Steel tube concrete - punching steel plate - concrete combined shear wall and manufacturing method thereof

A technology of steel tube concrete and combined shear walls, which is applied in the direction of walls, building components, and anti-seismic, can solve the problems affecting the anti-seismic capacity and poor ductility of shear wall structures, and achieve stable anti-seismic performance, improved ductility and bearing capacity, and load-bearing The effect of slower force and stiffness decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

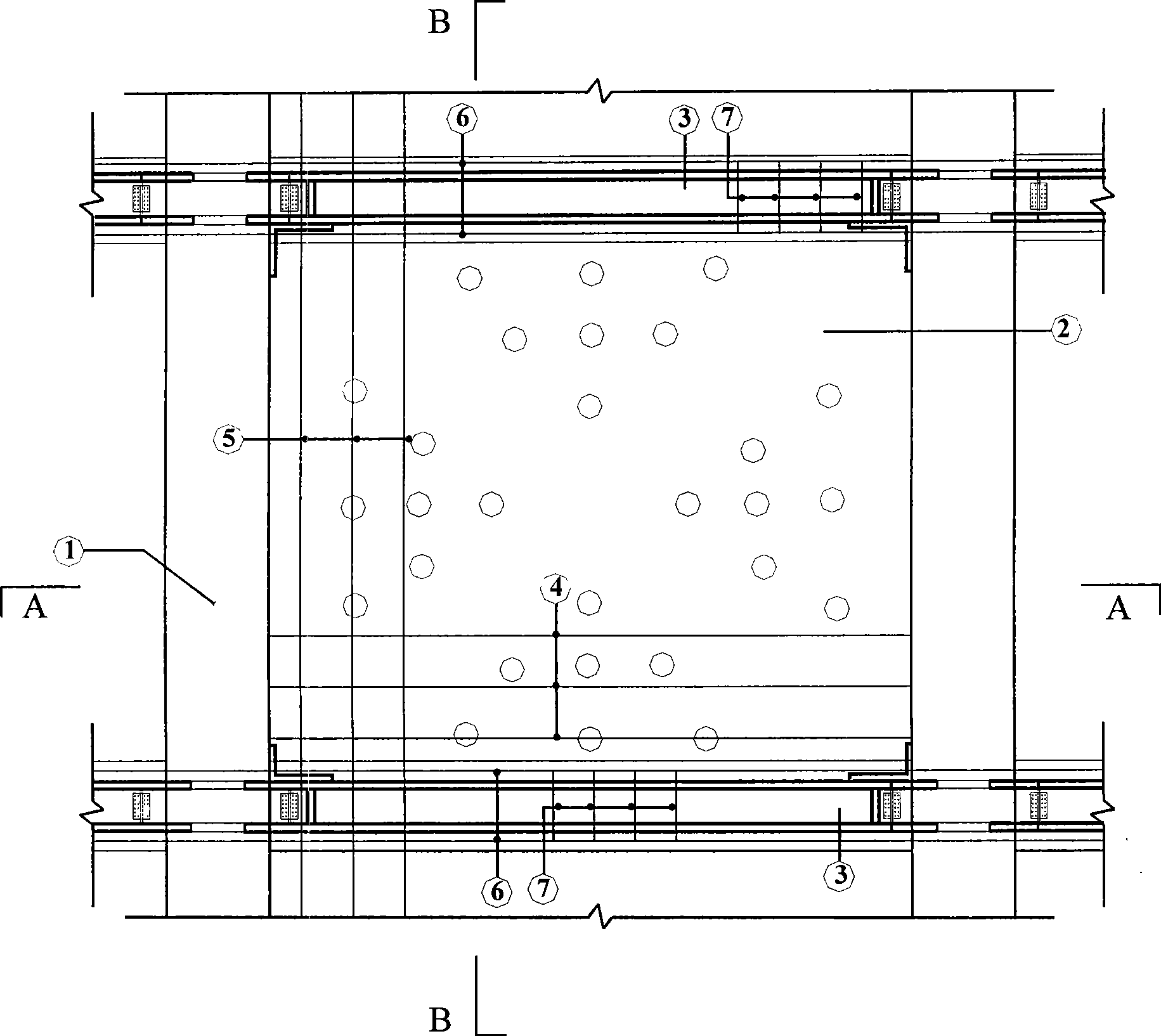

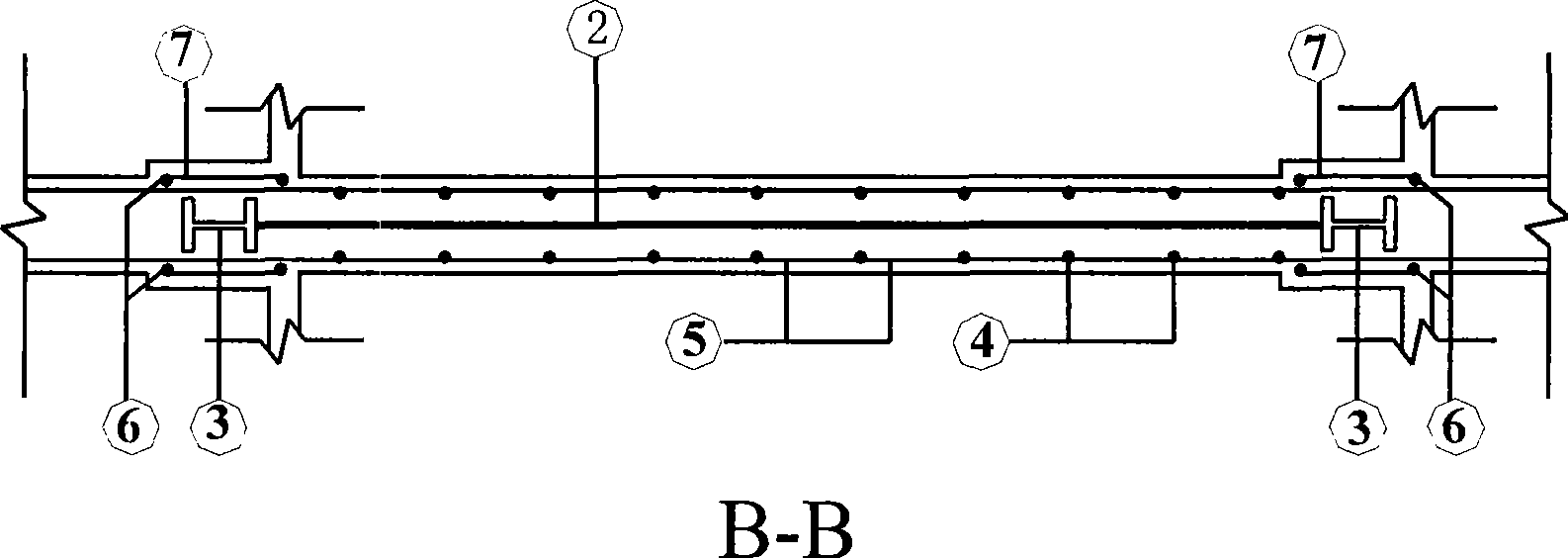

[0022] Schematic diagram of structural reinforcement of a structural unit of CFST-opened steel plate-concrete composite shear wall figure 1 , figure 2 with image 3 shown. There is no reinforcement in the steel pipe concrete frame column 1; the frame beam of the shear wall is the longitudinal reinforcement 6 of the frame beam arranged around the steel beam 3; holes are opened on the steel plate 2 of the shear wall, and the opening form is shown in the figure. The reinforcement of the shear wall panel is: on both sides of the width direction of the wall panel, the transverse reinforcement 4 and the longitudinal reinforcement 5 of the shear wall panel are evenly arranged horizontally and vertically respectively, and are bound and fixed at the intersection points to form two pieces of reinforcement mesh. The transverse reinforcement 4 is inserted into the concrete-filled steel pipe frame column 1 (perforated on the side wall of the column) for anchorage; finally, the frame col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com