Self-buckling type slide anti-theft lock with anti-push pressure and pick-proof functions

A self-buckling and sliding technology, applied in the field of anti-theft locks, can solve the problems of further improvement of anti-theft performance, no anti-push function, and hidden dangers of anti-theft locks, so as to improve practicability and applicability, and improve design blind spots. , the effect of eliminating security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

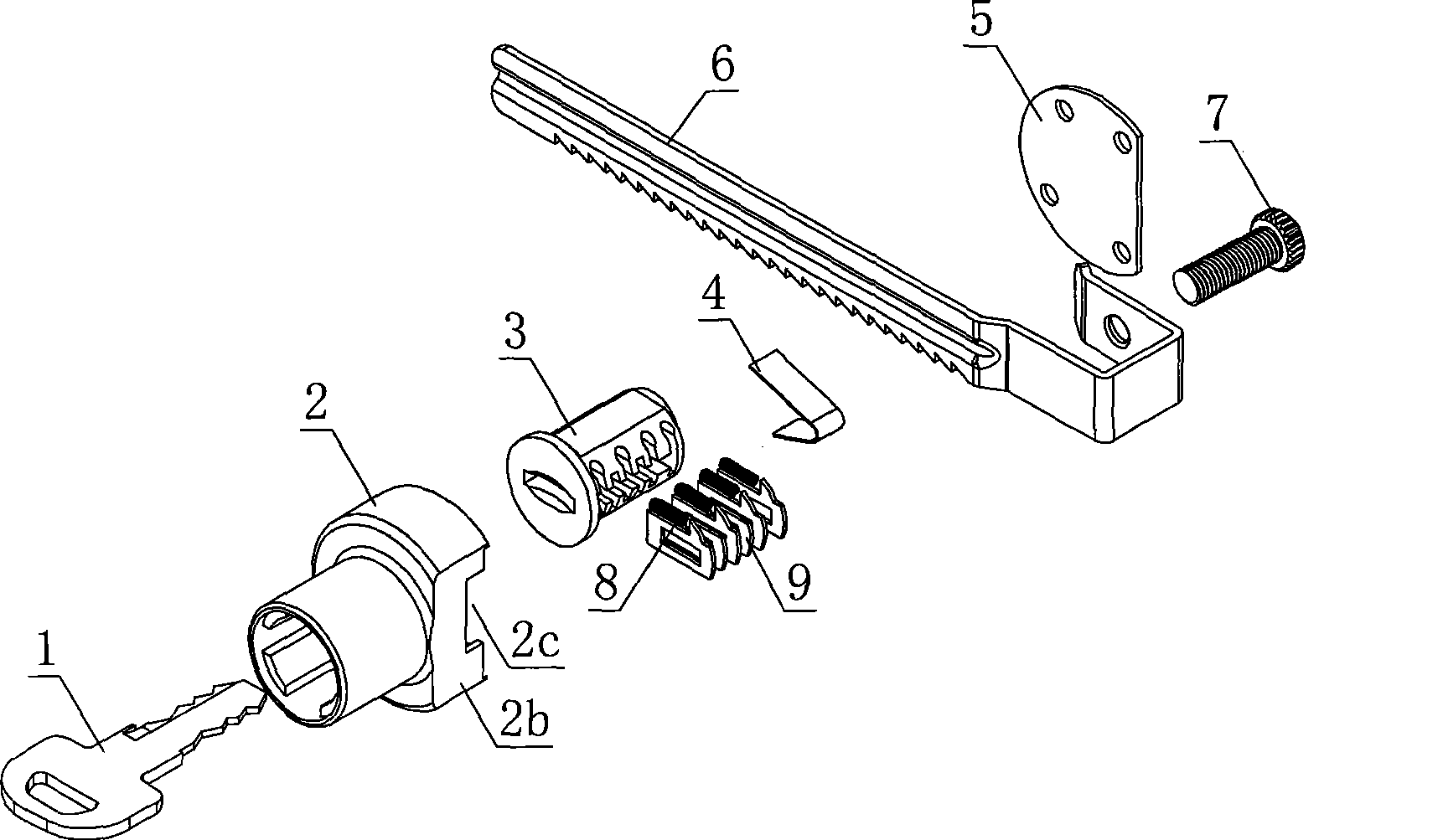

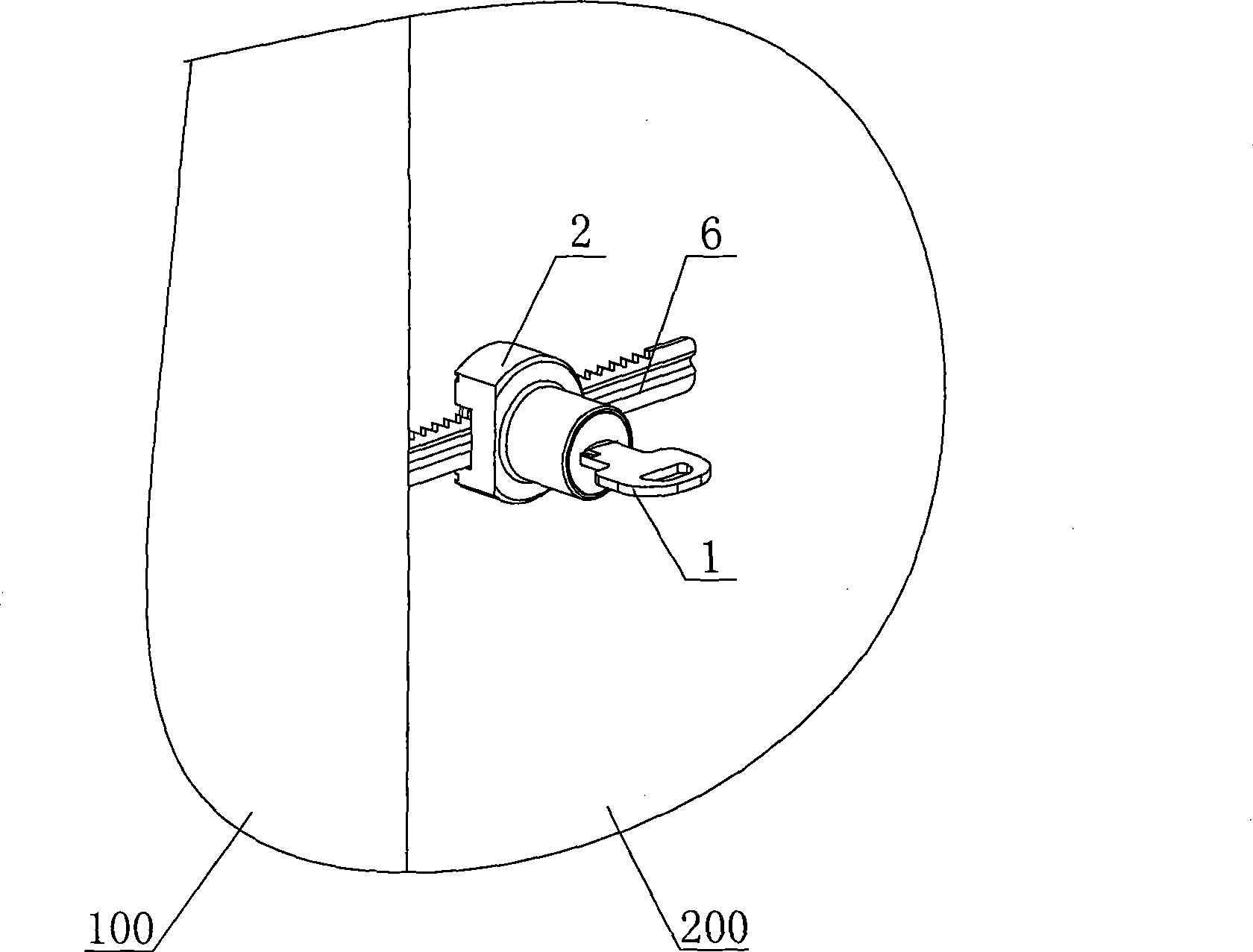

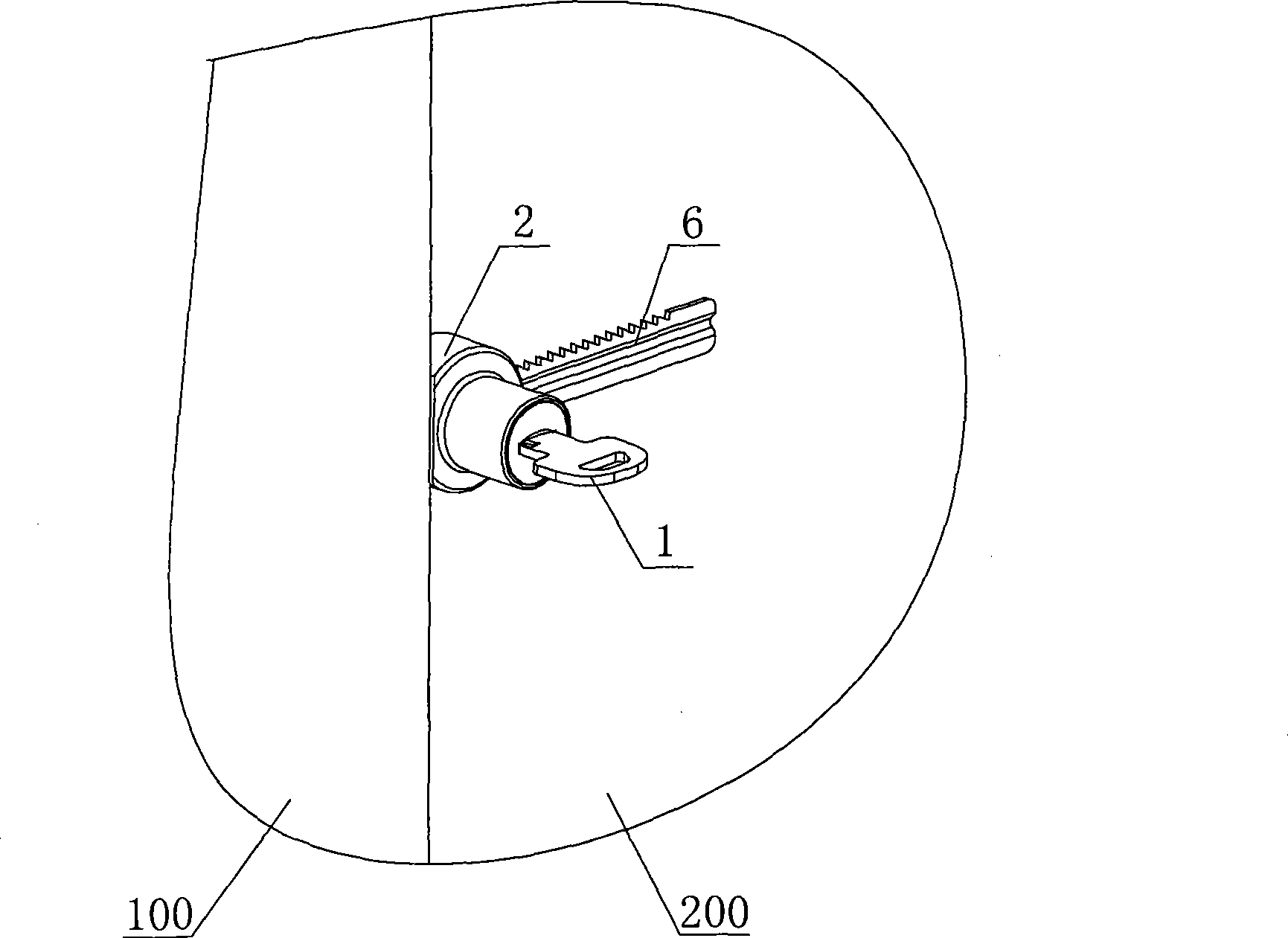

[0035] Figure 4A to Figure 9 A self-buckle sliding type anti-theft lock with the function of anti-push, pressure and pry resistance is shown, including a key 1, a lock case and a lock bolt 6, the lock bolt 6 has a row of ratchet teeth, and the lock case is provided with a lock