Thread moulding screw

一种攻螺纹、螺钉的技术,应用在攻螺纹的螺钉领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

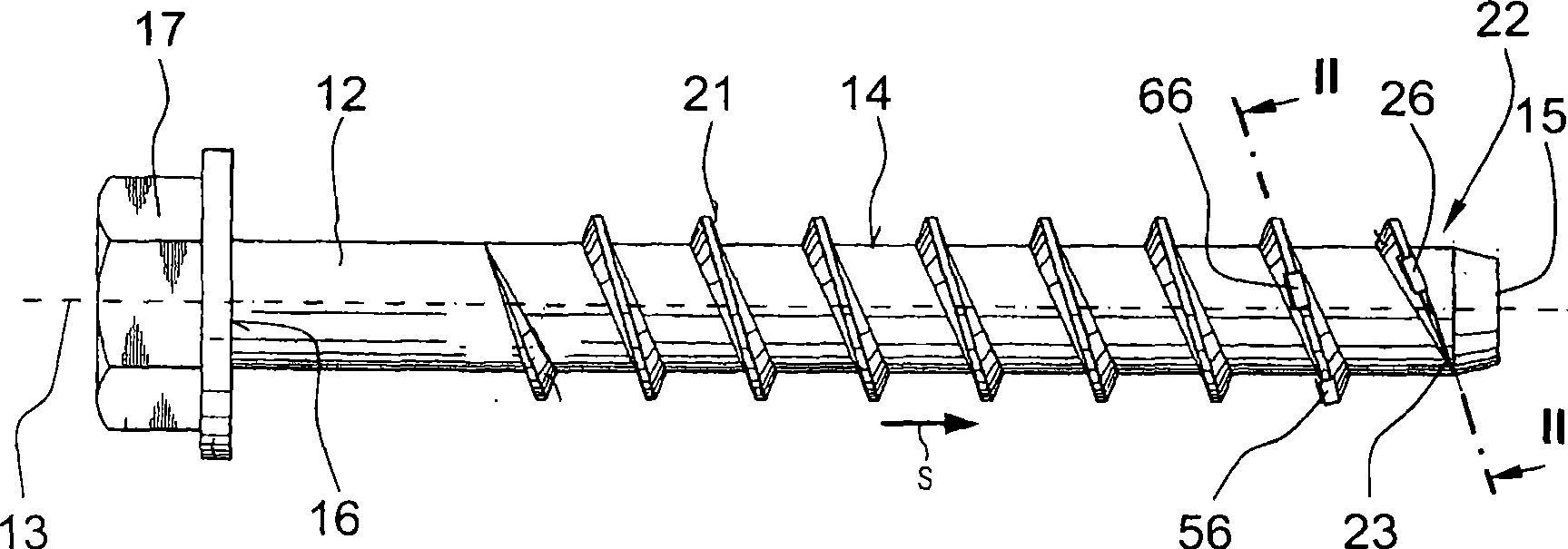

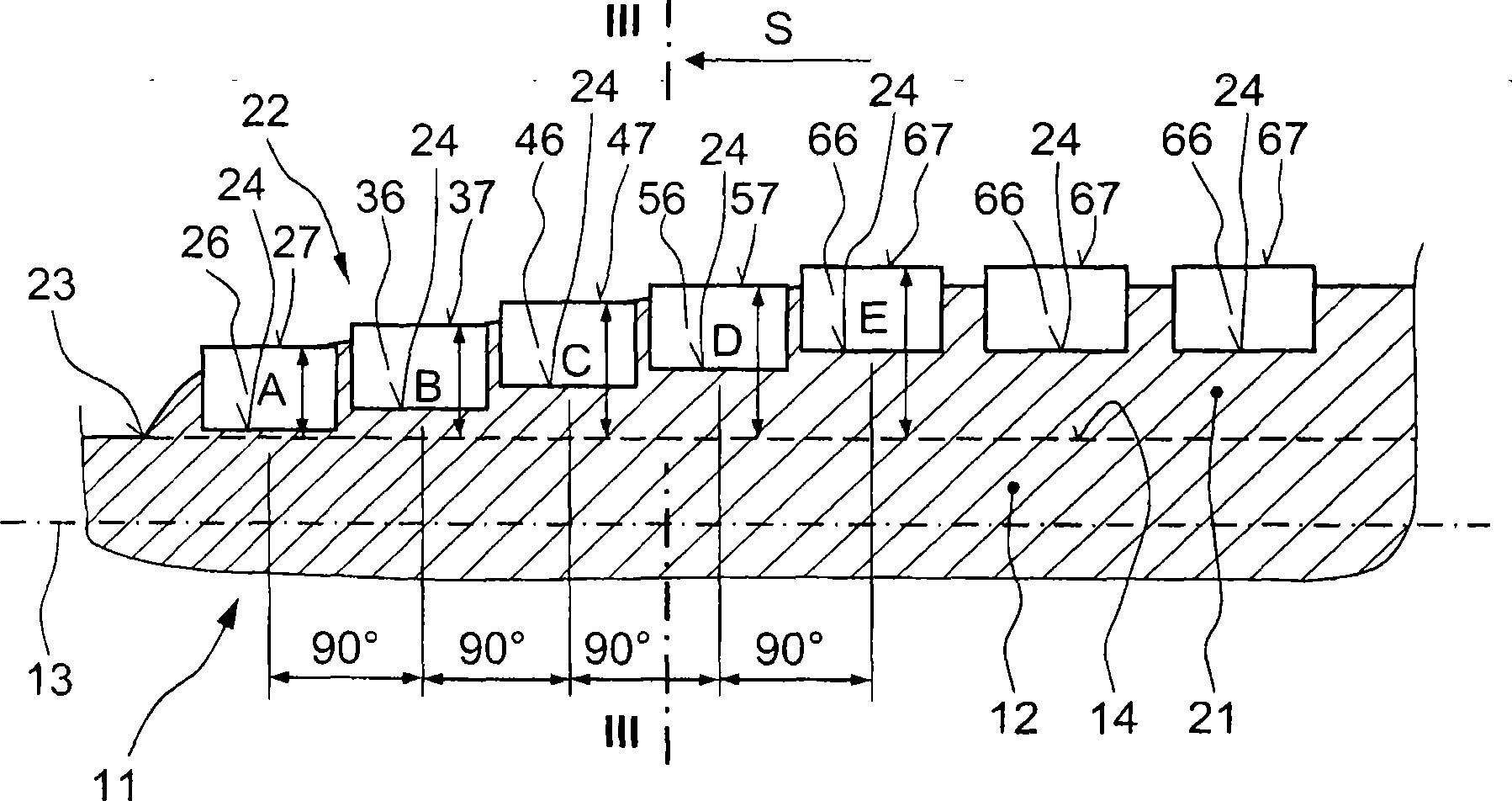

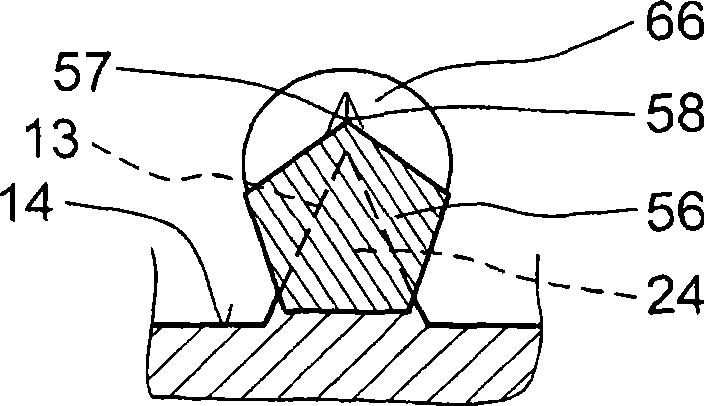

[0021] In principle, identical parts are provided with the same reference numerals in the figures.

[0022] exist figure 1 and 2 The tapped screw 11 shown in has a shank 12 with which a thread 21 integrally extends from a free end 15 of the shank over at least part of its length. The shank 12 extends along the longitudinal axis 13 of the screw 11 and has a radial shank outer side 14 . At the other end 16 opposite the free end 15, a hexagonal screw head is arranged as the rotationally active element 17. Arrow S in the figure correspondingly indicates the screwing direction of the screw 11 .

[0023] The thread 21 has cutting bodies 26 , 36 , 46 , 56 , 66 made of a harder material than the thread 21 in a radially outwardly opening recess 24 . The radially outer contours 27 , 37 , 47 , 57 , 67 of the cutting bodies 26 , 36 , 46 , 56 , 66 protrude at least partially beyond the thread 21 . The height of the thread 21 relative to the outside 14 of the shank decreases continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com