Strand winding apparatus of heavy caliber pipe winder

A technology for winding machines and pipes, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc. It can solve the problems of low reliability, large mechanical wear, large mechanical friction and wear, etc., and achieve accurate propulsion and structural Simple, the effect of overcoming friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

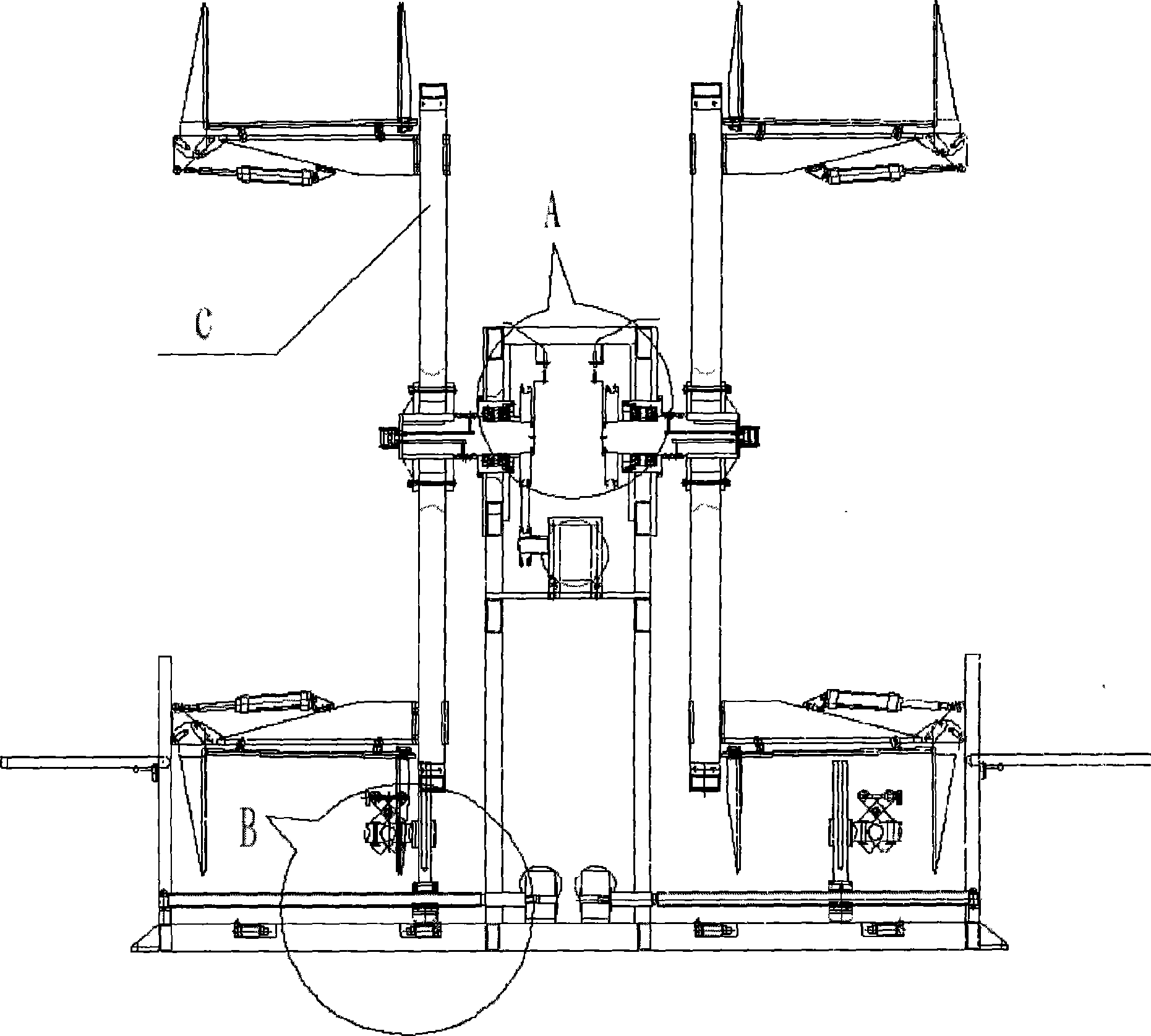

[0026] Structural schematic diagram of the present invention is attached figure 1 As shown, it is a winding machine part with a double reel structure, where the label A is the drive and induction mechanism of the reel, the label B is the cable arrangement mechanism composed of a wire screw rod, a cable device, etc., and the label C is the winding mechanism. reel.

