Metal porous membrane tube and preparation method thereof

A metal porous, membrane tube technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of reducing membrane tube permeability, unsynchronized sintering shrinkage, etc., to overcome sintering peeling, precision control layer Uniform and large penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

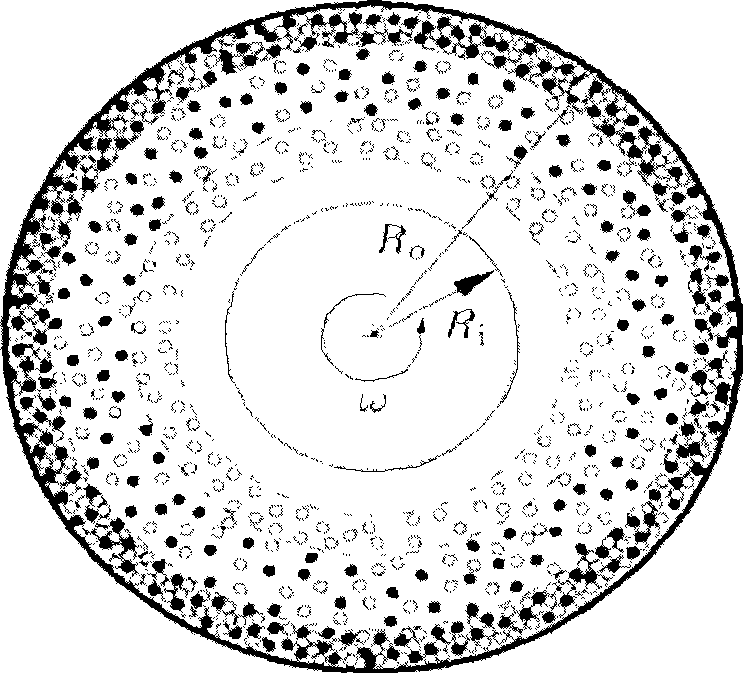

[0023] Weigh 80g of stainless steel powder with a particle size of 2.7μm, and prepare a powder suspension slurry with a pore size of 25μm and an air permeability of 130m 3 / (m 2 .h.Kpa) The outer wall of the porous support tube is covered with plastic, one end is sealed, the prepared slurry is loaded into the porous metal support tube from the other end, and then the other end of the porous support is sealed and fixed in the centrifugal cylinder. Start the centrifugal deposition device, and adjust the rotation speed from 0 to 6000 rpm for 300 minutes. The prepared stainless steel film, its microstructure is as follows figure 1 As shown, the average pore size of the medium flow in the precision control layer is 4.2 μm using the PMI capillary flow analyzer, and the relative air permeability of the filter tube is 100 m using the FBP-3I porous material tester. 3 / (m 2 .h.Kpa), the film thickness observed by scanning electron microscope is 100μm.

Embodiment 2

[0025] The steps are the same as in Example 1, the aperture of the porous stainless steel support tube is 25 μm, and the air permeability is 130 m 3 / (m 2 .h.Kpa), weighing 40g of 2.7μm stainless steel powder, preparing stainless steel slurry, the porous stainless steel membrane tube produced, using the PMI capillary flow analyzer to test the average pore size of the precision control layer is 4.7μm, using FBP-3I porous The relative air permeability coefficient of the filter tube tested by the material tester is 120m 3 / (m 2 .h.Kpa), the film thickness observed by scanning electron microscope is 50μm.

Embodiment 3

[0027] The steps are the same as in Example 1, the aperture of the porous support titanium tube is 15 μm, and the air permeability is 70 m 3 / (m 2 .h.Kpa), weighing -500 mesh titanium powder 40g, preparing titanium powder slurry, the prepared titanium porous membrane tube, using PMI capillary flow analyzer to test the average pore size of the precision control layer is 0.7 μm, using FBP-3I The relative air permeability coefficient of the filter tube tested by the type porous material tester is 70m 3 / (m 2 .h.Kpa), the film thickness observed by scanning electron microscope is 100μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Relative air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com