Hydraulic damper with excellent leak tightness

A hydraulic damper and sealing technology, which is applied in the direction of liquid shock absorber, shock absorber, shock absorber, etc., can solve the problems of poor sealing, high processing cost, complicated assembly, etc., achieve good sealing performance and improve service life , the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

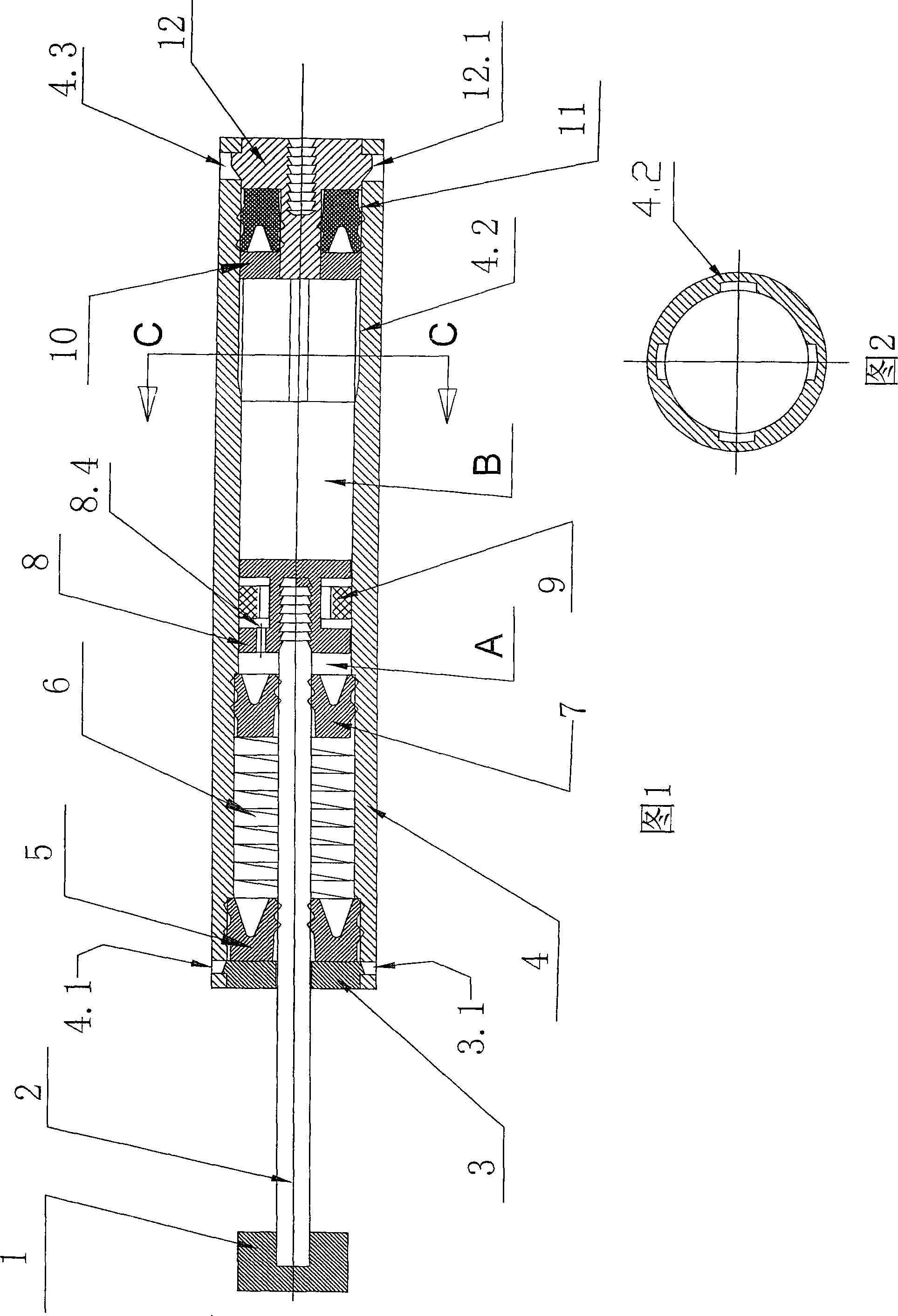

[0059] Referring to Fig. 1, the present invention relates to a hydraulic damper with excellent sealing performance. The damper is specifically a closed cylinder 4, and the inner chamber of the cylinder 4 is divided into a first cylinder 4 by a piston 8 that can slide in the cylinder 4. Studio A and a second studio B. The first working chamber A and the second working chamber B are separated by the piston 8 and filled with a hydraulic fluid.

