Method to determine the fuel temperature in a common rail injection system

A technology of injection system, fuel temperature, applied in the application of thermometer, temperature measurement in motor, thermometer, etc., to achieve the effect of accurate and stable electronic regulation, reduce cost and error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

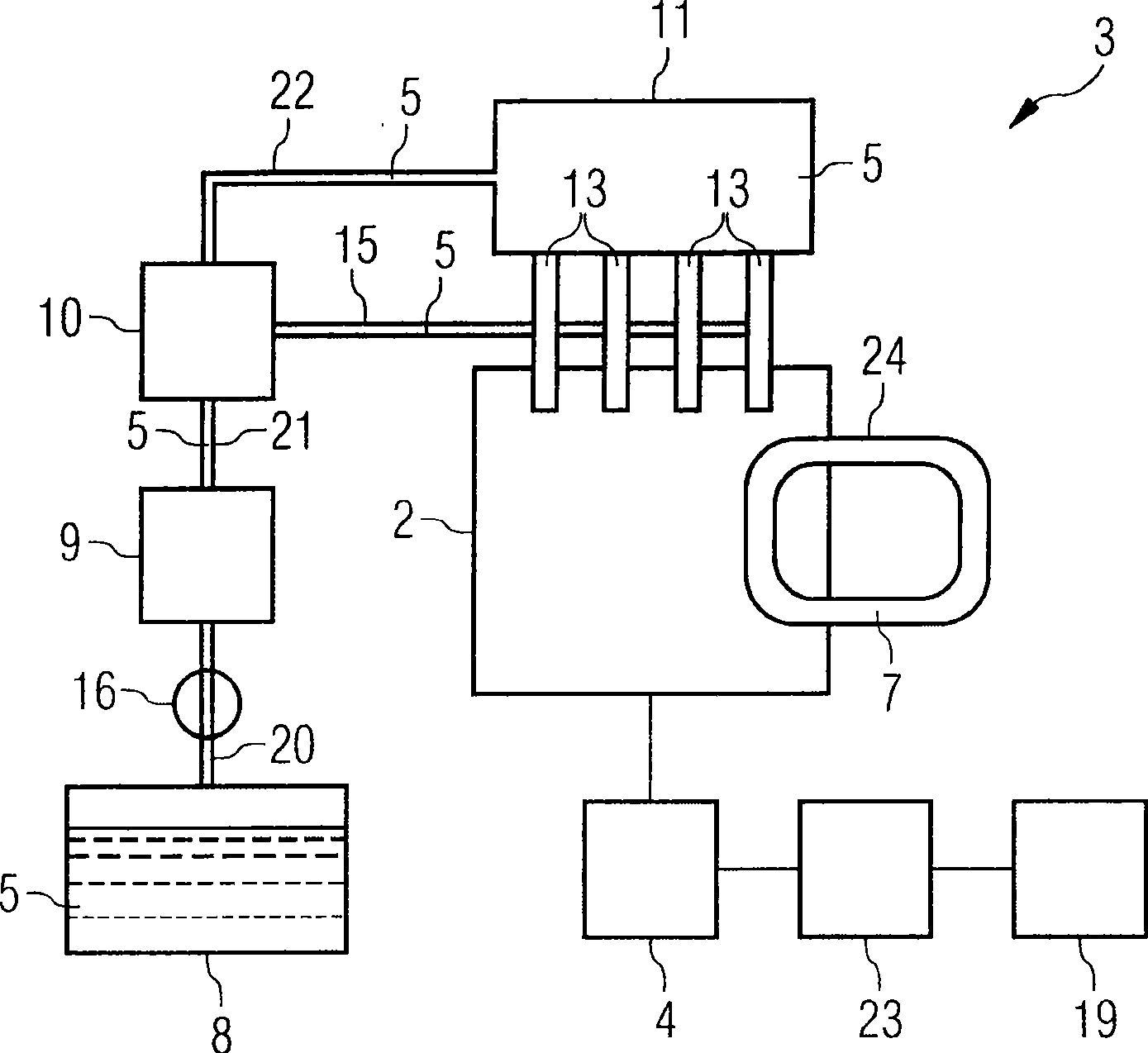

[0022] figure 1 A schematic diagram of a common rail injection system 3 that can be used with the engine 2 is shown. Fuel 5 flows from fuel tank 8 via first fuel line 20 to backing pump 9 of high-pressure pump 10 . The backing pump 9 pumps fuel 5 to the high-pressure pump 10 via the second fuel line 21 . The high-pressure pump 10 pumps the fuel 5 to the common rail 11 at high pressure FPSP via the third fuel line 22 . Fuel 5 is injected into engine 2 from common rail 11 through several injectors 13 . Fuel leakage at the injector 13 is conveyed back to the high-pressure pump 10 via a leakage line 15 .

[0023] The engine 2 is connected to a cooling water circuit 24 . The cooling water 7 circulating in the cooling water circuit 24 is used to cool the engine 2 . The temperature TCO of the cooling water 7 can be used to measure the temperature of the engine 2 .

[0024] The engine 2 is connected to an engine control unit 4 . The engine control unit 4 is connected to a tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com