bolt 6 Through the lock bolt hole 2c, the lock case is composed of the base 5 and the lock sleeve 2 connected by the screw 7, and a cavity is formed between the two, and the lock core 3, the spring 8, the insert piece 9 and the lock bolt shrapnel are installed in the cavity 4. The installation position of the spring 8 and the insert 9 matches the installation position of the lock cylinder 3. The lock cylinder 3 has a keyhole for the key 1 to be inserted into. The piezoresistive prying mechanism is a cover tongue 2a formed by extending outward from the lower part of the lock sleeve 2, and the cover tongue 2a is an arc-shaped sheet structure, which plays the role of covering and pressing the door panel. ...

Embodiment 2

[0038] Such as Figure 10A to Figure 15 As shown, the difference between the present embodiment and the first embodiment is that the lock sleeve 2 is the same as the lock sleeve 2 in the prior art, and its anti-push and pry resistance mechanism is a buckle added to the cross-cut part of the base 5, and the buckle It has a transverse part 5b and a hemming part 5a which is perpendicular to the transverse part 5b and is folded outwards. Both the transverse part 5b and the hemming part 5a are of a sheet structure, wherein the transverse part 5b is a square sheet structure, and the hemming The part 5a is an arc-shaped sheet structure, and the transverse part 5b has an opening 5c which communicates with the lock bolt hole 2c and allows the lock bolt 6 to pass through. The flap 2a has the same effect and is used to cover and press the door panel.

[0039]In this embodiment, the lateral part 5b of the buckle is the contact surface with the sliding door. During installation, the loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com