Positioning split type auxiliary frame work steering frame

A bogie, split-type technology, applied in the direction of the device for lateral relative movement between the undercarriage and the bogie, can solve the problems of large unsprung mass, increased wheel-rail wear, and wheel-rail wear, so as to reduce the wheel-rail effect force, save maintenance cost, and reduce the effect of wheel and rail wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

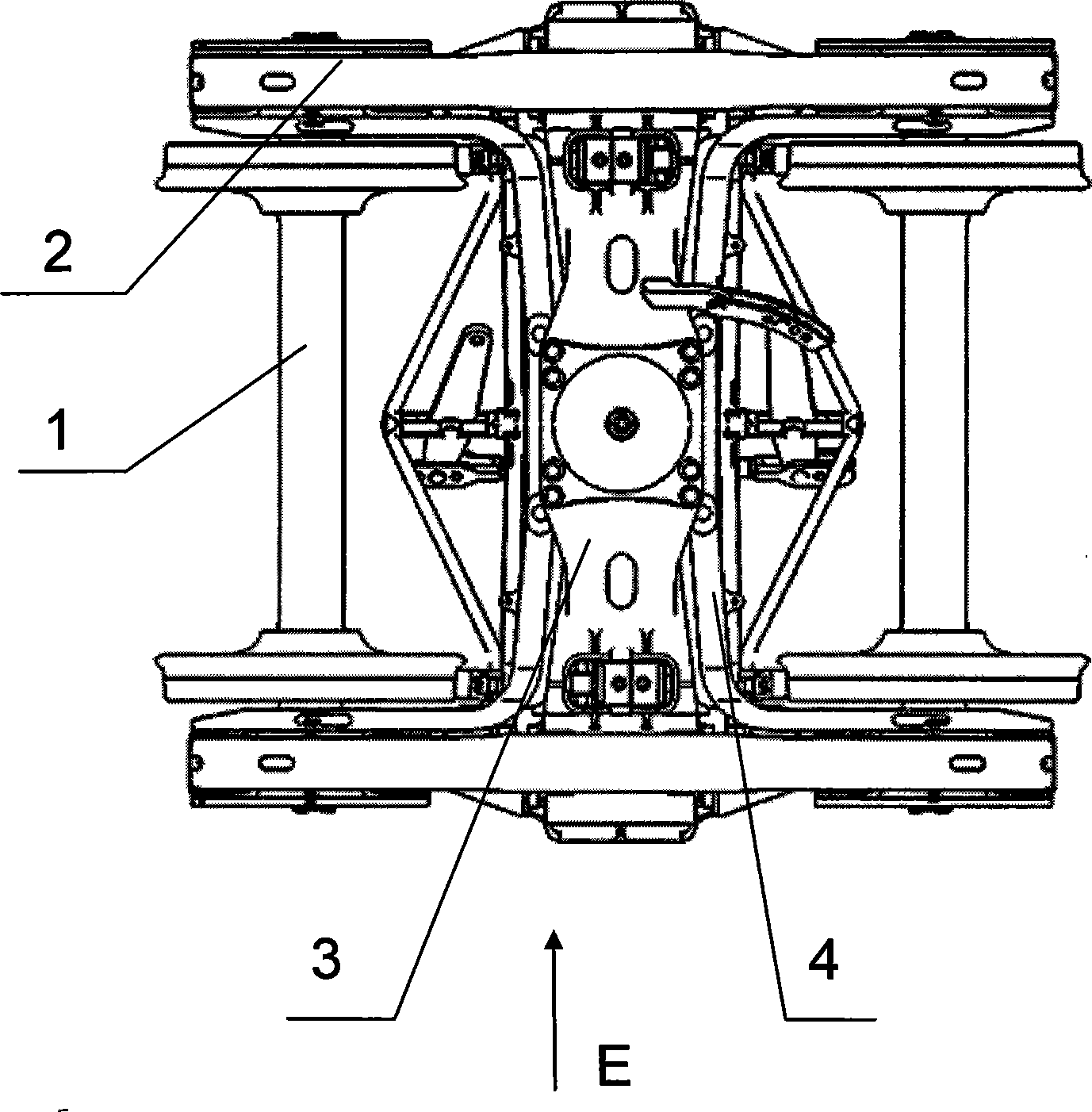

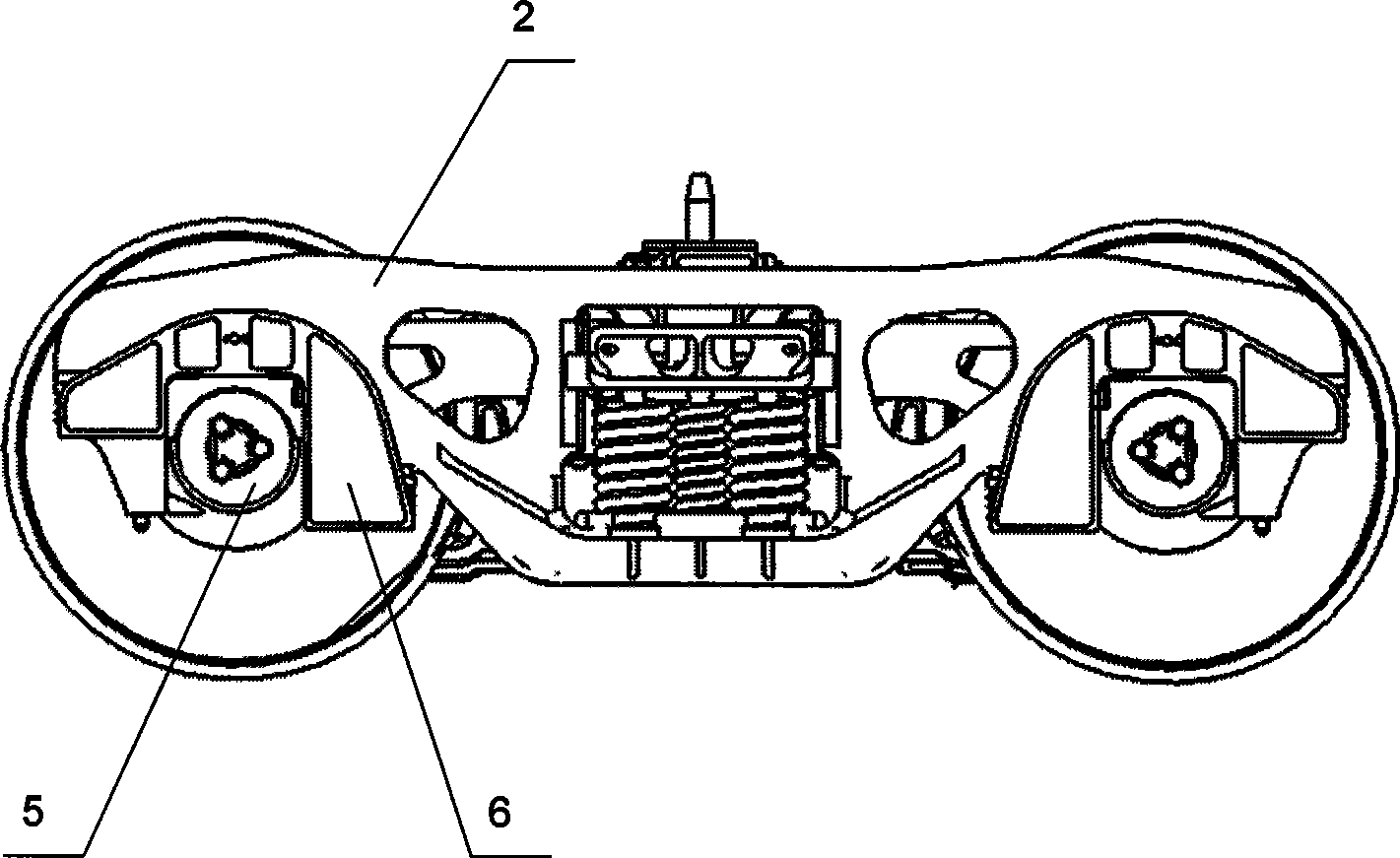

