Wire-electrode cutting electromachining machine tool for asymmetrical guide frame notch cutting in series

An asymmetric, tandem technology, used in electric machining equipment, metal machining equipment, electrode manufacturing, etc., can solve problems such as time-consuming and low machining efficiency, reduce operation time and difficulty, improve grooving quality, and improve The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described below in conjunction with accompanying drawing.

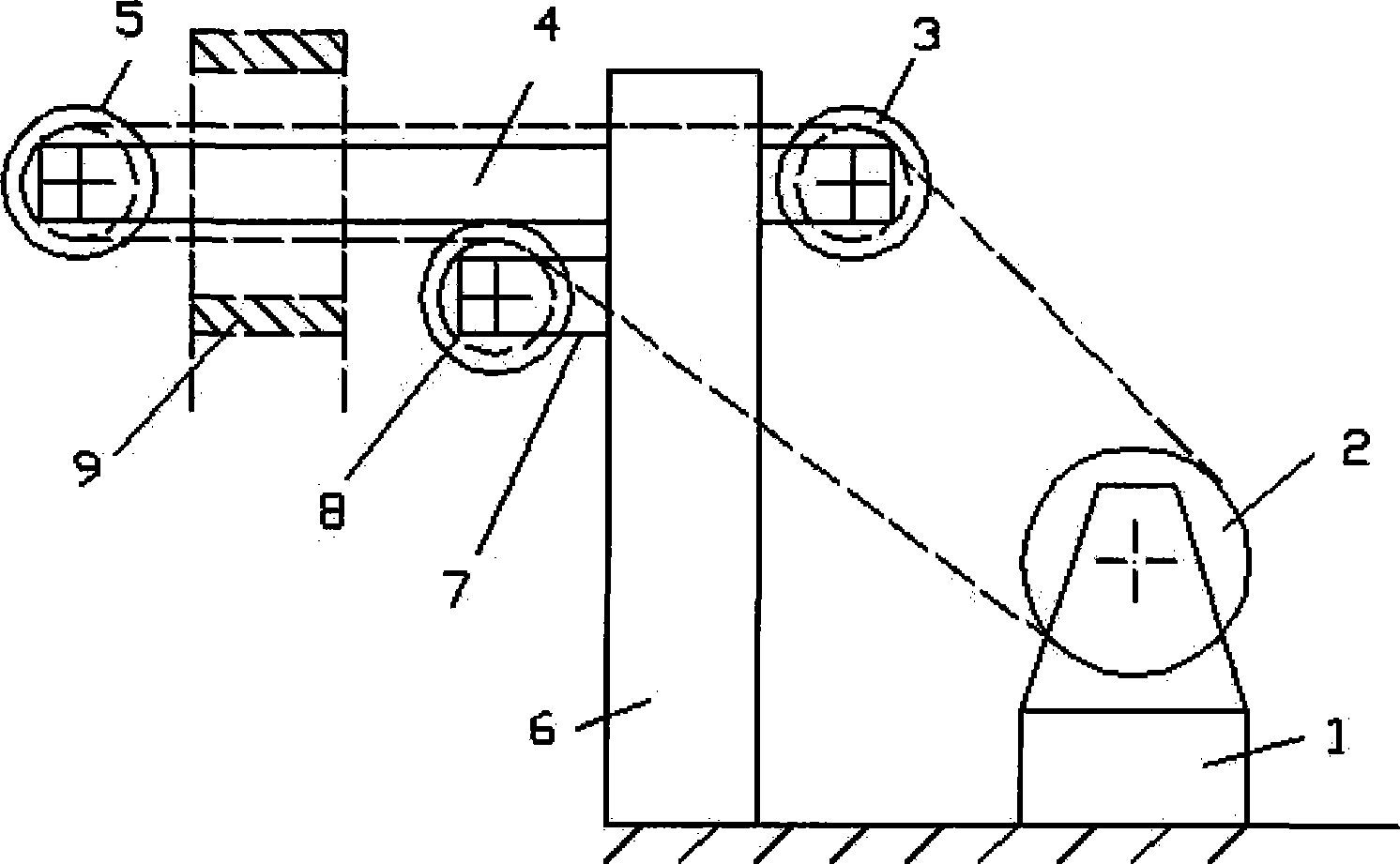

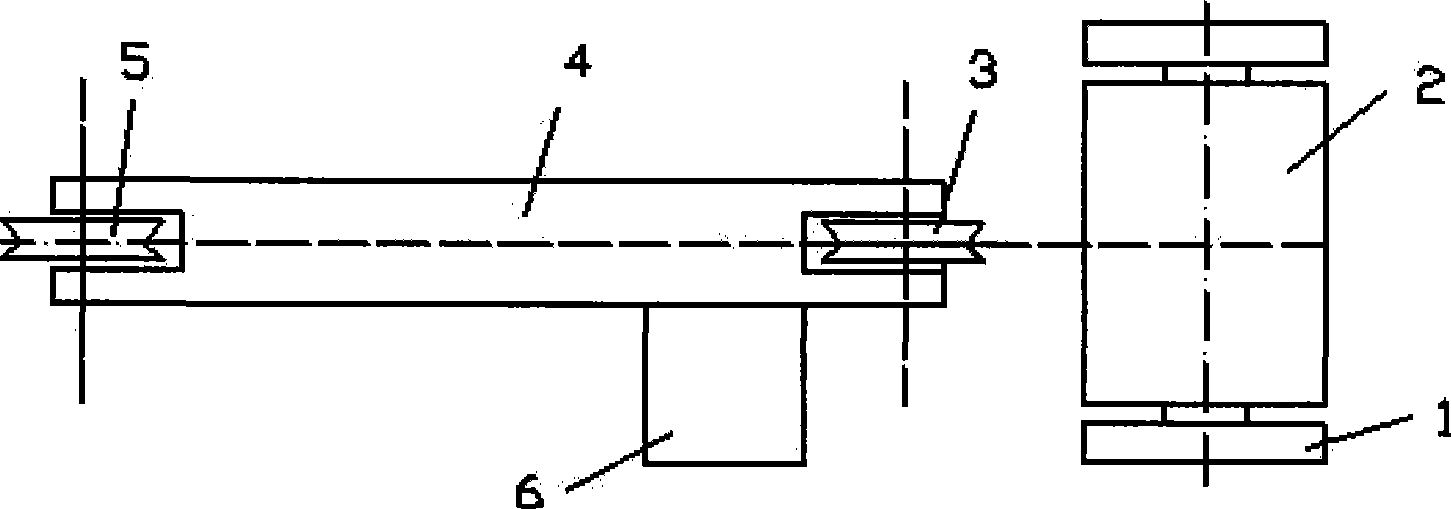

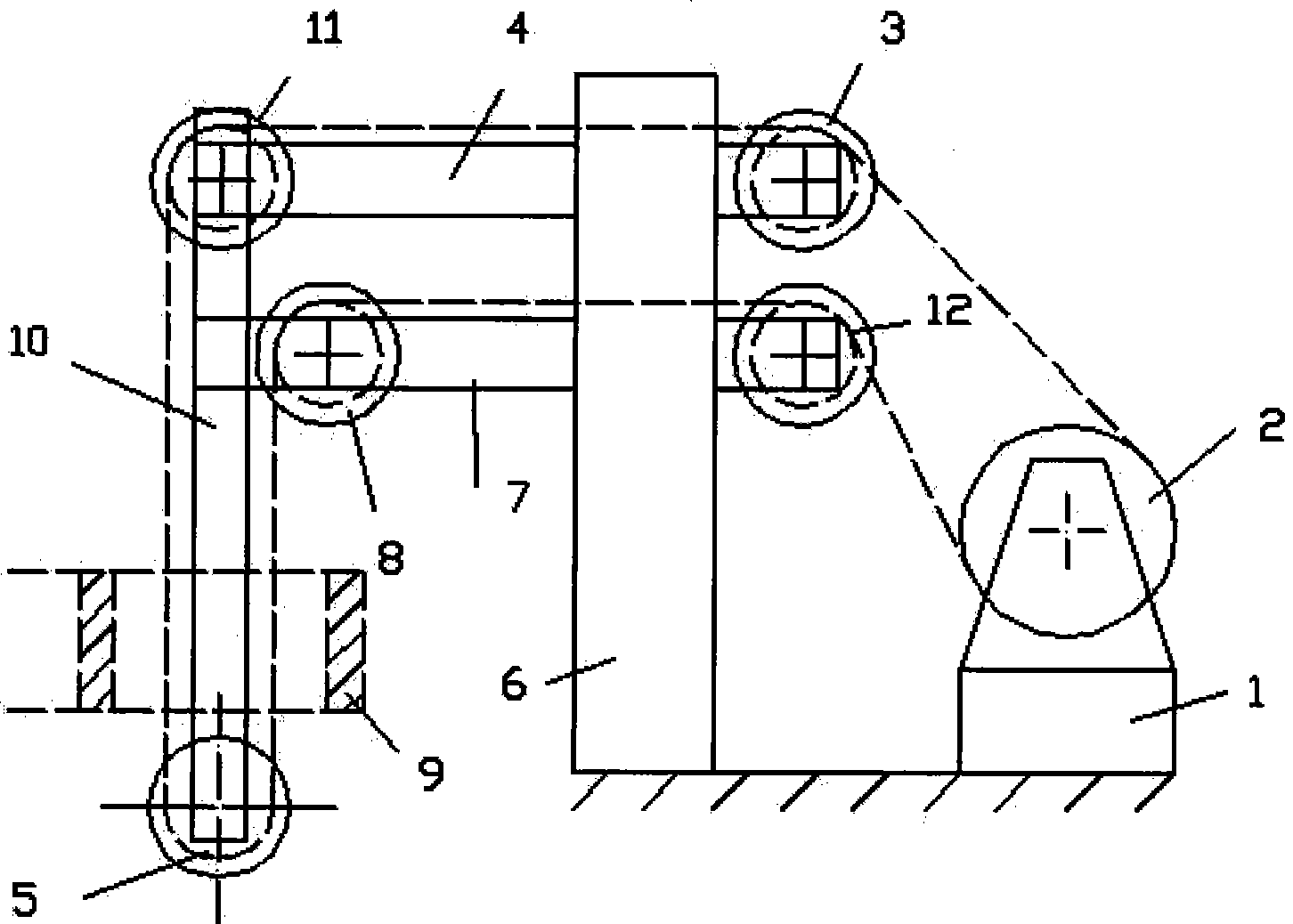

[0039] exist figure 1 The wire cutting electric machine tool is used for grooving, the reel base 1 and the support column 6 are fixed on the bed of the machine tool, the reel 2 is fixed on the reel base 1, the main wire frame 4 is fixed on the support column 6, the main The back end of the wire frame 4 is fixed with a rear guide wheel 3, and the front end is fixed with a winding guide wheel 5; the auxiliary wire frame 7 is fixed on the support column 6 and is located below the main wire frame 4, and the auxiliary wire frame 7 is fixed with a directional guide wheel 8 ; The metal wire that comes out from the winding drum 2 passes through the workpiece 9 through the rear guide wheel 3, walks around the rewinding guide wheel 5, and returns to the winding wire drum 2 through the orientation guide wheel 8. The above-mentioned directional guide wheel 8 is parallel to the space plane of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com