Method for manufacturing door and door made by the method

A manufacturing method and door frame technology, applied in door/window applications, separation methods, chemical instruments and methods, etc., can solve problems such as monotonous appearance, pollution of purification function core, non-replaceable door panels, etc., to achieve rich appearance varieties, Strong air purification effect, easy to replace the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

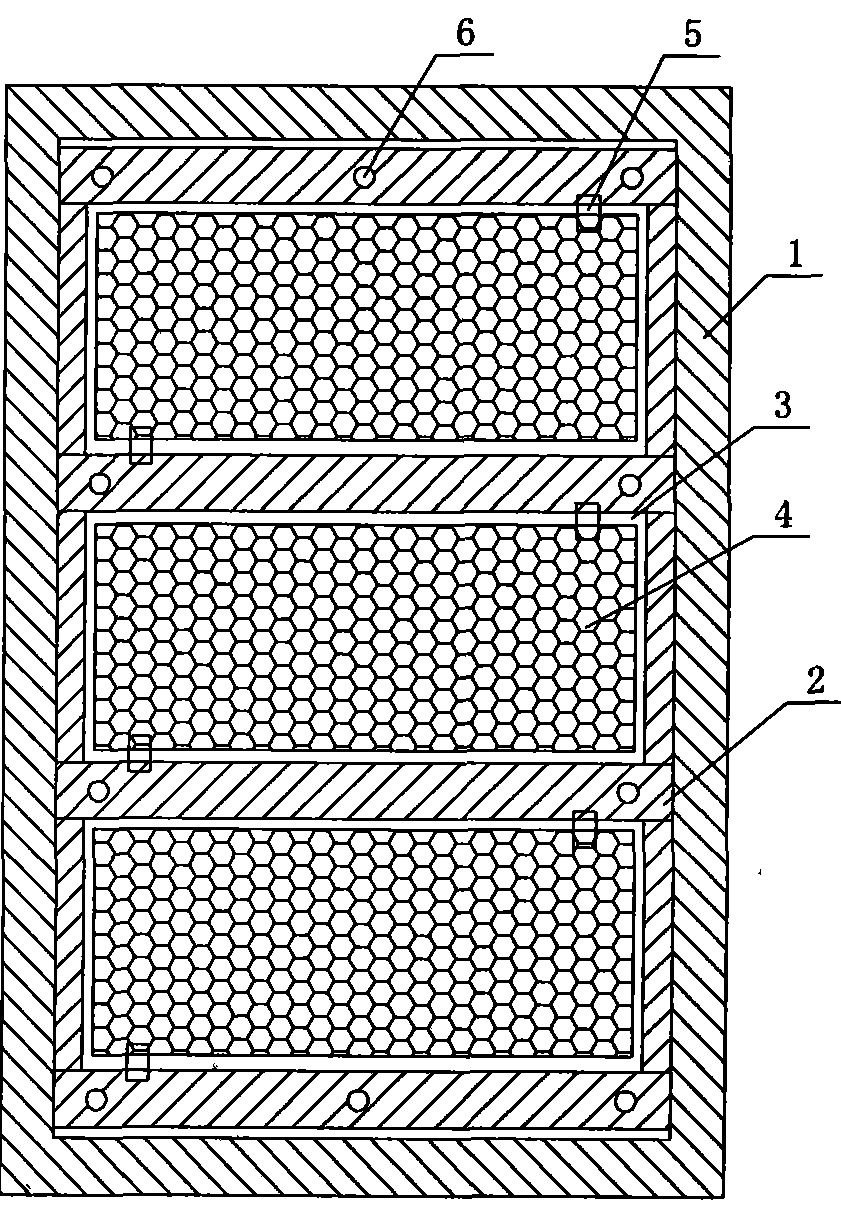

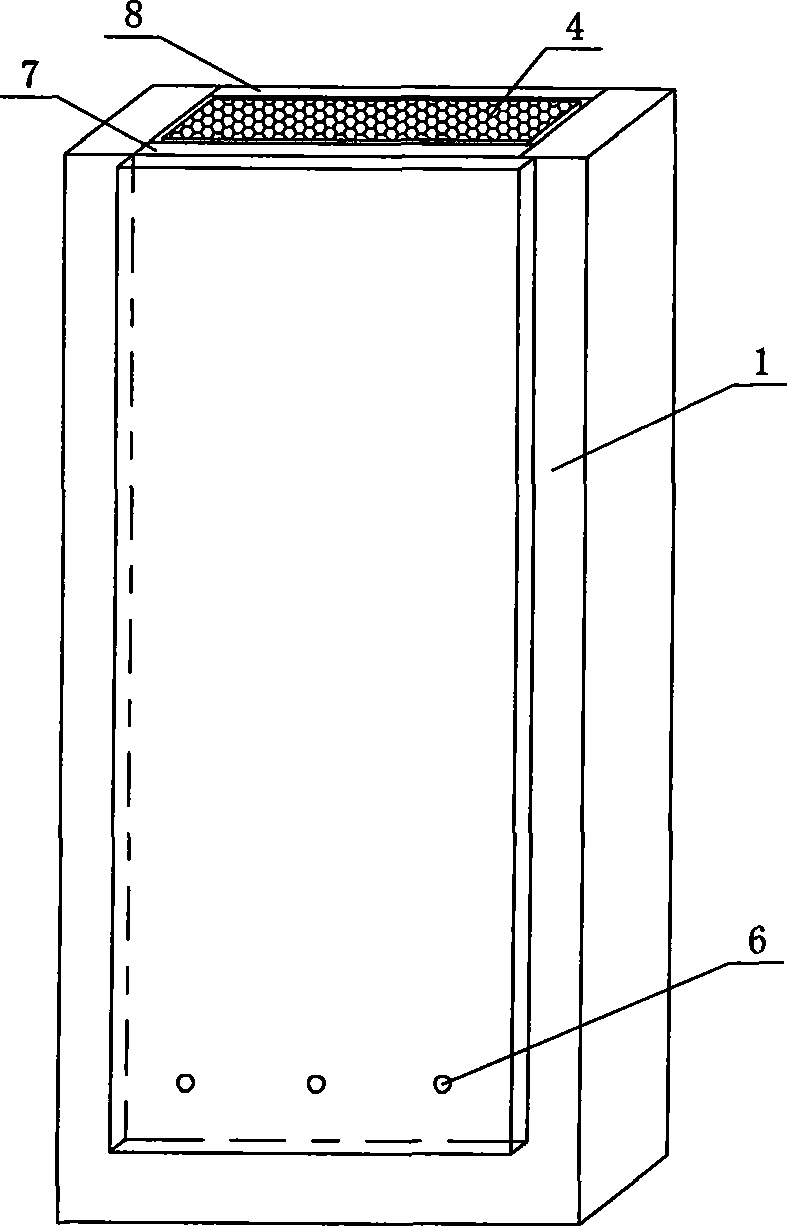

[0051] Refer to attached Figure 9 , the present embodiment is provided with a door of nano-modified bamboo charcoal. This embodiment also includes a door body. The main body of the door is composed of a door frame 1, a keel 2, and a fixed panel. The air purification function block 4 is installed in the inner cavity, and the opening of the inner cavity is detachably connected to the ventilation panel 7. In this embodiment, the air purification function block 4 The