Power transmission chain made from metal

An energy guide chain, metal technology, applied in the field of energy guide chain, can solve the problems of environmental impact and limitation of the application of plastic energy guide chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

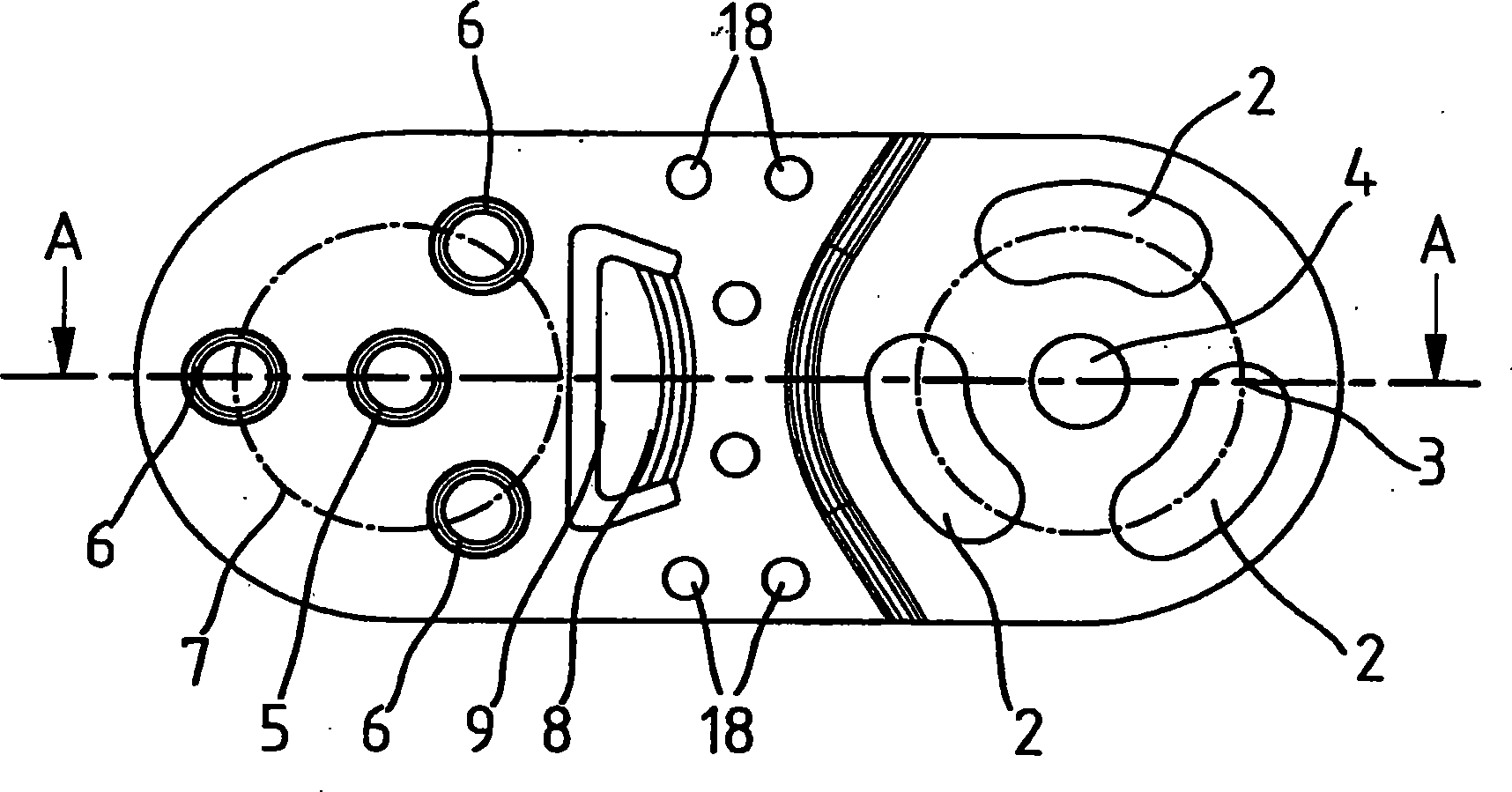

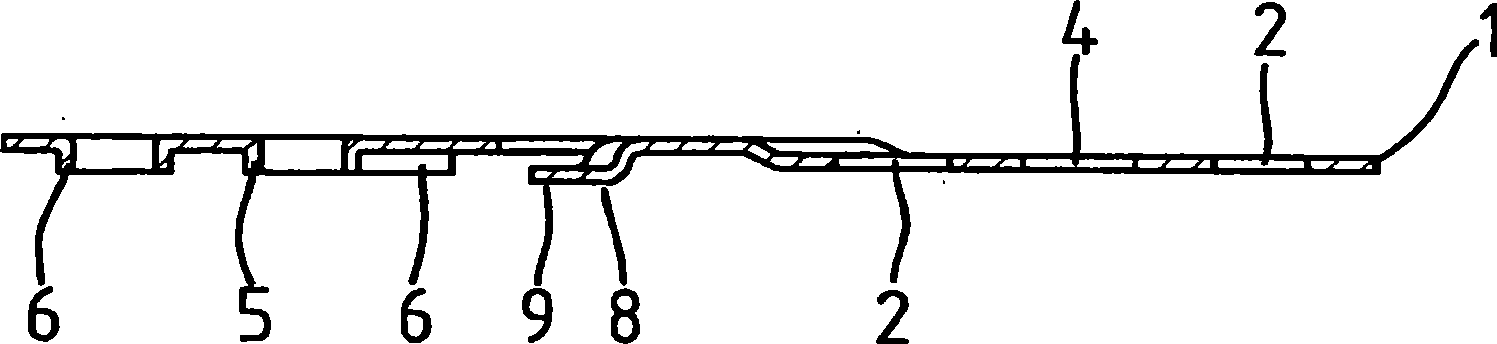

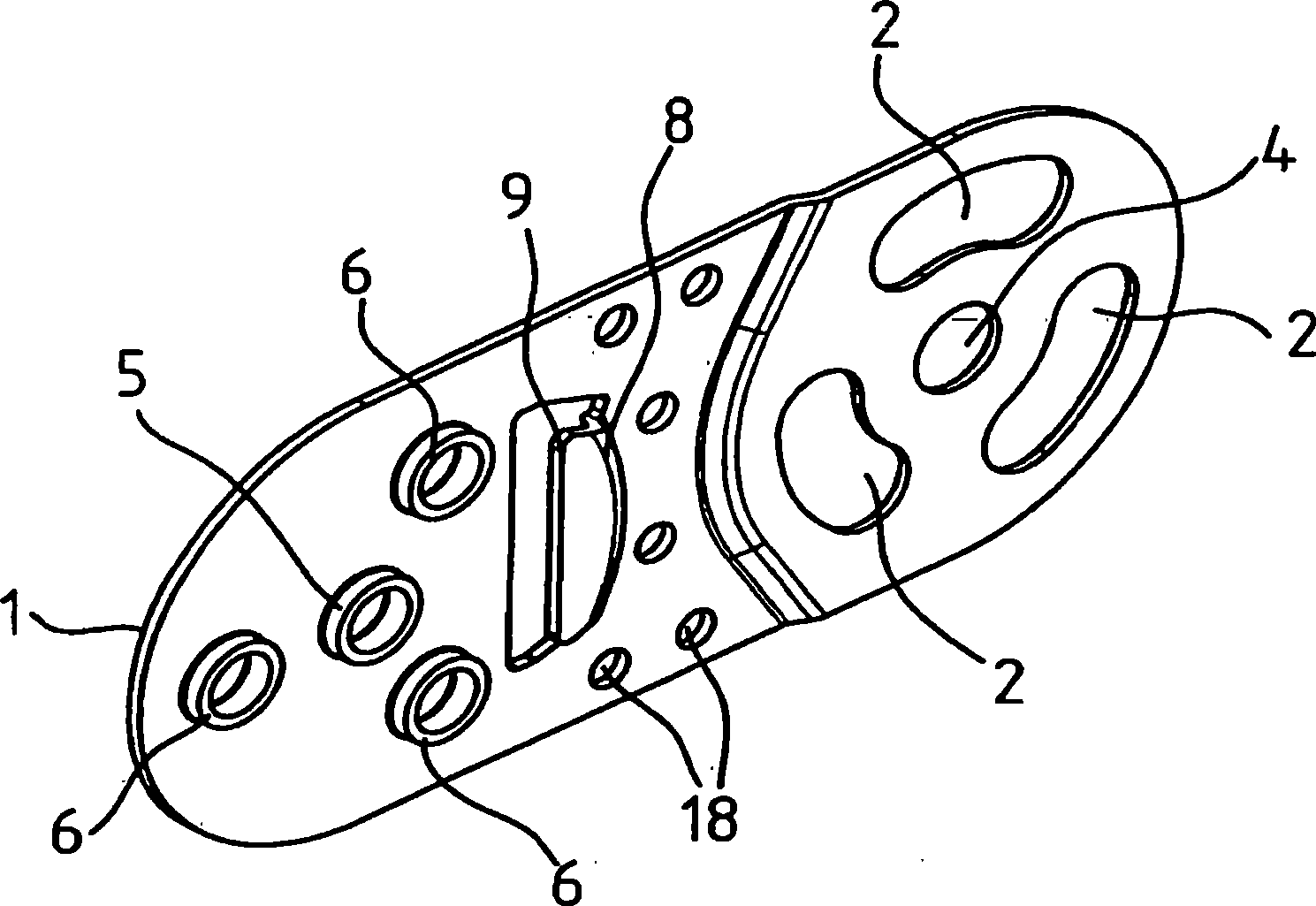

[0044] exist figure 1The chain plate for the energy-conducting chain link is shown in front view in . The link plate 1 consists of metal and has a first end region and a second end region. In the exemplary embodiment shown, the first end region has three through openings 2 . The through-holes 2 are designed as circular arcs, and they lie on a common imaginary circumference 3 . The through opening 2 surrounds a substantially circular through opening 4 which is substantially concentric to the imaginary circle 3 .

[0045] A plurality of elements 5 , 6 corresponding in number to the number of through-holes are formed on the opposite end regions, and these elements are inserted at least partially into corresponding through-holes of the other link plate when forming the energy-conducting chain. The element 5 is arranged centrally so that it can form, with the through-opening 4 , an articulated connection between two adjacent link plates. Elements 6 are arranged on an imaginary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com