Shaft Single-rope hoisting drop-proof system

A single-rope lifting and anti-falling technology, applied in seat belts, life-saving equipment, etc., can solve the problems of difficulty in calling out the braking force, unstable cushioning performance, and cumbersome braking force adjustment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

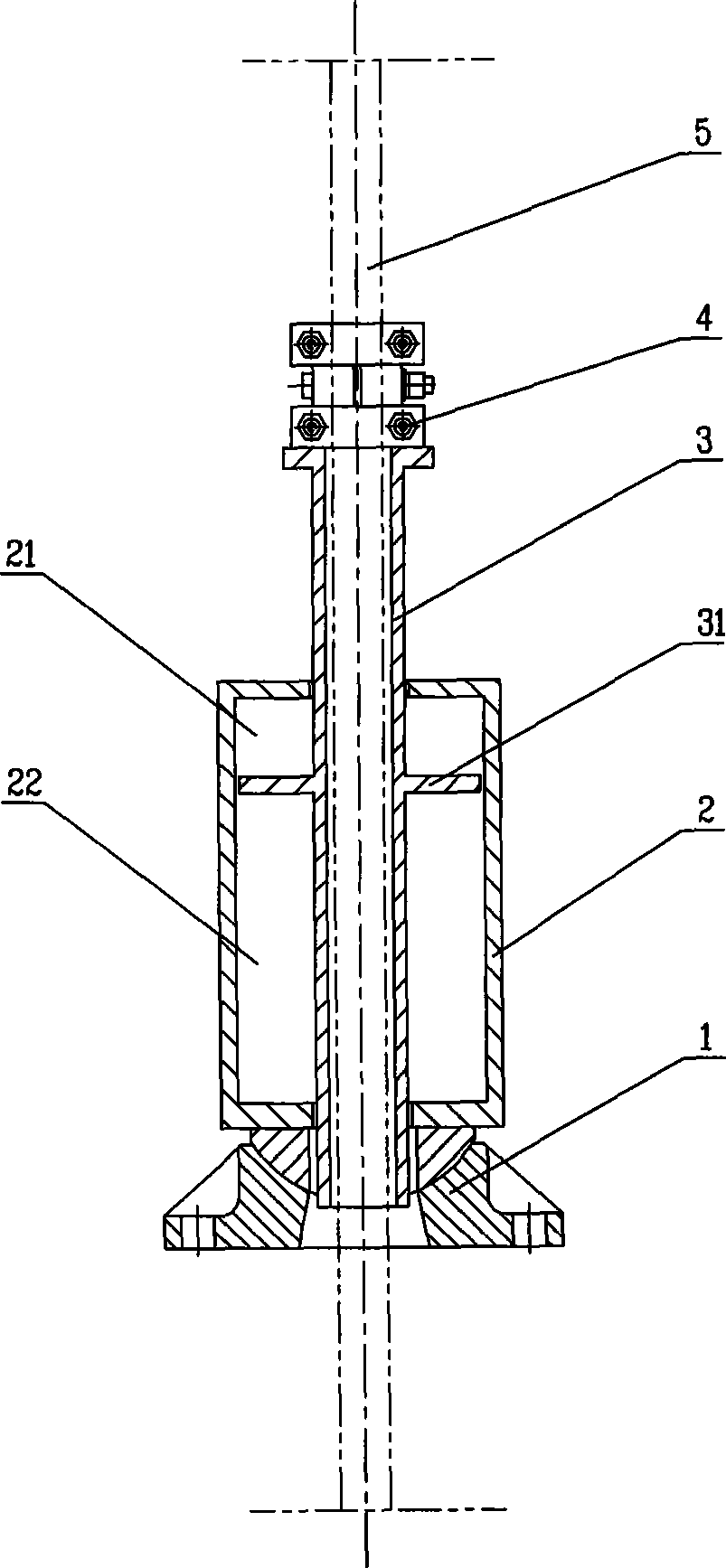

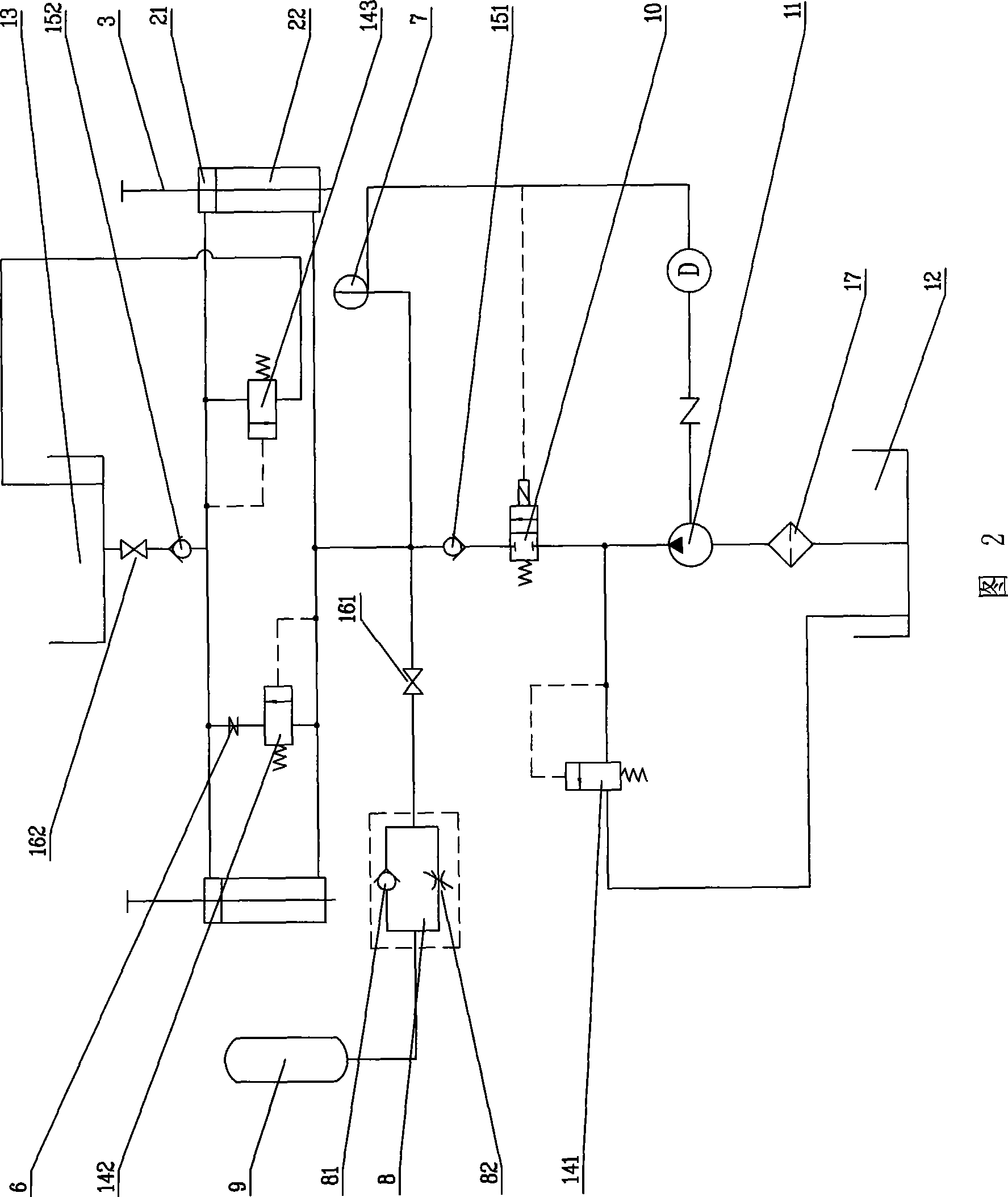

[0010] The invention relates to a single-rope hoisting anti-drop system for a shaft, which includes a brake wire rope and a hydraulic buffer, and the hydraulic buffer is composed of two hydraulic cylinders and a hydraulic circuit. see figure 1 As shown, it can be seen from the figure that the hydraulic cylinder includes a spherical bearing 1 , a cylinder body 2 , and a hollow piston rod 3 . The spherical support seat 1 is fixed on the well tower platform, the cylinder body 2 is fixed on the spherical support seat 1, the hollow piston rod 3 runs through the cylinder body 2 and the spherical support seat 1, and the upper end is fixed with a rope clamp 4, and the brake wire rope 5 After one end is fixed on the upper end of the hollow piston rod 3 by the rope clamp 4, it passes through the hollow part of the hollow piston rod 3, hangs at the bottom of the well and is tightened by the screw rod, and the hollow piston rod 3 has a cross bar 31 to connect the cylinder body 2 The inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com