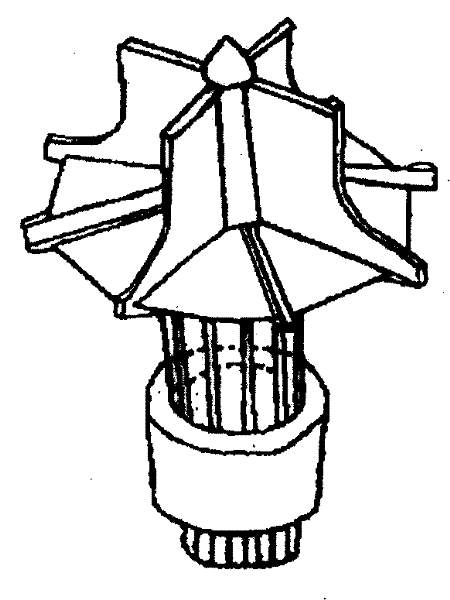

Reverse umbrella type oxidation ditch aeration machine impeller structure

The technology of aerator and oxidation ditch is applied in the structural field of the impeller of the inverted umbrella type oxidation ditch aerator, which can solve the problems of aggravating the energy crisis and the high operation cost of sewage treatment facilities, and achieves high structural efficiency, mechanical strength and durable life. High, enhance the effect of oxygenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] according to Figure 5 For the size of the aerator shown, the aerator is reduced by 40 times, and the aerator model of the same structure is made ( figure 1 As shown), the three aerators developed by Guozhen were also scaled down in the same scale to make aerator models ( Figure 2-4 shown). The aerator model was used to test the flow state in the oxidation ditch of the small test model, and the results showed that the plug flow and aerator performance of the aerator were better than the other three aerator structures (Table 1).

[0028] Table 1 Small test model flow rate comparison

[0029] Upper level horizontal speed Upper level vertical speed Lower level horizontal speed Lower level vertical speed

[0030]The present invention 0.00032757 -0.020277 -0.0076853 -0.0068225

[0031] in the upstream channel

[0032] Ds380 -0.00028131 -0.023339 -0.0059433 -0.0089323

[0033] close to exposure

[0034] Single layer 0....

Embodiment 2

[0062] The aerator with this structure and the other three aerators of Guozhen are used to simulate the actual oxidation ditch, and the calculation fluid dynamics model is used to simulate the push flow and aeration function of the aerator with the actual size structure. As can be seen from the test results, the performance of the aerator configuration proposed by the invention is better than that of the above three aerator configurations. Under the same rotating speed and input power conditions, the aerator configuration of this configuration The average flow velocity and output power of different sections in the middle of the oxidation ditch are higher than those of the other three types of aerators ( Figure 8 ,Table 2).

[0063] Table 2 Output Power Comparison

[0064] model Ds380 Dss-19Y this invention single layer Power(kW) 84.8 82.9 95.14 78.5 Multiples of single-layer aerator power 1.08 1.056 1.21 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com