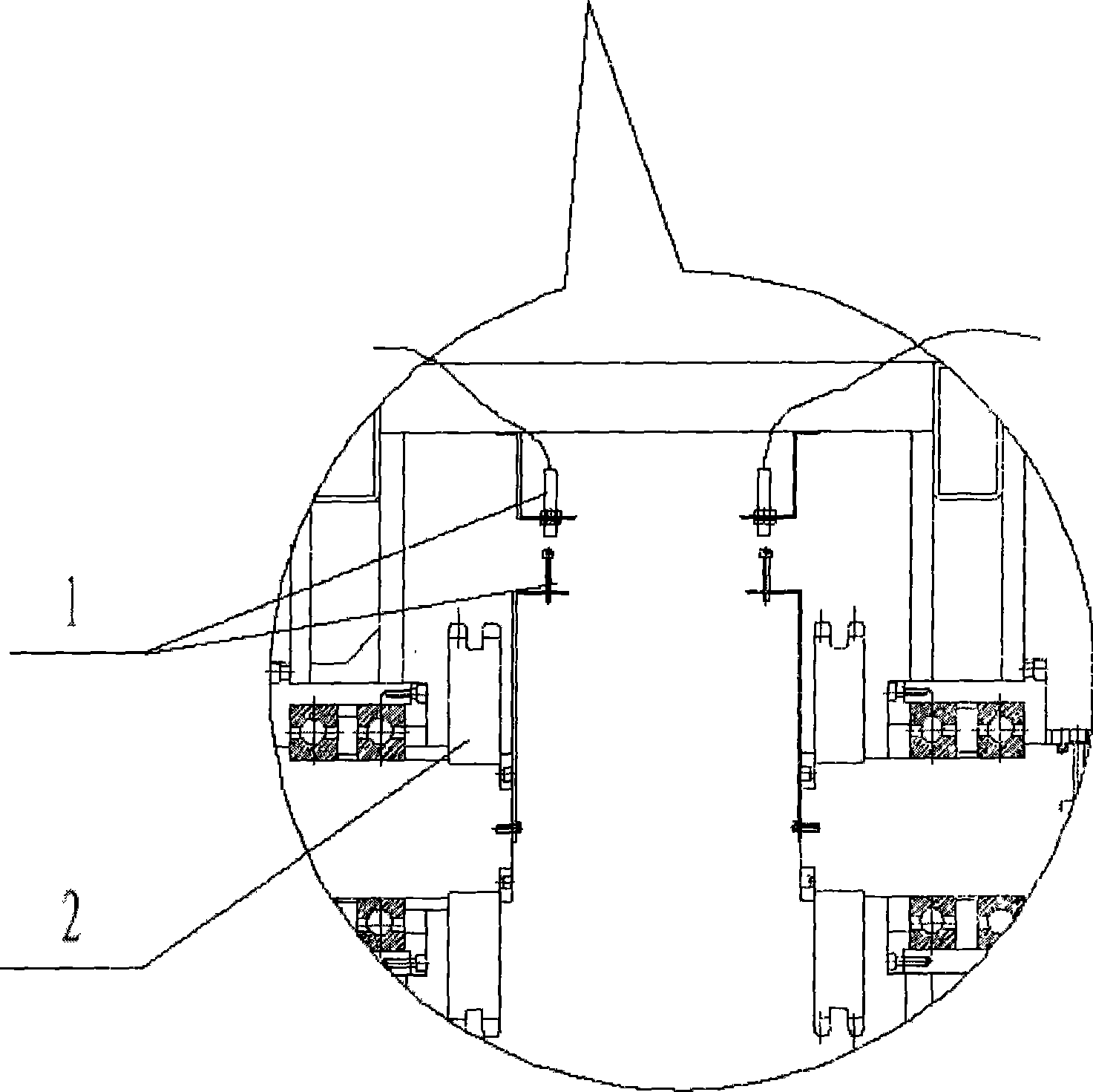

[0027] The drive and induction mechanism of the winding reel are attached figure 2 As shown, it includes a transmission gear 2 as a driving mechanism, and an induction electric eye 1 that rotates once as an induction winding reel, and the induction electric eye is also connected to the wire winding motor 3 of the wire winding mechanism through a lead wire.

