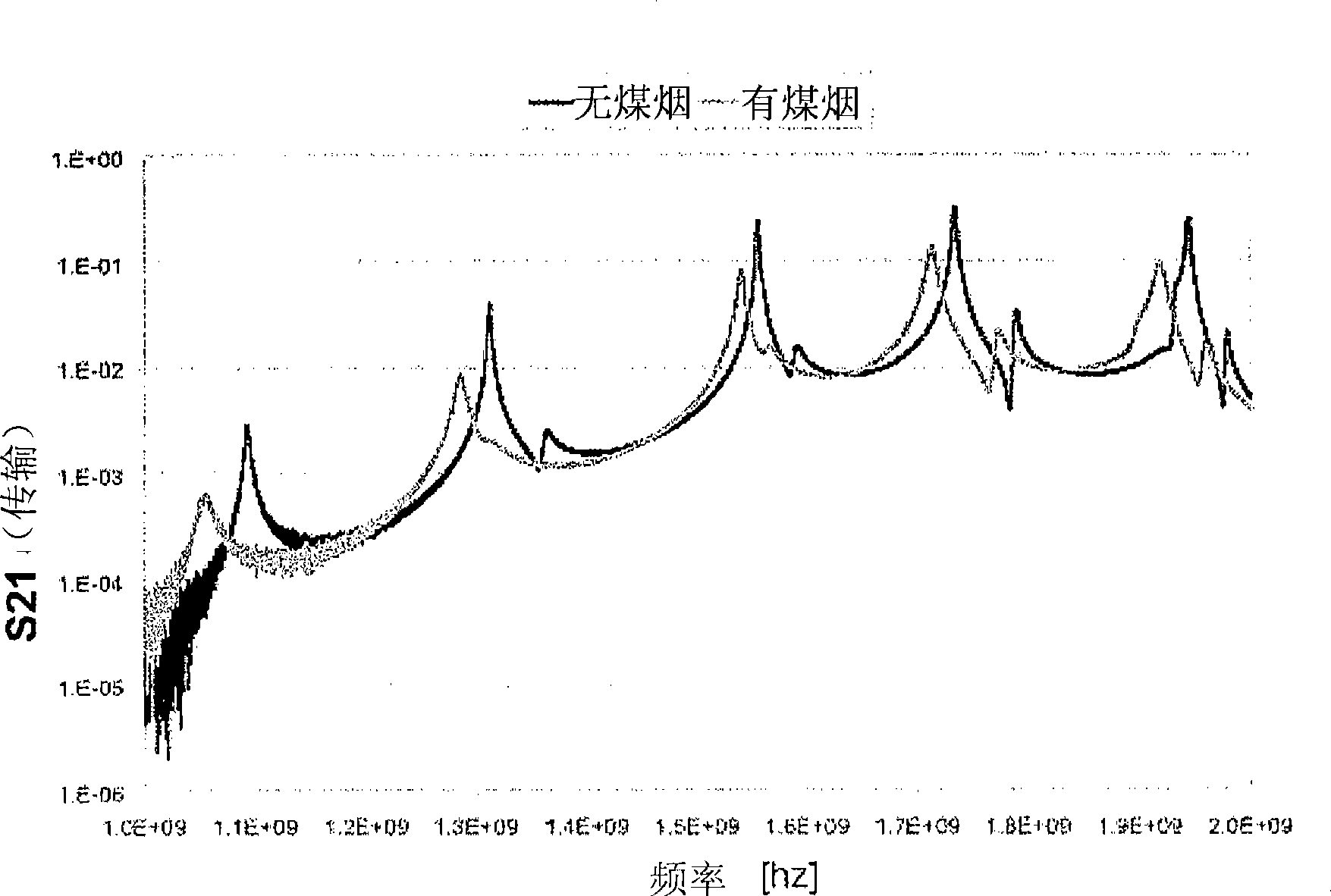

[0018] The invention is based on the insight that microwaves can be used to determine the state of the load of a collector or filter. The load can be soot, particulate, ash or any solid / liquid. In addition to determining the total load, the microwave system that will be described herein can also be used to determine the distribution of the load throughout the collector. Microwave sensing used in the present invention can be relatively inexpensive since inexpensive oscillators and detectors are commercially available in the frequency range of interest.

[0019] In the case of a diesel particulate filter, the particulates consist of soot and other organic compounds (solid and / or liquid) and ash. For the purposes of this invention, the combination of carbon, organic compounds, and ash will be referred to (for simplicity) as soot. Those skilled in the art will recognize that soot and organic compounds are removed by regeneration, but the ash load will still be present.

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com