Coiling temperature control device and control method

A technology of coiling temperature and control device, which is applied in the direction of temperature control, temperature control by electric means, etc., can solve the problems of undisclosed difference calculation time interval determination, excessive calculation amount, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

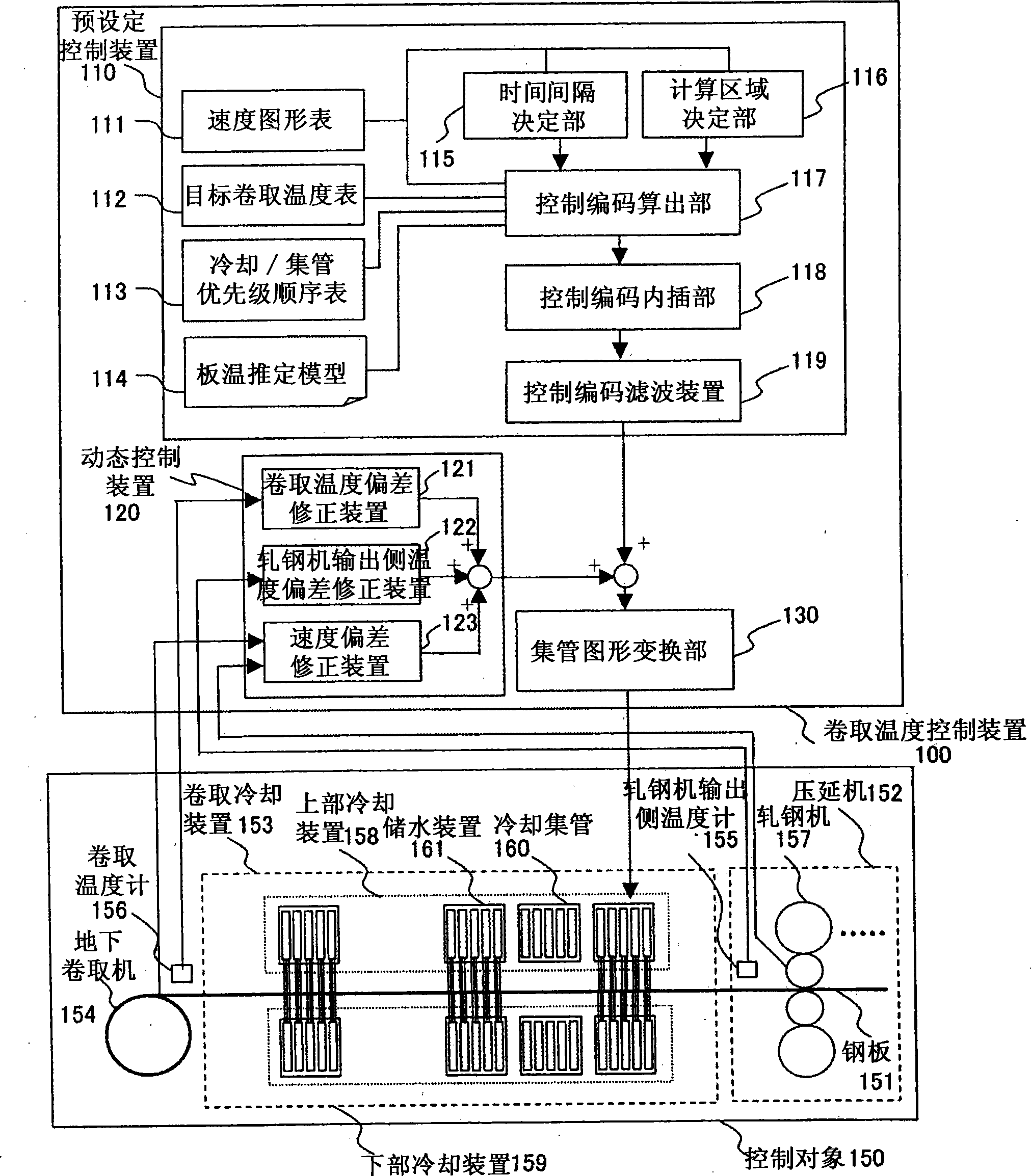

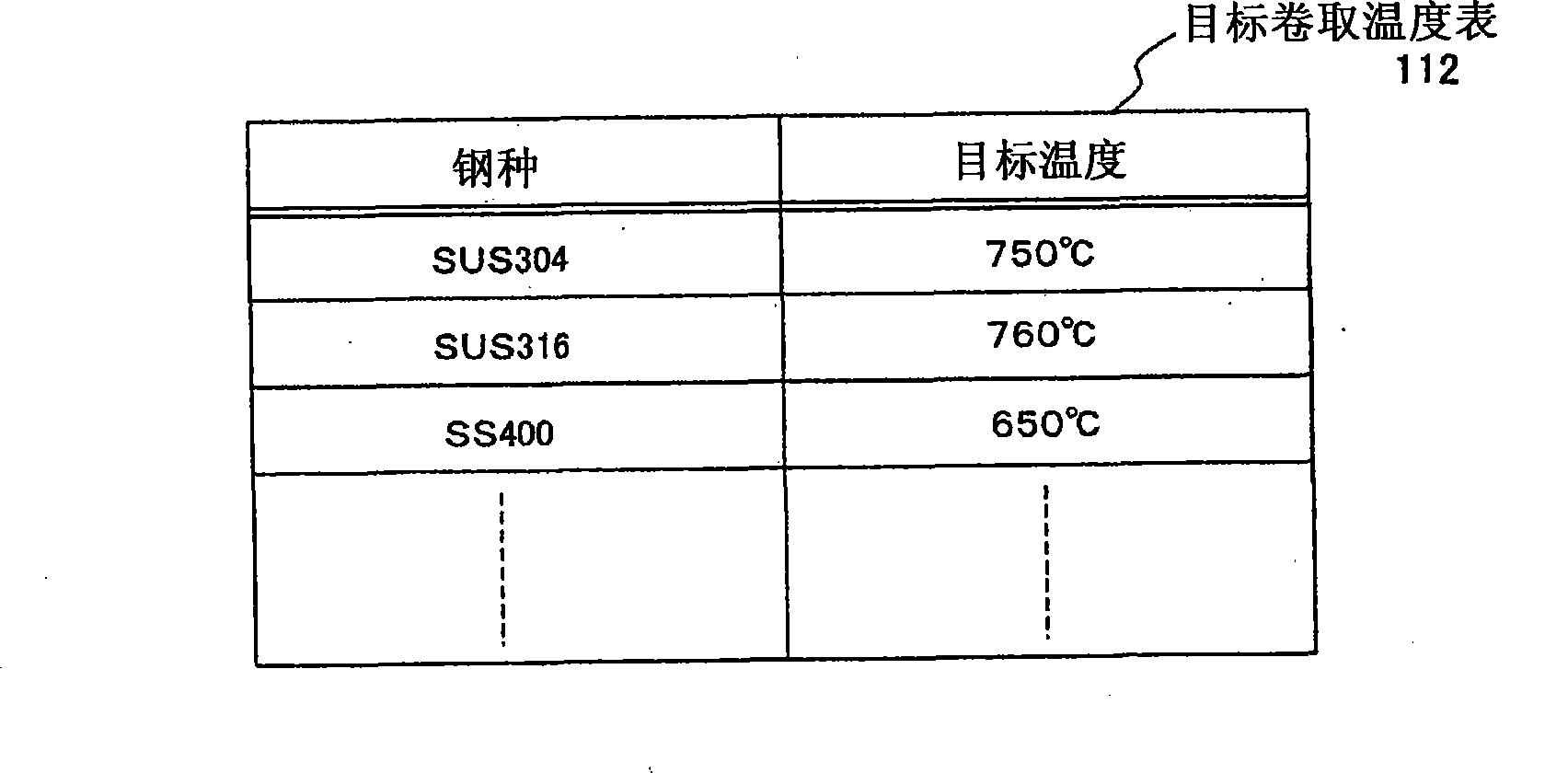

[0048] figure 1 An embodiment of the coiling temperature control system of the present invention is shown. The coiling temperature control device 100 receives various signals from the control object 150 and outputs a control signal to the control object 150 . First, the configuration of the control object 150 will be described. In this embodiment, the control object 150 is the coiling temperature control equipment for hot rolling. The coiling cooling device 153 is used to cool the steel plate 151 rolled by the rolling mill 157 of the rolling section 152 at a temperature of about 900° C. The coiler 154 coils. In the tandem rolling, rolling is performed continuously with about seven rolling mills, so the rolling mill 157 in the figure corresponds to the final rolling stand. In addition, there may be reciprocating rolling with one rolling stand like a steckel mill, and any of them can be applied to the present invention.

[0049] The coil cooling device 153 includes an upper ...

Embodiment 2

[0128] The following shows an example in which the time interval of difference calculation is optimized every time according to the current steel plate speed. Figure 16 The processing of the time interval determination unit 115 in this case is shown. The time interval determination unit 115 is activated every time a new calculation time is received from the control code calculation unit 117, and calculates and outputs the time interval. In S16-1, the current calculation time is read from the control code calculation unit 117, and the board speed at that time is calculated. In S16-2, the standard time interval is calculated according to the formula (2) according to the plate speed and the distance between the nozzles in the longitudinal direction of the steel plate. Then, based on the standard time interval, the time interval for difference calculation is calculated according to formula (3), and is output to the control code calculation unit 117 .