[0060] The damper has a piston, a piston rod 2 which is led out of a cylinder 4 through a first working chamber A in a sealing manner, the end of which is connected to the front connecting piece 1 .

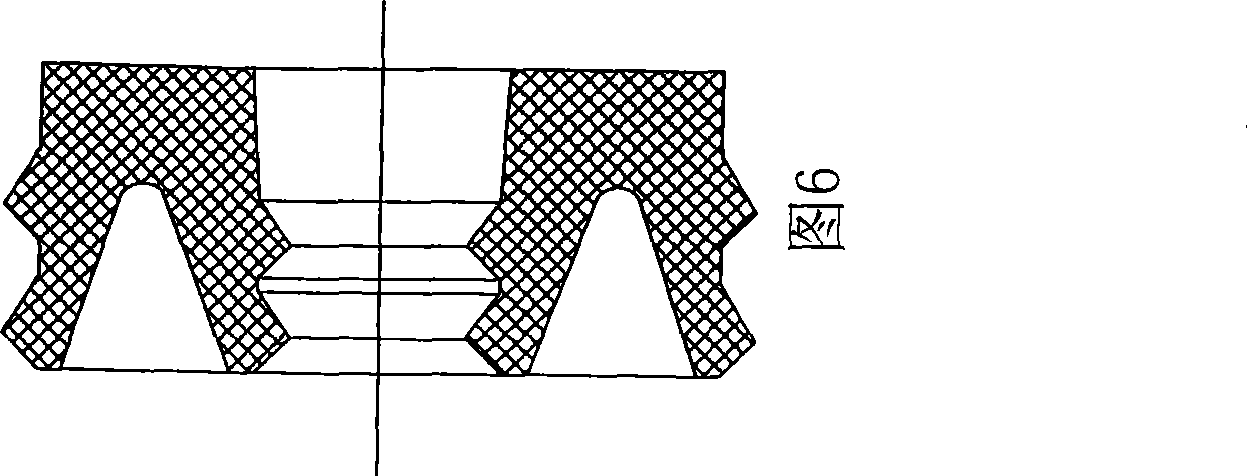

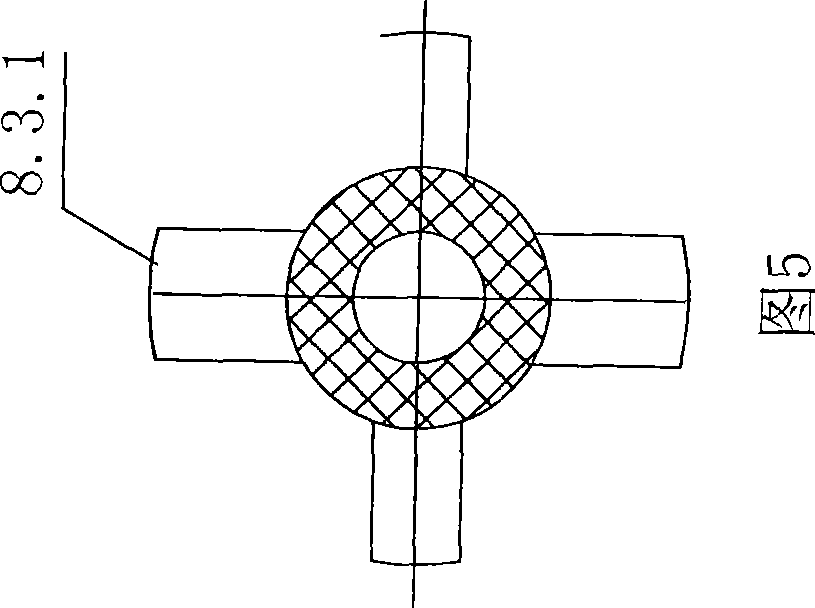

[0061] A guide sleeve 3, a front leather cup 5, a spring 6 and a middle leather cup 7 are closely arranged in the cylinder body 4 between the piston 8 and the leading end of the piston rod. The guide sleeve 3 is arranged close to the leading end of the piston rod. , The middle cup 7 is set close to the piston 8.

[0062]At least two protru...

Embodiment 2

[0068] Referring to Fig. 7, the difference between the present embodiment and the first embodiment is that the spring of the elastic element 6 is replaced by a sponge, and the center of the sponge is provided with a support 13 sleeved on the shaft to ensure that the sponge is not compressed in the axial direction. Leather cup 7 in example one is used retaining ring 7 instead, and retaining ring 7 does not need sealing with cylinder body cylinder wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com