Once tubular column process for combination oil production by multiple fracturing for oil gas well

A technology for layered fracturing and oil and gas wells, applied in the direction of drilling pipes, casings, production fluids, etc., can solve the problems of intensified conflicts between layers, difficulty in achieving fracturing effects, etc., achieve low operational risks, increase production and production effects , The effect of shortening the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

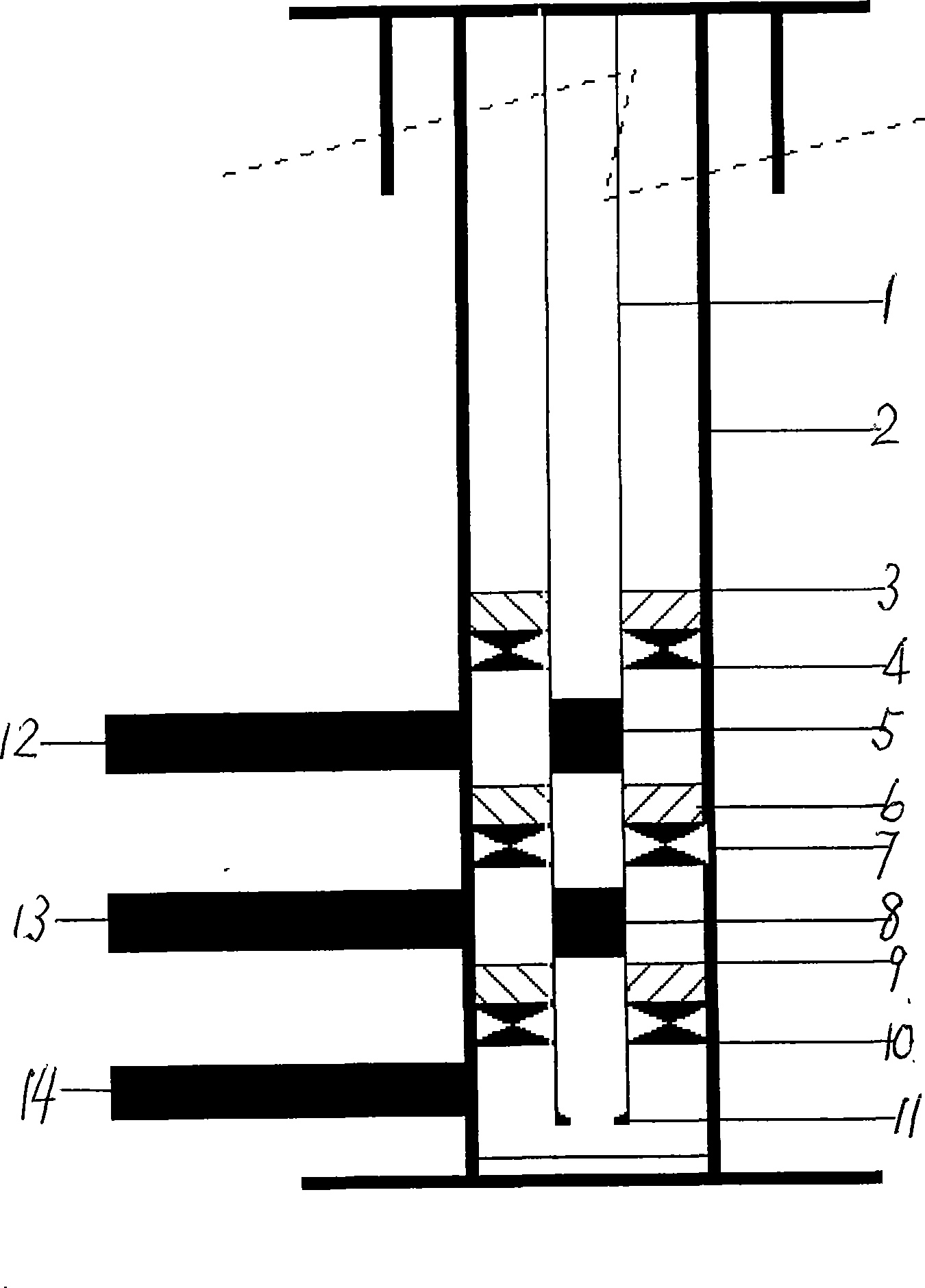

[0010] The implementation of the present invention will be described below in conjunction with the accompanying drawings.

[0011] As shown in the figure, the oil and gas well layered fracturing combined production process string given in this embodiment has three sets of formations. Hydraulic anchors 3, 6, 9 and packers 4, 7, 10 are respectively assembled on the pipe string above the corresponding parts of the three layers, and sliding sleeves 5 are respectively installed at the parts corresponding to the first and second layers. , 8, a ball seat 11 is provided at the lower end of the pipe string. In the figure, the subject matter represented by each label is as follows:

[0012] 1- oil pipe; 2- casing; 3, 6, 9- hydraulic anchor; 4, 7, 10- separator; 5, 8- sliding sleeve; 11- ball seat; 12, 13, 14- oil layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com