Honey peach storing method

A technology for peach and fruit, applied in the field of fruit storage, can solve problems such as unreported reports, and achieve the effects of maintaining good quality and commerciality, slowing down respiration rate, and slowing down fruit metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A method of the present invention: the fruit of 'Lakeview Honeydew' was collected in Zhejiang Province on July 25, 2007,

[0015] (1) Gently pick the ripe peach fruit together with the paper bag;

[0016] (2) Picking fruits in a room at 20°C for 3-5 hours, that is, pre-cooling, and picking fruits with uniform size, no mechanical damage, and no pests and diseases;

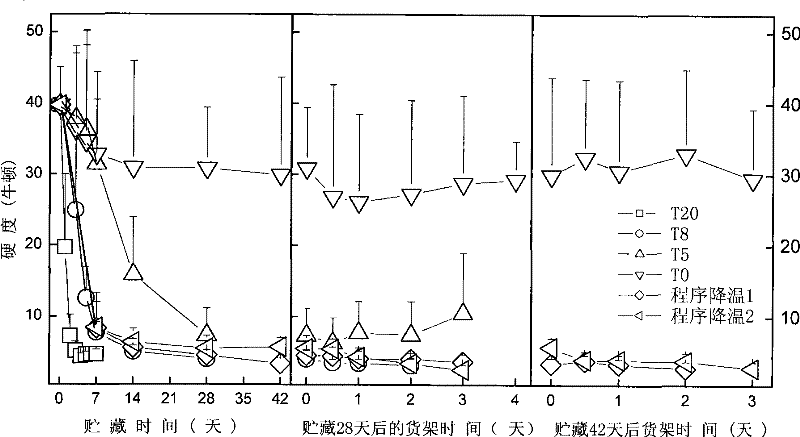

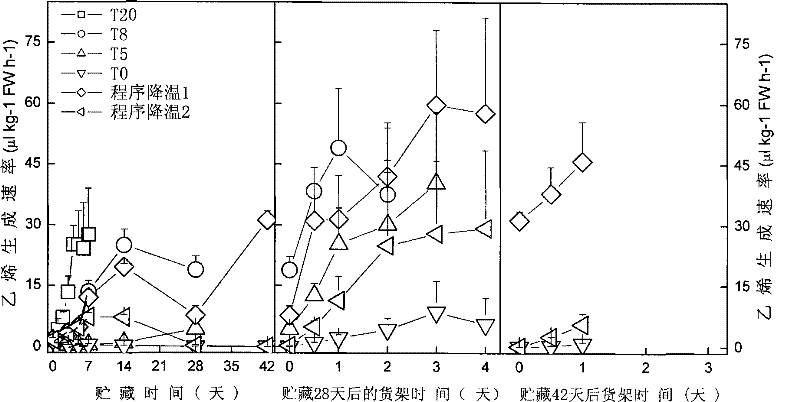

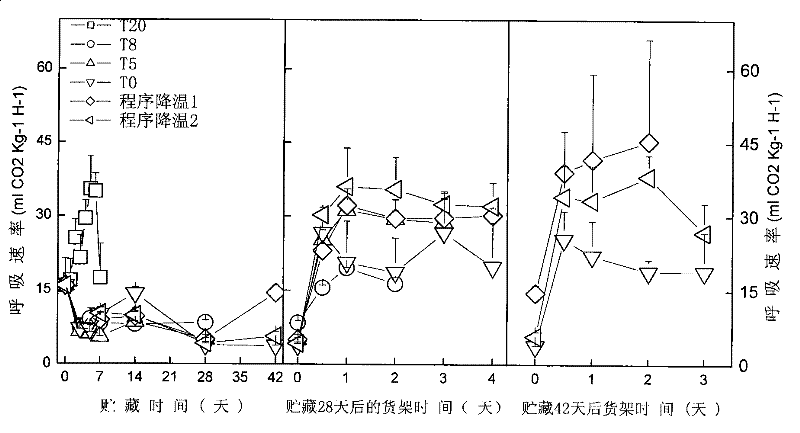

[0017] (3) Divide the picked fruits into 5 groups, the first group: placed directly at 0°C for low-temperature storage (T0); the second group: directly placed at 5°C for low-temperature storage (T5); the third group: directly placed at 5°C for low-temperature storage (T5); Low-temperature storage at 8°C (T8); the fourth group: low-temperature storage after the first program cooling treatment, that is, the fruit was stored at 8°C for 5 days at low temperature, and then the fruit was stored at 5°C at low temperature (program cooling 1) The fifth group: low-temperature storage after the second program cooling t...

Embodiment 2

[0026] According to the storage methods of five groups of different temperature treatments in Example 1, the experimental results of different temperature treatments on peach fruits were observed, and it was shown that among the five temperature treatments, compared with other treatment fruits, 0 ° C and programmed cooling 2 treatments can significantly reduce fruit rot , especially when the two treatments were stored until 28 days, no rotten fruit was found; at the same time, the results showed that the rot rate remained relatively low on the second day after 28 and 42 days, especially on the second day after storage for 28 days. The second day, the shelf rot rate was only 16%. The other three temperature treatments showed a relatively high rot rate, especially the rate of commercial fruit on the second day after the two treatments of T8 and T5 were transferred to the shelf after 28 days was already very low (Table 1).

[0027] Table 1 Effects of different temperature treatme...

Embodiment 3

[0030] An important indicator of the decline in quality of peach fruit during storage and transportation is the browning of the pulp due to aging or chilling damage. According to the storage methods of five groups of different temperatures in Example 1, the research results show that in the five treatments, no matter in the early storage The browning index of T0 and program cooling 2 is relatively low in the later stage of shelf transfer, but the study found that the browning index of peach fruit during storage at 0°C was significantly higher than that of program cooling 2, especially after the shelf. On the third day after storage for 28 days, the browning index of T0 treatment was more than 6 times that of programmed cooling 2. This may be due to the high degree of chilling injury during storage at 0°C, and the obvious characteristics of chilling injury after being transferred to the shelf, resulting in a decline in the quality and commerciality of the stored fruit (Table 2)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com