Inverse drainage processing method in high concrete panel rock-fill dam construction period

A technology for concrete face and drainage treatment, which is applied in the direction of dams, barrages, weirs, etc., and can solve problems such as large dam volume, interference with dam construction, and impact on dam safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

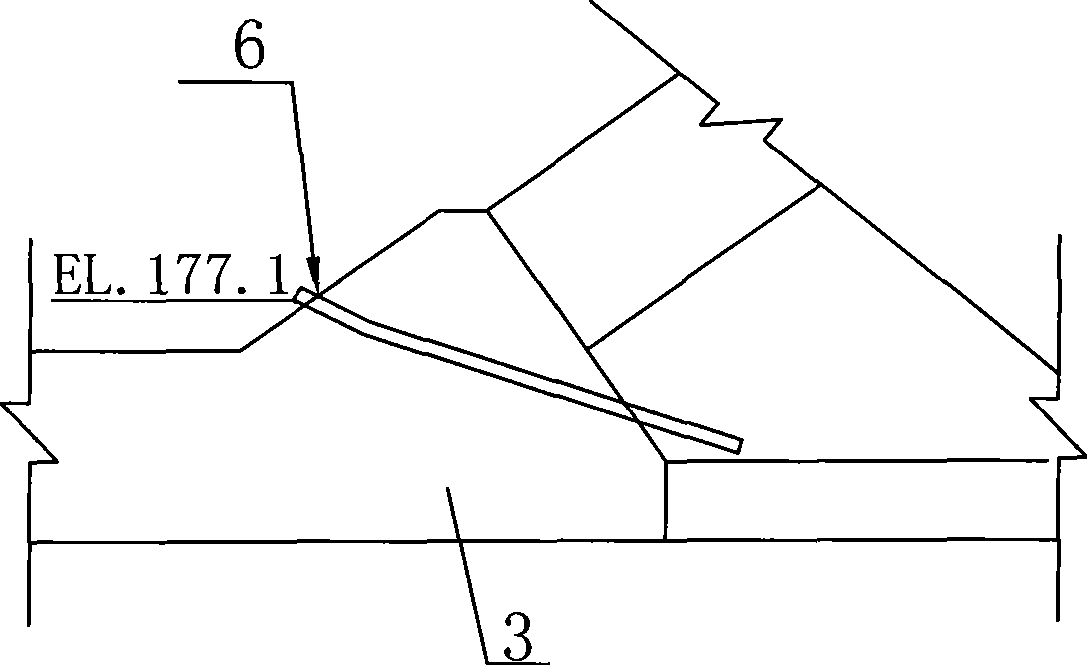

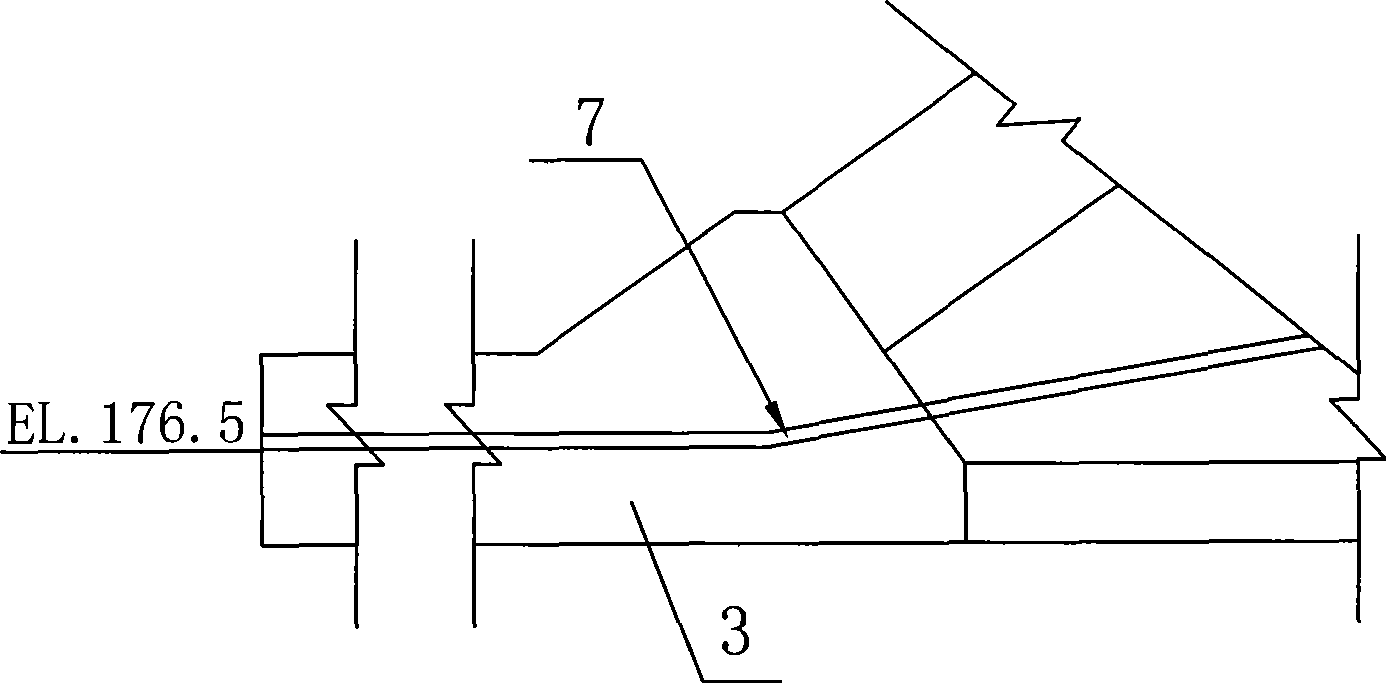

[0020] For a concrete face rockfill dam with a dam height of 233m, during the construction period of the dam body, the abandoned water and underground seepage water were drained out of the dam by using the conventional drainage method combined with the drainage of the plinth wide groove. The first is to use the wide groove of the toe board for the dam construction waste water below the weir crest elevation of the water measuring weir behind the dam, and use the wide groove of the toe board, and use the reinforced gabion in the rockfill body in front of the dam to set up a temporary water collection well and erect a drainage pipe to drain the reverse osmosis water The second is to use the conventional water-measuring weir behind the dam to discharge water and underground seepage in the dam body above the weir crest elevation of the water-measuring weir behind the dam. The specific construction process is as follows:

[0021] (1) Drainage system layout in front of the dam

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com