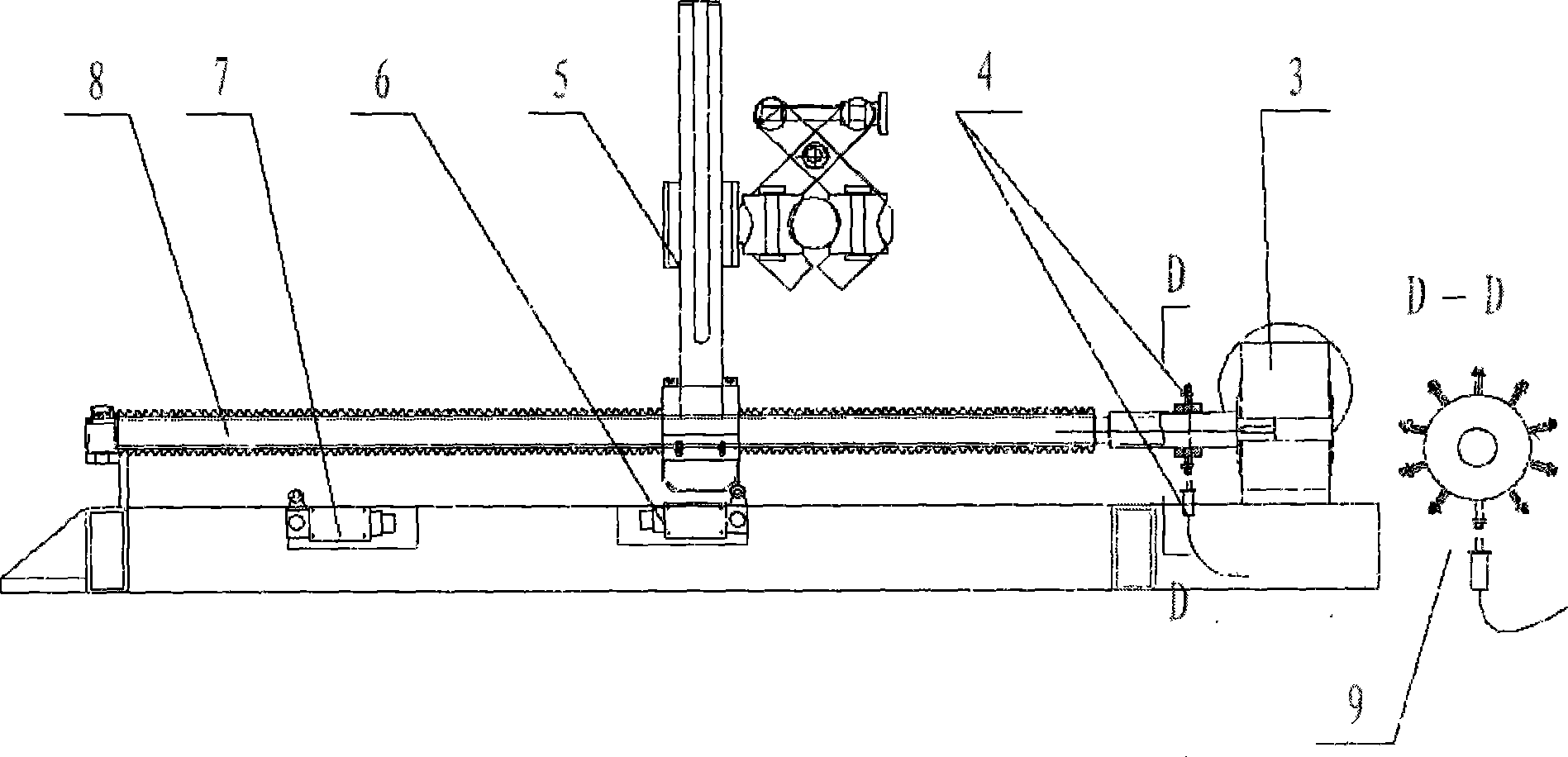

[0028] The structure of the wiring mechanism is attached image 3 As shown, it includes a cable motor 3, an induction electric eye detection 4, a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com