Method for detecting and manufacturing temperature measurement heating element and device

A technology of electric heating tube and electric heating alloy, which is applied in the direction of measuring device, adopting electric device, measuring heat, etc., which can solve the problems of increased resistance, error, and reduced heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

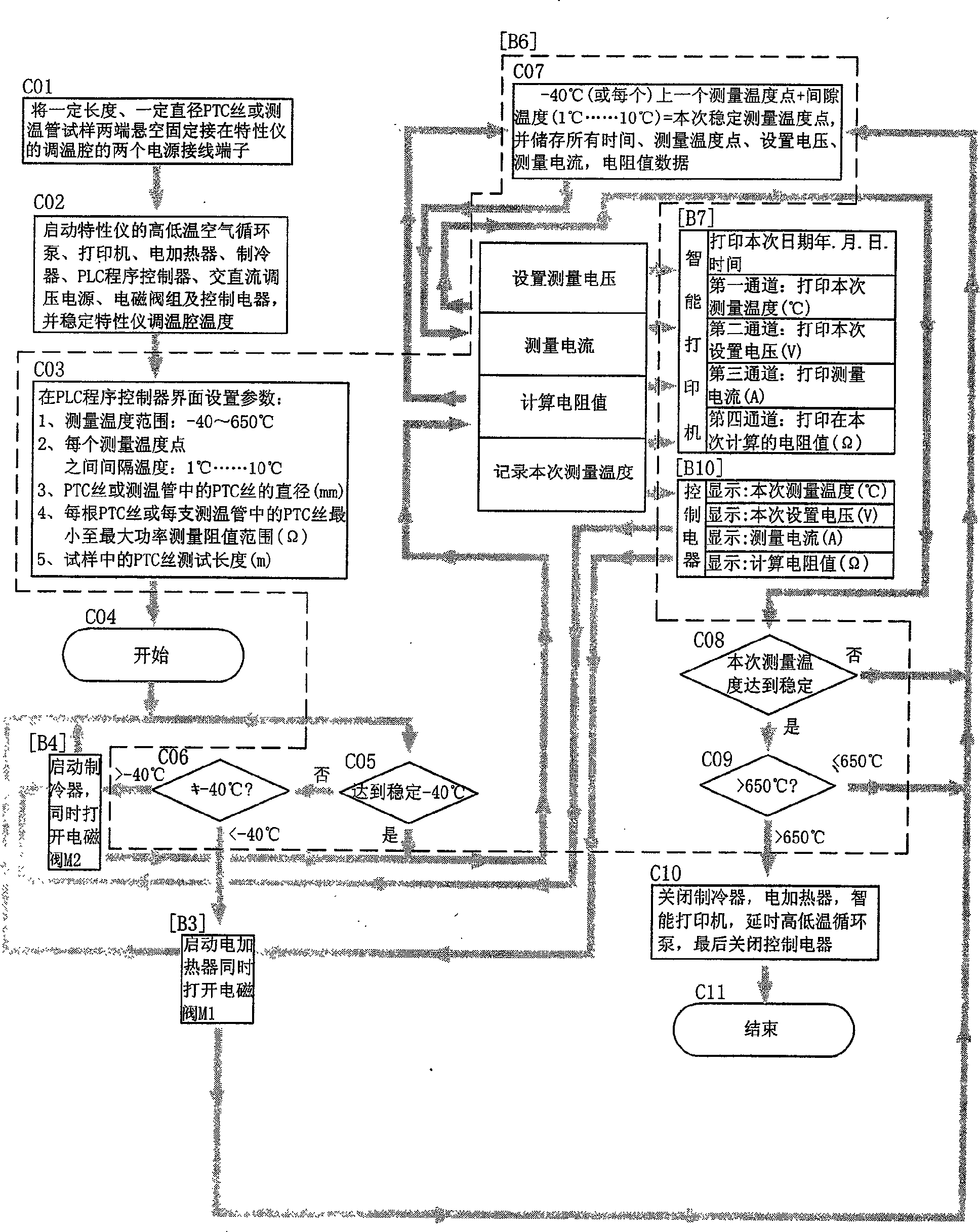

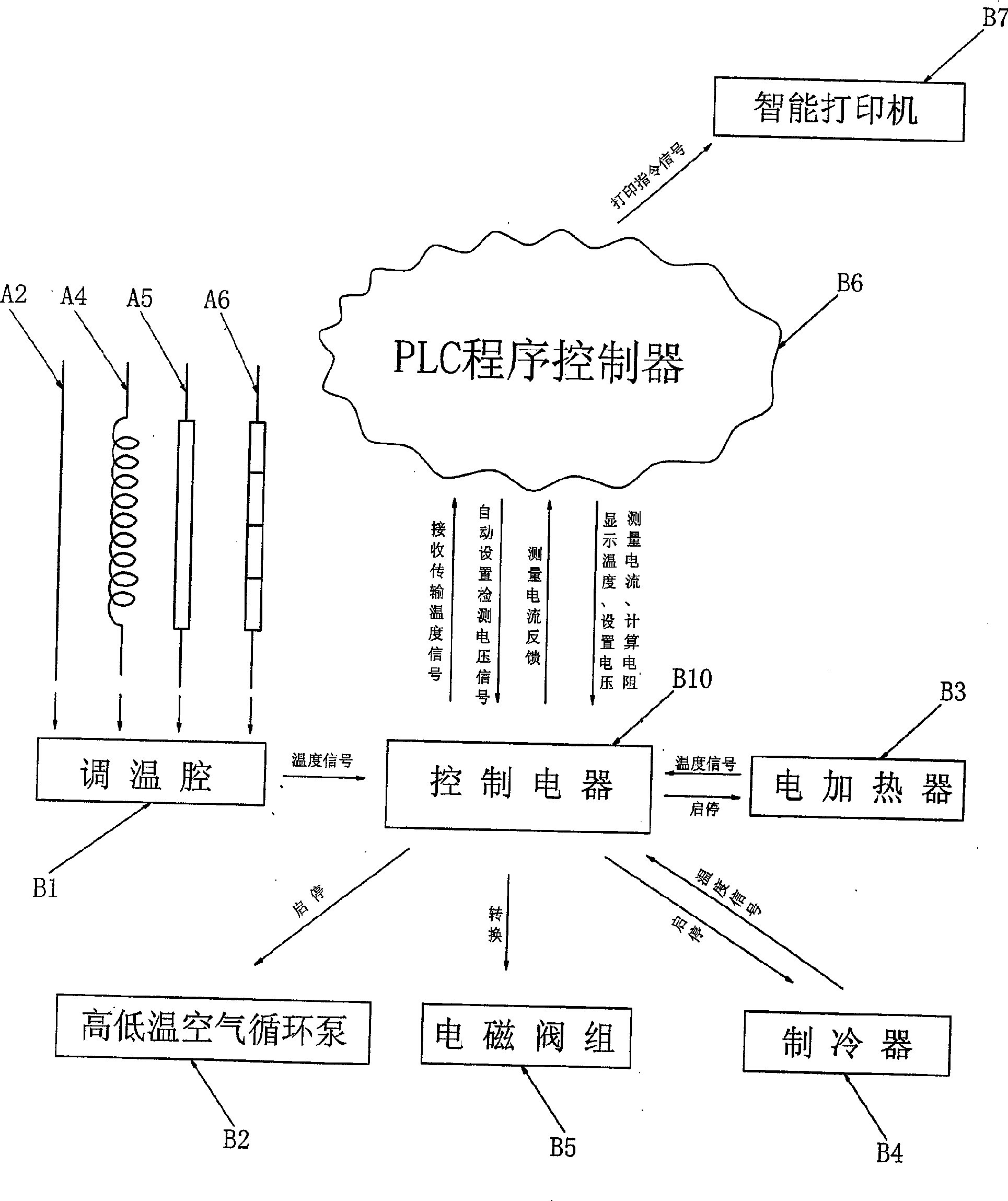

[0055] Specific implementation plan

[0056] The specific embodiments of the invention will be described in detail below with reference to the accompanying drawings.

[0057] 1. The function and use of the characterization instrument:

[0058] ① Solve the manufacturing, testing, and inspection of temperature measuring tubes, and provide guidance or processing to meet the manufacturing process necessary for testing accuracy;

[0059] ②To solve the change law between the "temperature-resistance" of PTC wire, use R=R 0 【1+α(T-T 0 )], 1 / ℃ is expressed by exponential law or other functions, or by instruments;

[0060] ③Understand the heating temperature of the electric heating tube and its inner spiral wire, and verify the correctness of the thermal theory with a characteristic meter to guide the temperature difference between the tube shell and the heating wire;

[0061] ④Use data to distinguish between "constant resistance" electric heating materials and PTC electric heating alloy ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com