Preparation method of inonotus obilquus as alpha-glucosidase inhibitors

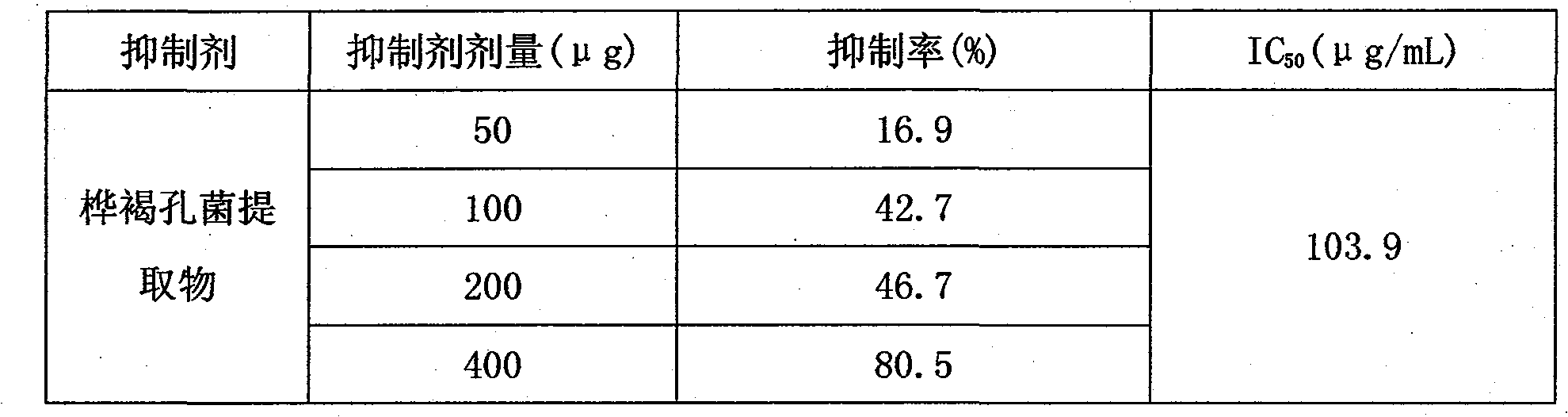

A technology for glucosidase and Inonotus obliquus, which is applied in the field of preparation of Inonotus obliquus extracts, can solve problems such as the extraction of α-glucosidase inhibitors that have not yet been found, and achieves strong inhibitory activity, simple process and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) After crushing 100g of Inonotus obliquus, pass through a 30-mesh sieve, then use 1000mL of 80% ethanol as an extraction solvent, heat and reflux at a temperature of 70°C for 3 times, each time for 1 hour, combine the extracts, and centrifuge Separate the supernatant, and obtain 16.2g ethanol extract after the supernatant is concentrated and dried;

[0018] (2) Disperse the above-mentioned ethanol extract in 324mL distilled water, then use 162mL petroleum ether to vibrate and extract 3 times for 2 hours each time, and separate the extract from the aqueous phase raffinate;

[0019] (3) The above aqueous phase raffinate was shaken and extracted with 162mL ethyl acetate for 3 times, each time for 2 hours, and then the extracts were combined, concentrated and dried to obtain 2.1g of α-glucosidase with strong inhibitory activity of tan powdered Inonotus obliquus extract.

Embodiment 2

[0021] (1) 100g of Inonotus obliquus is crushed and passed through a 30-mesh sieve, then 1200mL of 80% ethanol is used as an extraction solvent, heated and refluxed at a temperature of 75°C for 3 times, each time for 2 hours, the combined extracts are extracted, Filter, separate the supernatant, and obtain 18.1g ethanol extract after the supernatant is concentrated and dried;

[0022] (2) Disperse the above-mentioned ethanol extract in 543mL of distilled water, then shake and extract with 362mL petroleum ether for 4 times, each time for 2 hours, and separate the extract from the aqueous phase raffinate;

[0023] (3) The above-mentioned aqueous phase raffinate was extracted by shaking with 362mL ethyl acetate 4 times, each time for 2 hours, and then the extracts were combined, concentrated and dried to obtain 3.3g of α-glucosidase with strong inhibitory activity of tan powdered Inonotus obliquus extract.

Embodiment 3

[0025] (1) 100g of Inonotus obliquus is crushed and passed through a 30-mesh sieve, then 1200mL of 80% ethanol is used as an extraction solvent, heated and refluxed at a temperature of 75°C for 5 times, each time for 2 hours, the extracts are combined, and extracted Filter, separate the supernatant, and obtain 22.3g ethanol extract after the supernatant is concentrated and dried;

[0026] (2) Disperse the above-mentioned ethanol extract in 1115mL of distilled water, then use 669mL of petroleum ether to vibrate and extract 4 times, each time for 4 hours, and separate the extract from the aqueous phase raffinate;

[0027] (3) The above-mentioned aqueous phase raffinate was extracted by shaking with 669mL ethyl acetate 4 times, each time for 4 hours, and then the extracts were combined, concentrated and dried to obtain 4.0g of α-glucosidase with strong inhibitory activity of tan powdered Inonotus obliquus extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com