Spinning machine with time-dependent rotational speed control

A speed control and spinning machine technology, which can be used in continuous winding spinning machines, spinning machines, open-end spinning machines, etc., and can solve problems such as large time overhead.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

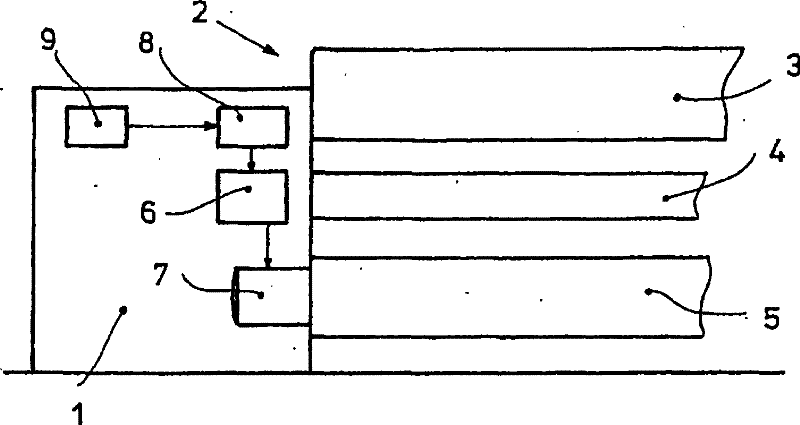

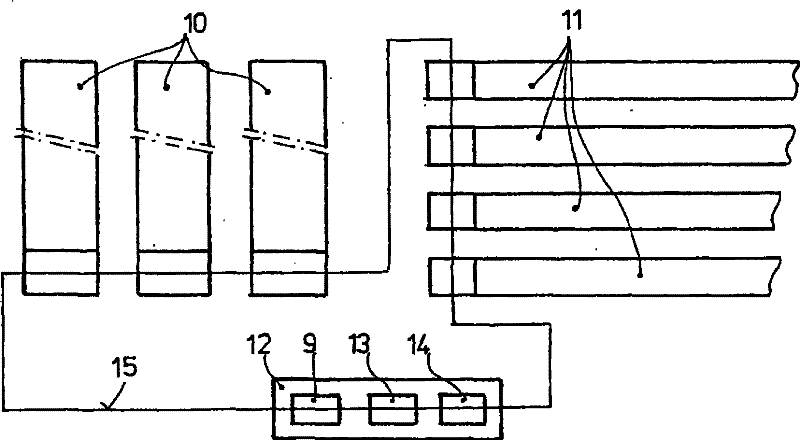

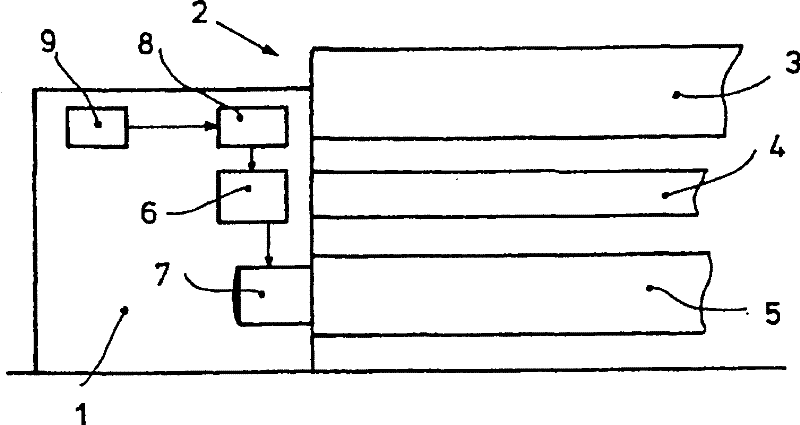

[0015] figure 1 Purely schematically shows, for example, a drive head 1 of a ring spinning machine 2 with a creel 3 , a drafting device 4 and a spindle zone 5 , the ring spinning machine 2 having at least one drive motor 7. The drive motor 7 is supplied by a feed device such as an inverter 6 . Of course, ring spinning machines usually have several motors, which are not shown here.

[0016] The rotational speed of the motor 6 or motors can be determined in a variable manner via the rotational speed supplied to the frequency converter 6 by a rotational speed selector 8 (encoder) arranged in the machine control. With the aid of a manually set speed selector, the motor speed can usually be selected within a wide range as described above.

[0017] According to the invention, the ring spinning machine 2 is equipped with timing means 9 by means of which the rotational speed selector 8 can be set to at least one other rotational speed within a certain period of time.

[0018] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com