air-purifying functional material 42 is nano-modified bamboo charcoal, and the keel 2 is a hollow particleboard. The used connector 6 for fixing the air-permeable panel is a copper screw.

Embodiment 2

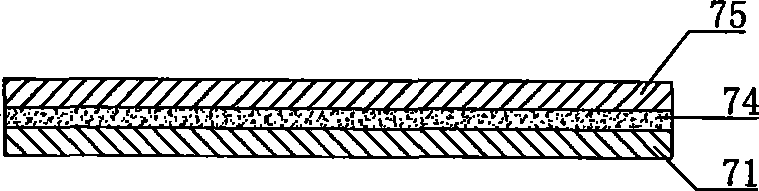

[0053] Refer to attached Figure 10 , 11 , the breathable panel of the present embodiment is a door of a sandwich panel. This embodiment also includes a door body, an air purification functional block and a ventilating panel. In this embodiment, the functional material 42 is nano-modified bamboo charcoal or bamboo charcoal, and the front panel is a sandwich ventilating panel. The air-permeable panel includes a front surface panel 71 and a bottom plate 75. The front surface panel 71 adopts a glass plate, the inside of the front surface panel 71 is provided with a picture layer 74, and the bottom plate 75 is a high-density fiberboard. 1 is the same. The used connector 6 for fixing the air-permeable panel is a stainless steel screw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com