[0129] In Example 1, the ...

Embodiment 3

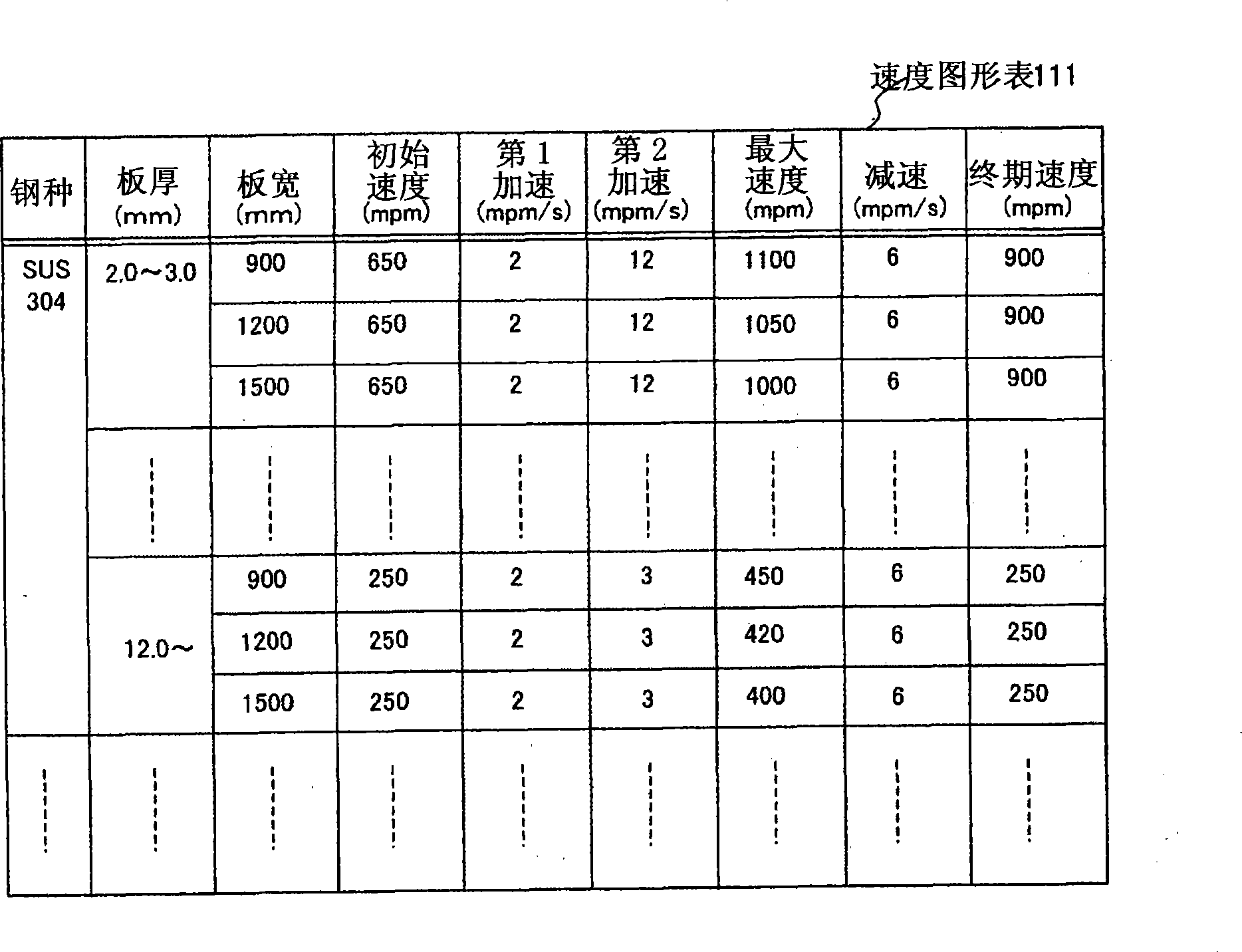

[0131] Next, an example in which the calender is a steckel mill will be described. Figure 17 The structure of the speed map table 111 corresponding to the steckel rolling is shown. With respect to the steel type, plate thickness, and plate width, the front end of the steel plate 151 is rolled out from the rolling machine 157, and the speed (initial speed) to be coiled on the downcoiler 154, and the constant speed after being rapidly accelerated ( Before the rear end of the steel plate 151 is rolled out from the rolling machine 157, it is rapidly decelerated, and the speed (final speed) before being coiled by the down coiler 154 is stratified.

[0132] The time interval determination unit 115 , calculation area determination unit 116 and control code calculation unit 117 determine the steel type, thickness and width of the steel coil, and extract the corresponding speed pattern from the speed pattern table 115 . For example, when the steel type is SUS304, the thickness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com