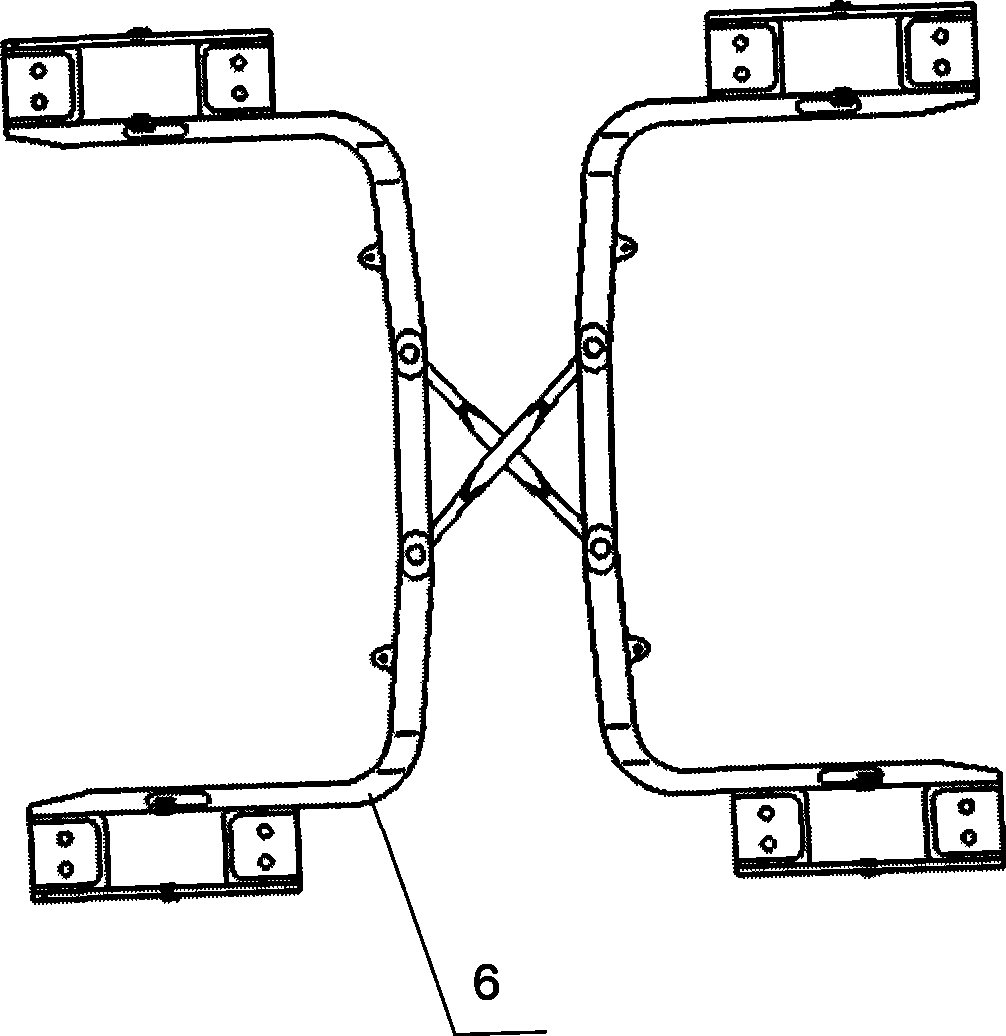

[0017] see figure 1 — Figure 8 , the present invention comprises two wheel pairs 1, side frames 2, bolsters 3 and wheel pair radial devices 4, the two ends of the wheel pair 1 are press-fitted with rolling bearing devices 5, and the four rolling bearing devices 5 on the two wheel pairs 1 are mounted with wheels For the radial device 4 , the side frame 2 is fitted on the radial device 4 of the wheel set, and the radial device 4 of the wheel set includes two U-shaped sub-frames 6 . The key technology is that the U-shaped sub-frame 6 is positioned and assembled by the U-shaped sub-frame body 7 and the bearing saddle 8 . Specifically, the positioning surfaces A, B, and C are respectively processed on the U-shaped sub-frame body 7. The A surface is located on the U-shaped bottom plane of the U-shaped sub-frame body 7, and there are positioning protrusions on both sides of the U-shaped bottom plane. The platform 11 and the two positioning surfaces of the positioning boss 11 are B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com