Mechanism for controlling position of optical element

A technology of optical components and control mechanisms, applied in the direction of optical components, optics, installation, etc., can solve the problems of unobtainable optical performance, and achieve the effects of low power consumption, space saving, and small load changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

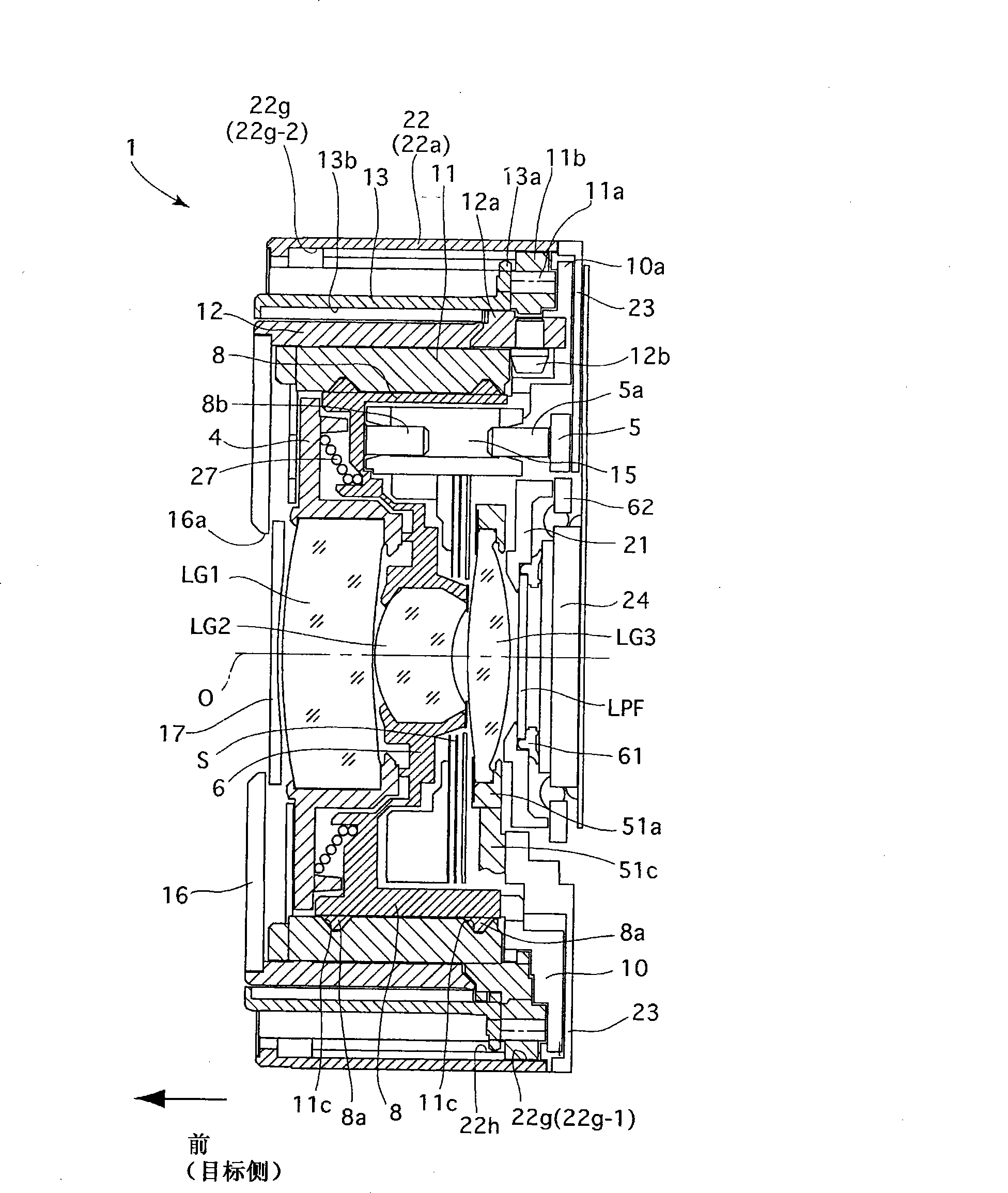

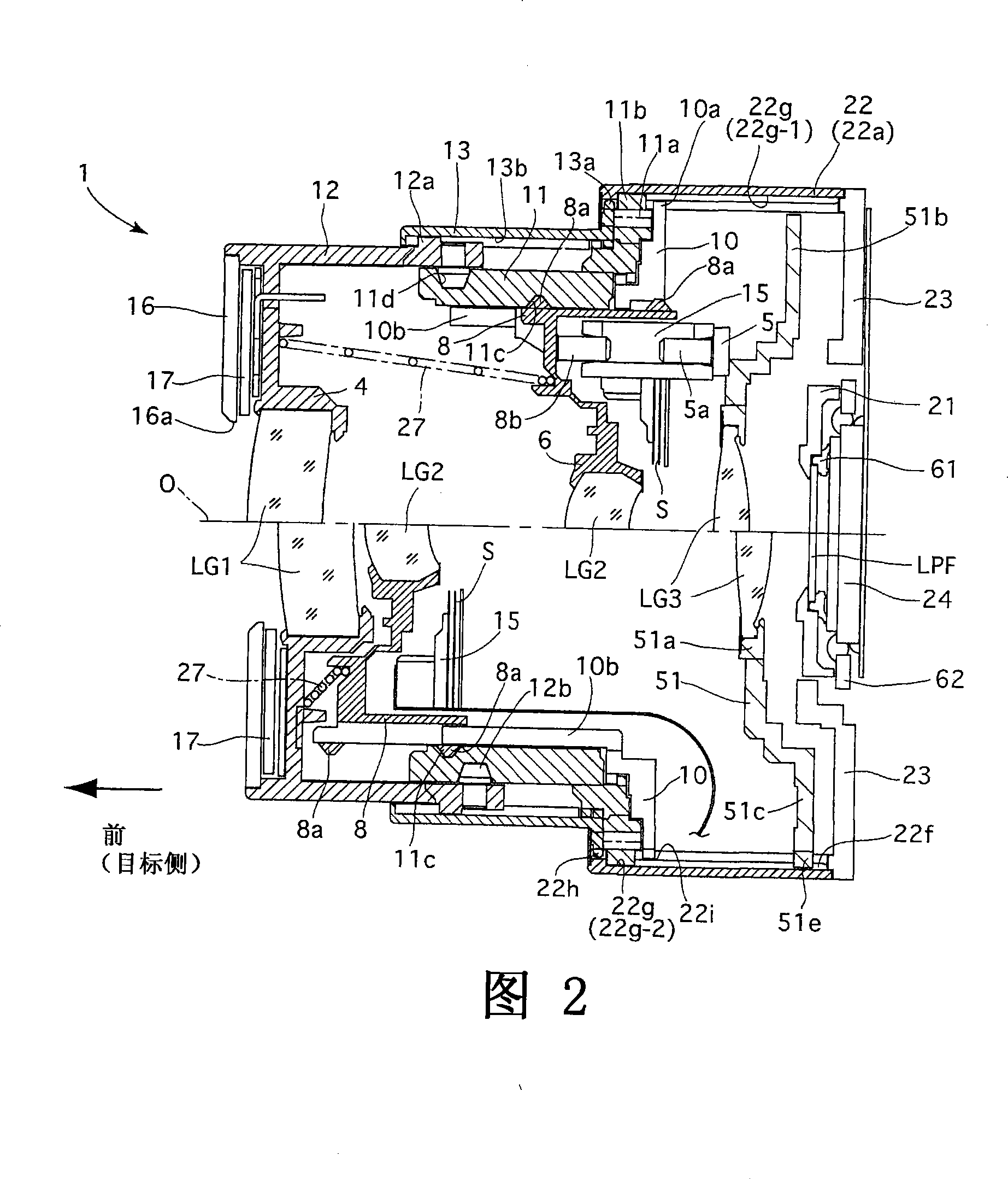

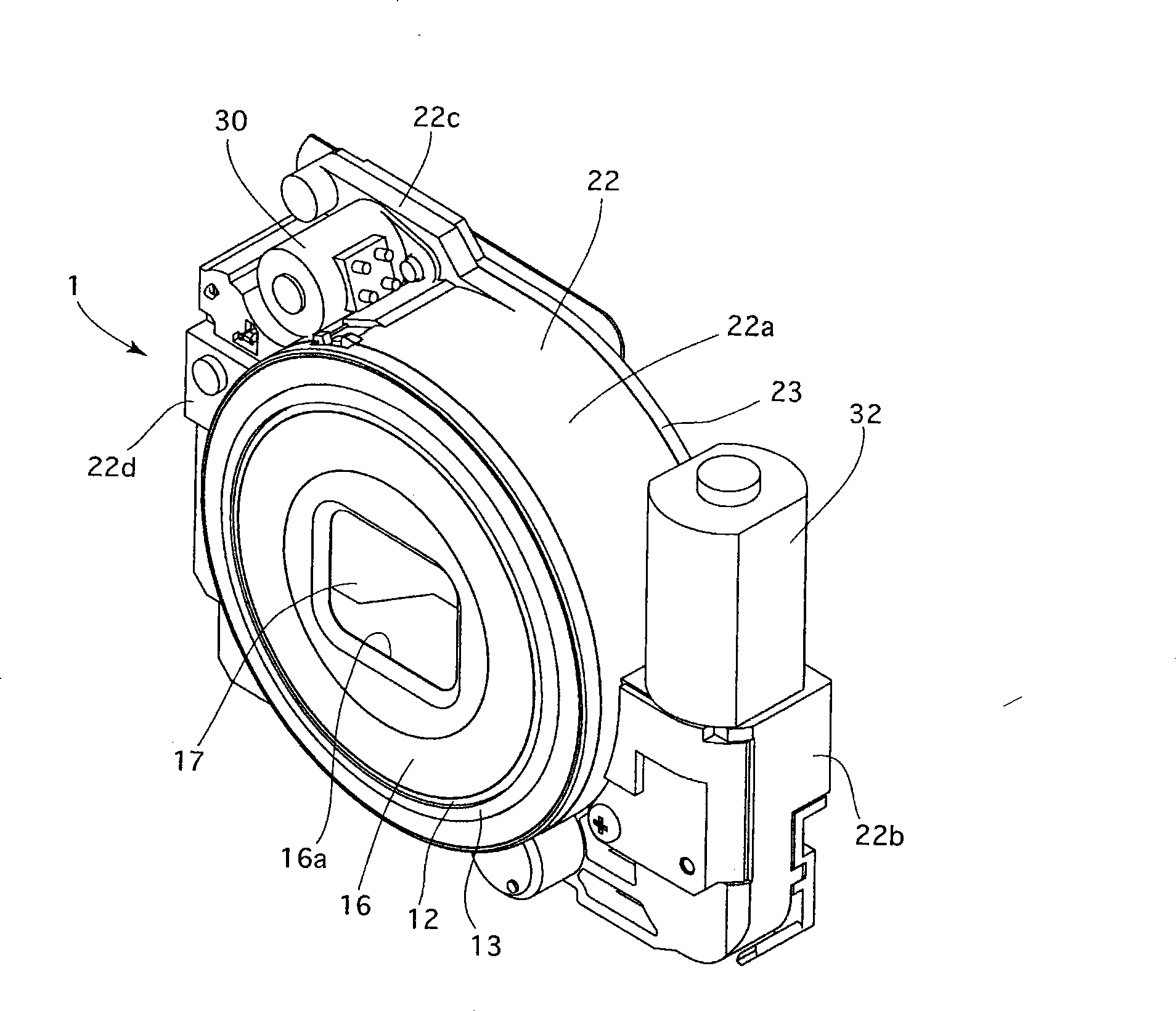

[0056] First, the following will mainly be based on figure 1 7 to discuss the overall structure of the zoom lens barrel 1 to which the optical element position control mechanism of the present invention is applied. figure 1 and Fig. 2 have provided the sectional view of zoom lens barrel 1 respectively, figure 1 It shows that the zoom lens barrel 1 is in the retracted state of the lens barrel, and no photos are taken in this state. The upper half of the sectional view in Fig. 2 shows that the zoom lens barrel 1 is at the wide-angle end, and the lower part of the sectional view in Fig. 2 Half shows the zoom lens barrel 1 at the telephoto end. image 3 with Figure 4 is a perspective view of the zoom lens barrel 1 in the lens barrel retracted state, Figure 5 with Image 6 It is a perspective view of the zoom lens barrel 1 in a ready-to-shoot state.

[0057] The zoom lens barrel 1 has a photographic optical system including, in order from the object side, a first lens group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com