Production process for extracting high-purity birutan from flos sophora

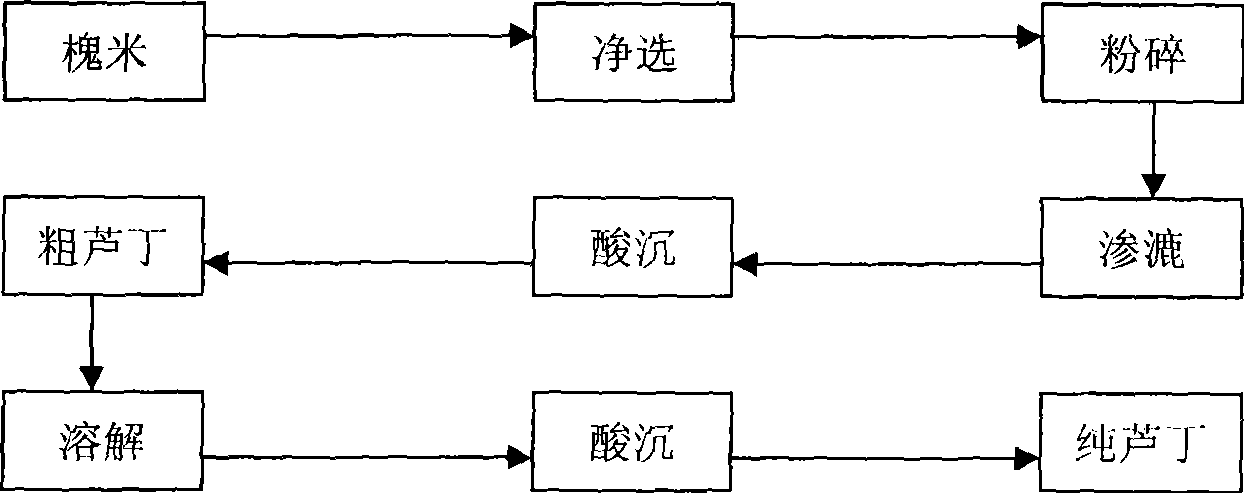

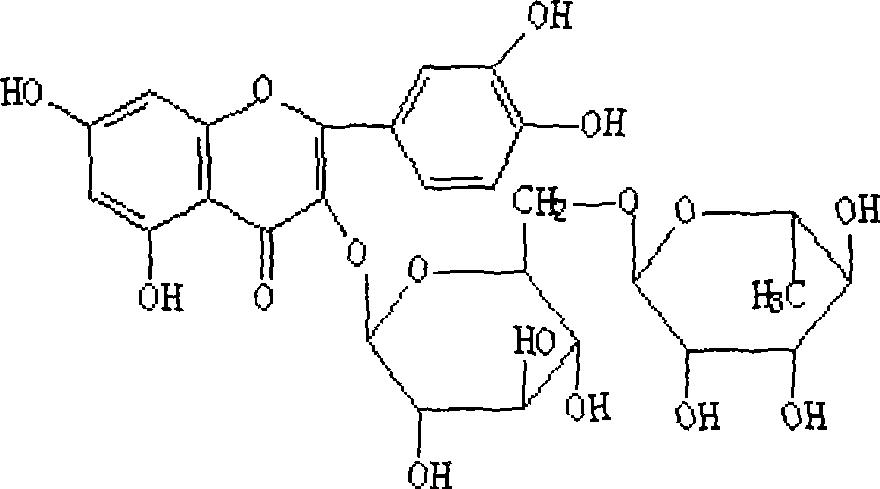

A technology of production process and extraction process, which is applied in the field of production process of extracting high-purity rutin from Sophora japonica, can solve the problems of low content, high production cost, and low yield, and achieve improved solubility, low extraction cost, and high yield. rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

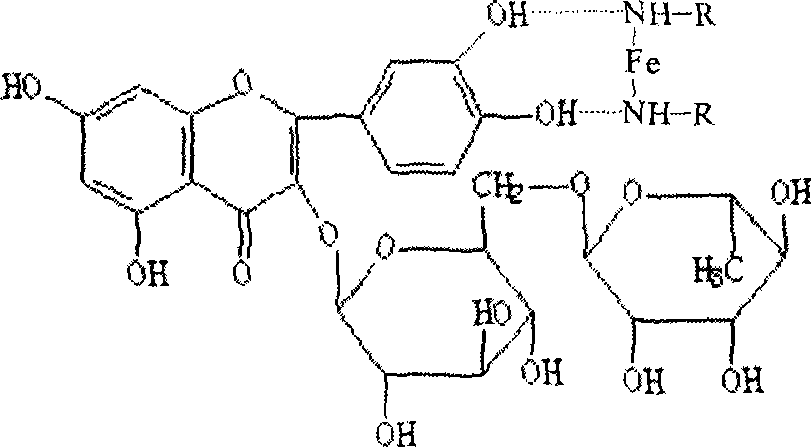

[0025] Take an appropriate amount of quicklime, add water to fully stir to make it saturated, let it stand, take 400ml of the upper clarified saturated lime aqueous solution, add 3g of borax, stir well, and keep it as a percolation solvent; In the percolation device, wet it with boiling water, place it for 5-10 minutes, add solvent for percolation, control the flow rate at about 12ml / min, collect the percolation liquid, adjust the pH of the percolation liquid to between 3 and 4 with hydrochloric acid, and place it After 12 hours, filter with suction, and wash the filter residue with purified water to neutrality to obtain crude rutin; add and dissolve the crude rutin into a saturated ferric ammonium citrate solution (the amount of the solution used is 20 times the amount of crude rutin) , then heated in a water bath at 40-50°C, and stirred continuously. After 30 minutes, filter, let cool, adjust the pH to 3-4, let stand for 24 hours, filter with suction, wash the filter residue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com