Support member for laminated glass and method for making same

A technology of laminated glass and supporting parts, which is applied in glass manufacturing equipment, glass forming, glass rolling, etc. It can solve the problems of difficult operation, easy aging, and affecting application performance, so as to achieve broad application prospects and improve heat insulation performance , Expand the effect of product varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

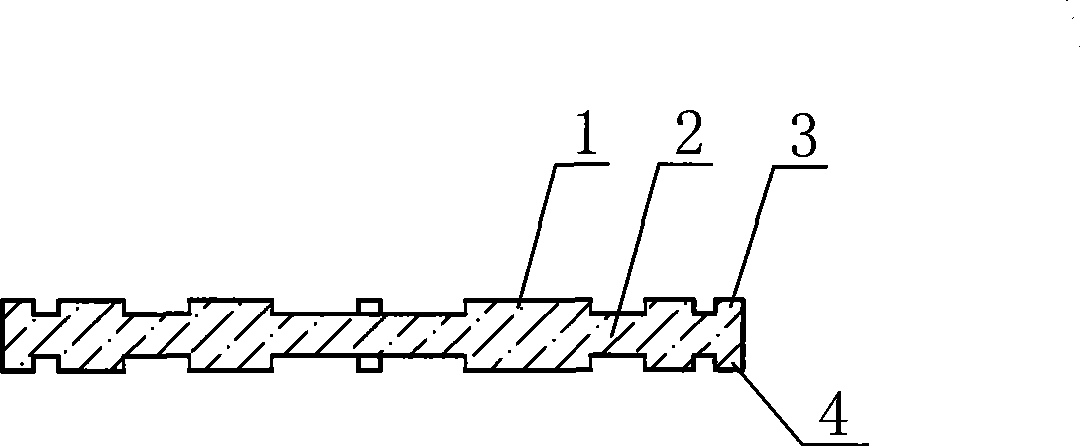

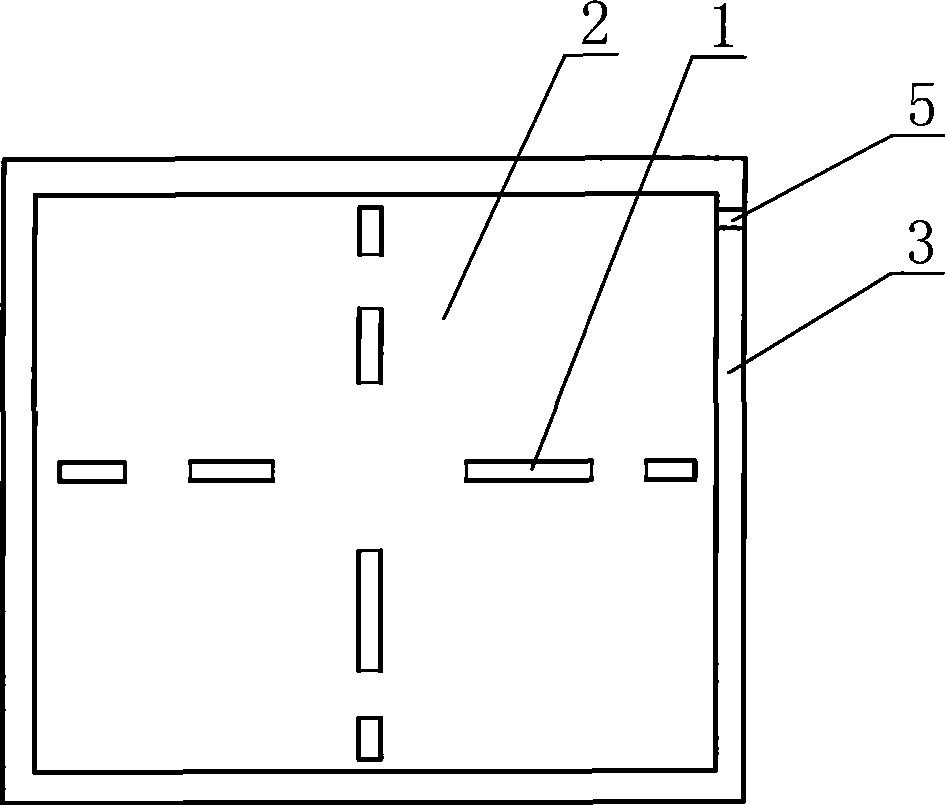

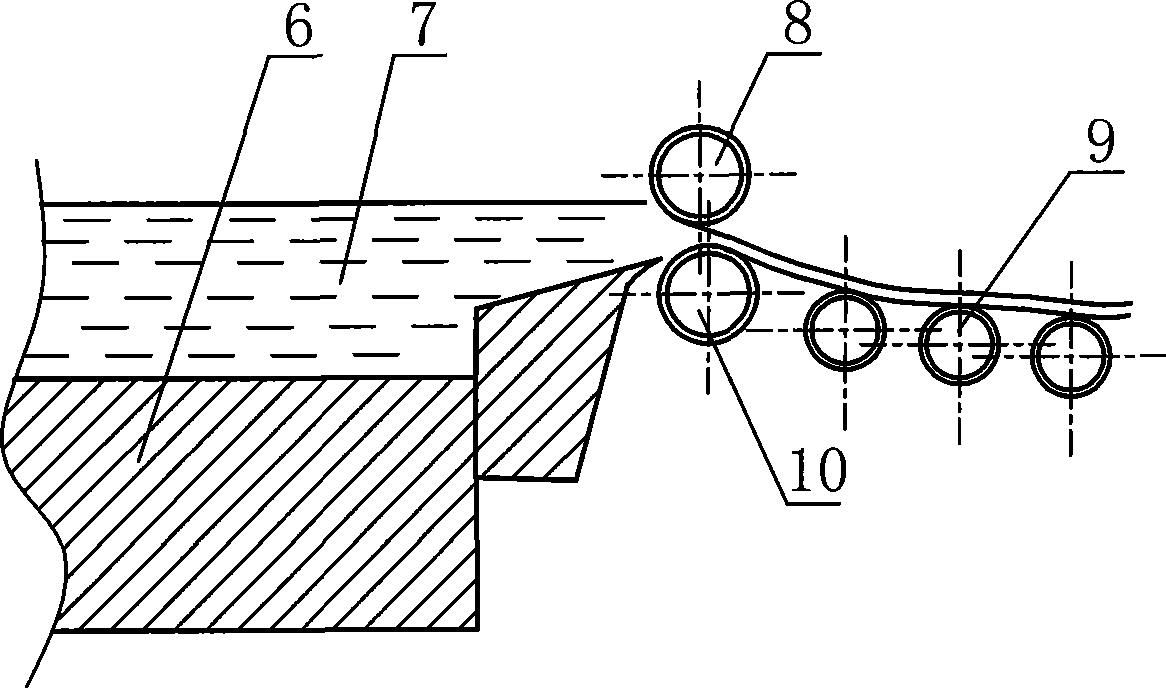

[0025] like figure 1 , figure 2 As shown, the laminated glass support of the present invention is a plate-shaped glass support 2, the periphery of which is adapted to the periphery of the laminated glass, and the upper and lower sides of the periphery are respectively provided with upper and lower support bosses 3, 4, and the upper support boss The platform 3 is provided with a ventilation slot 5, and the height of the upper support boss 3 is equal, that is, the same height. The heights of the upper and lower support bosses 3 and 4 on the upper and lower sides can be equal or different. There is a protrusion 1 integrated with it, and the height of the protrusion 1 is equal to the height of the upper support boss 3 to form a comprehensive support. The protrusions 1 can be distributed in a pattern, such as a cross in the figure, or can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com