A method for manufacturing an electronic assembly, electronic assembly, covering piece and substrate

A technology for electronic components and coverings, applied in the process of producing decorative surface effects, electrical components, and final product manufacturing, which can solve problems such as damage and achieve a stable and reliable support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] As previously described, like reference numerals designate like parts in the drawings.

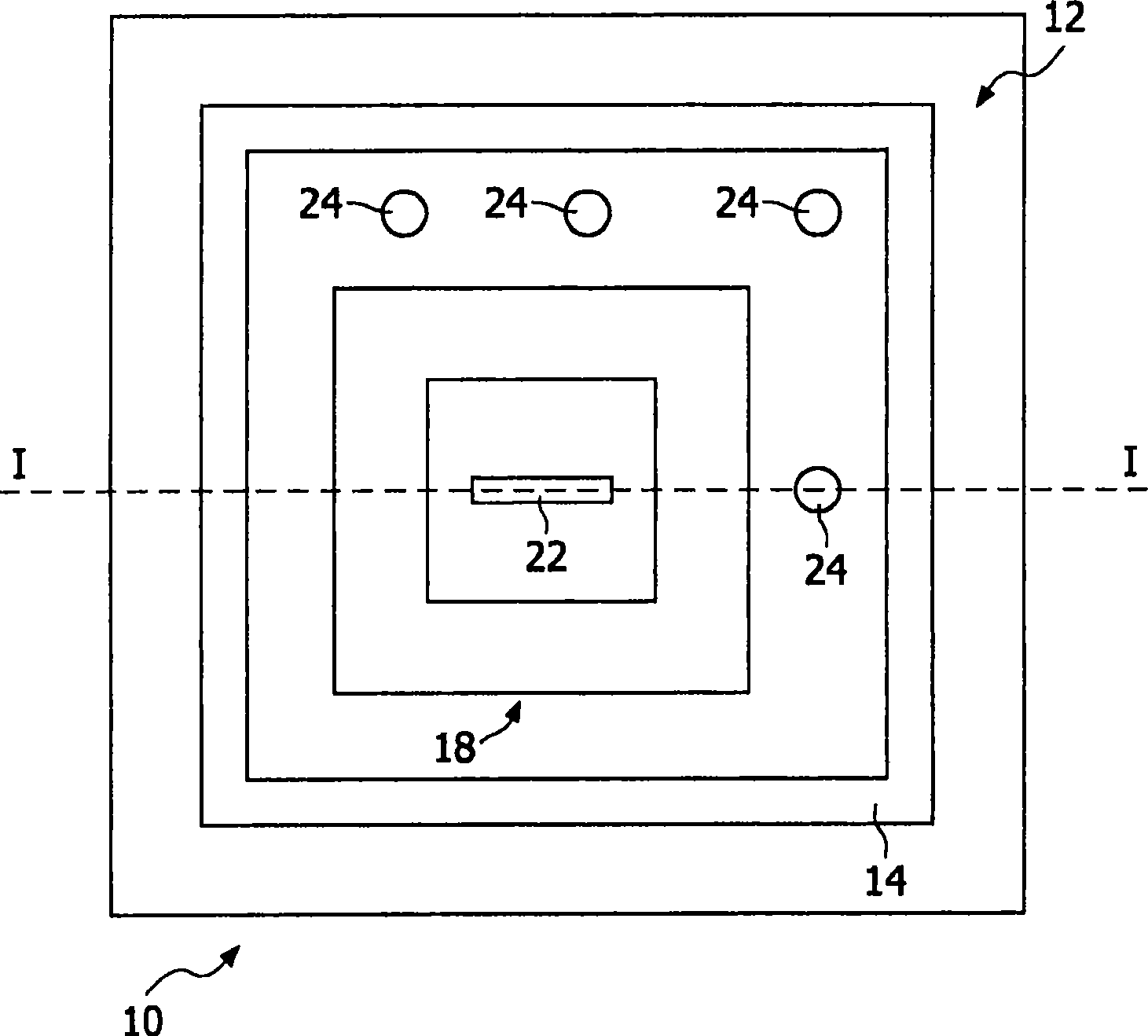

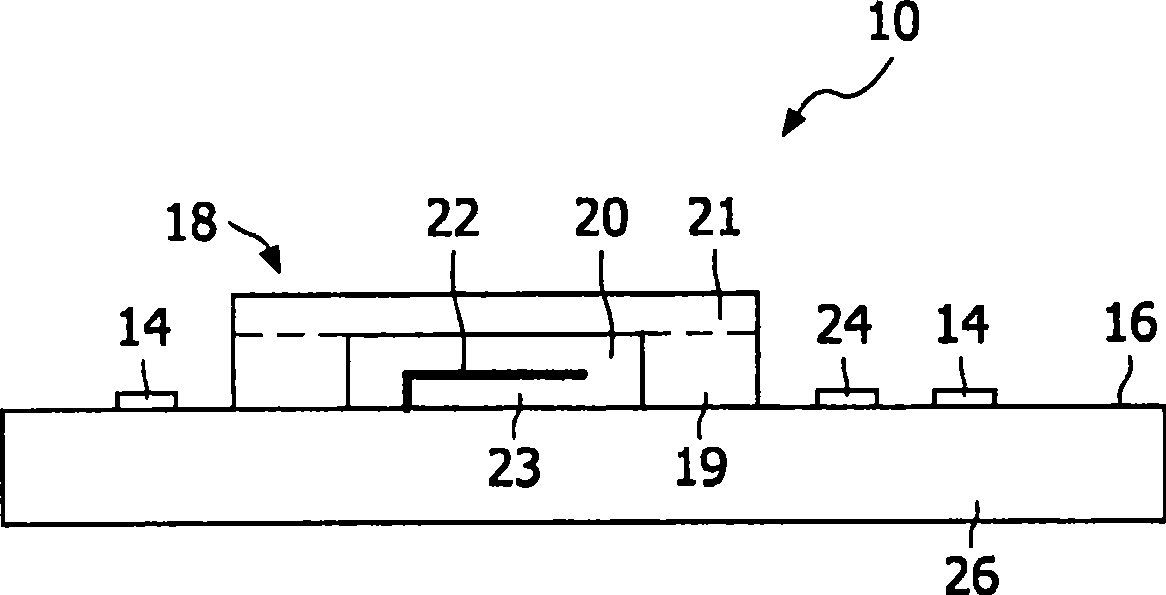

[0030] Referring now to FIGS. 1 a and 1 b , an electronic component 10 having a first pattern 12 of substantially closed structures 14 can be seen. A cover 18 is provided on the surface of the electronic component. The cover 18 together with the surface 16 defines a cavity 20 . Cavity 20 accommodates MEMS element 22 . The first pattern includes contact areas 24 electrically connected to electrical contacts of the electronic component (not shown).

[0031] As shown in FIGS. 1 a and 1 b , the closure structure 14 of the first pattern 12 seals the covering at the surface 16 . The closure structure 14 here has a rectangular shape. However, it may also have a circular, hexagonal or other suitable shape.

[0032] Preferably, the body 26 of the electronic component 10 comprises an integrated circuit, the solder pads of which are connected to the contact areas 24 . The MEMS element 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com