Automotive floor skirt beam for alternation type overlap joint soldering

A staggered, overlapping edge technology, applied in vehicle components, superstructure, superstructure sub-assemblies, etc., can solve problems such as difficulty in forming parts, dangerous occupant life safety, engine intrusion into the passenger compartment, etc., to improve bending stiffness and Torsional stiffness, the effect of ensuring comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

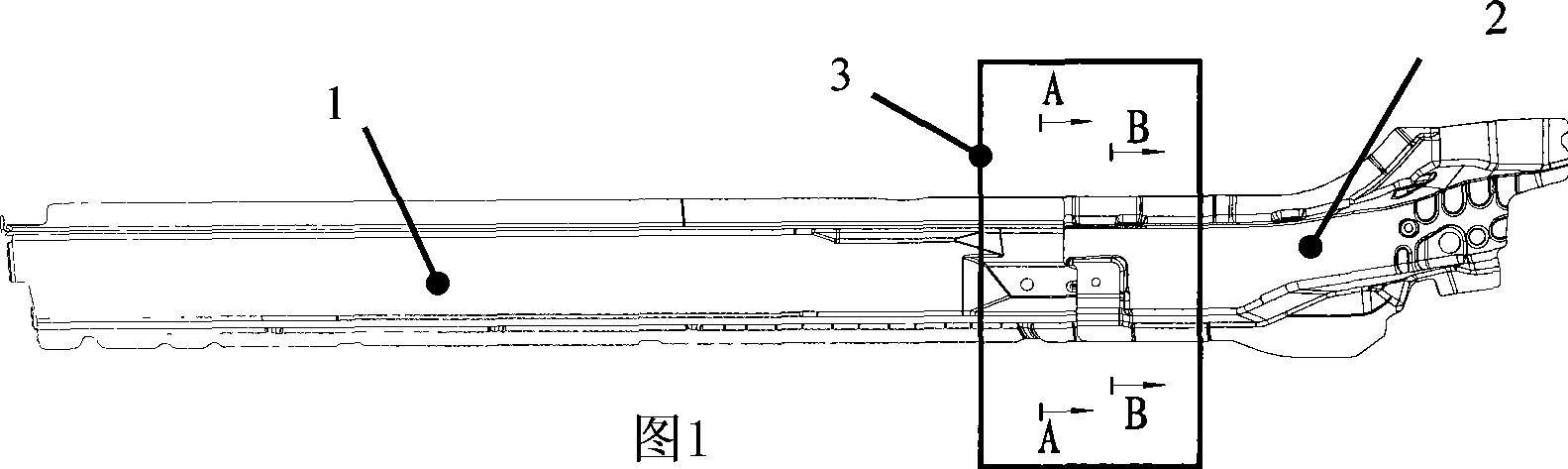

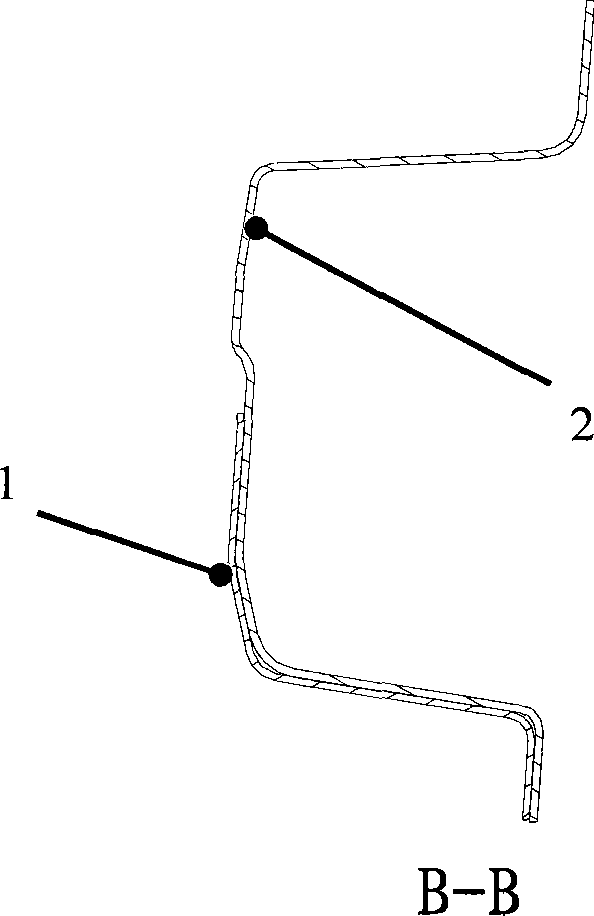

[0015] See Figure 1, Figure 1A and Figure 1B , taking the left side beam as an example, the floor side beam of the car is divided into two sections, the front floor side beam left 1 and the rear floor side beam left 2. This staggered lap joint structure is to form an X shape at the welding ends of the two side beams For overlapping edges, the two overlapping edges are welded together alternately to form the staggered overlapping area shown at 3 in FIG. 1 .

[0016] The specific welding fit process will be figure 2 , fix the front floor side beam left 1 in this design on the fixture through the front floor assembly where it is located, and drop the rear floor side beam left 2 through the rear floor assembly where it is located along the negative Z direction, and then pass through figure 2 From (a), (b), (c) shown in (a), until the completion of (d), the left 1 of the front floor side beam and the left 2 of the rear floor side beam are similar to a guide mechanism, which fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com