Hydraulic unit for a cylinder head for a combustion engine with a variable valve stroke

A technology for valve actuators, hydraulic units, applied in the direction of valve devices, engine components, machines/engines, etc., which can solve the problems of air bubble inhalation, not reliably avoiding formation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

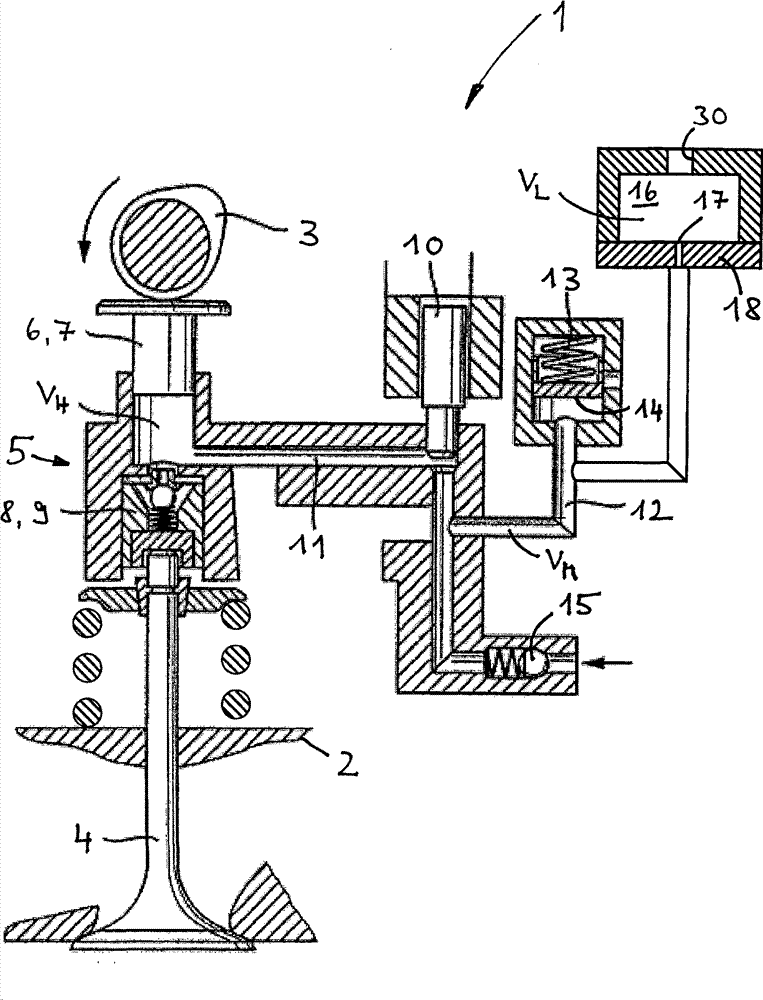

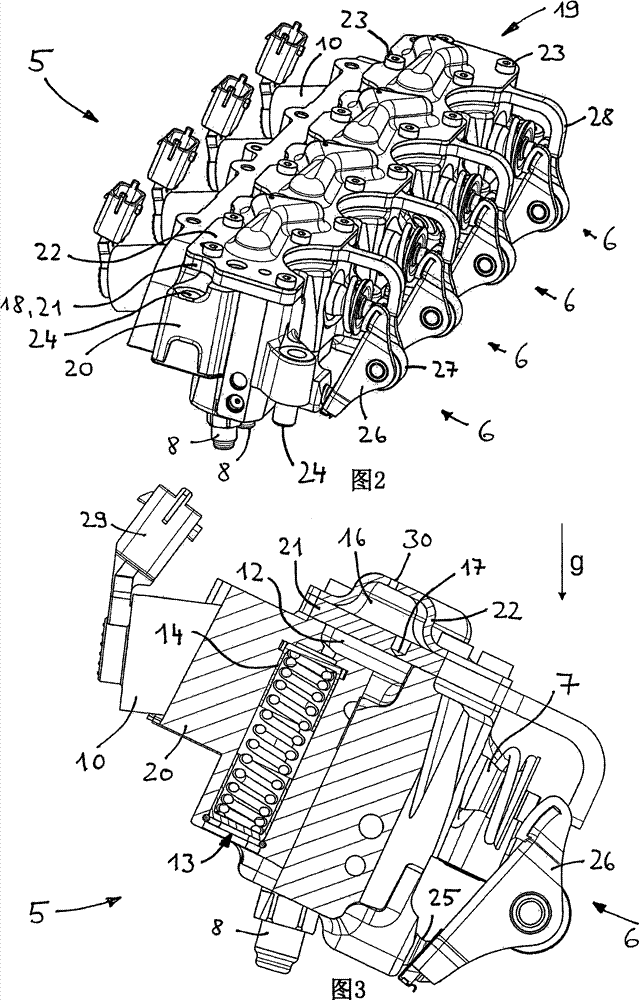

[0026] exist figure 1 The principle structure of the hydraulically variable valve drive 1 and the features pertaining to the invention are disclosed schematically in . To facilitate the understanding of the invention, a main section of a cylinder head 2 of an internal combustion engine is shown, including a cam 3 of a camshaft and a gas exchange valve 4 which is spring-loaded in the closing direction. The variability of the valve actuator 1 is produced by means of a hydraulic unit 5 arranged between the cam 3 and the gas exchange valve 4, the hydraulic unit 5 comprising the following components:

[0027] - a detector unit 6 on the drive side, here in the form of a pump plunger 7 driven by the cam 3;

[0028] - a receiver unit 8 on the driven side, here in the form of a receiver piston 9 directly actuating the gas exchange valve 4;

[0029] - a controllable hydraulic valve 10, here in the form of an electromagnetic 2-position, 2-way distribution valve;

[0030] - a high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com