Pollen beverage and preparation method thereof

A technology for bee pollen and honey, applied in the field of food and beverages, can solve the problems of inability to obtain bee pollen beverages, loss of pollen nutrients, complicated processes, etc., and achieves the effects of solving the loss of nutrients, easy rancidity and flocculent precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

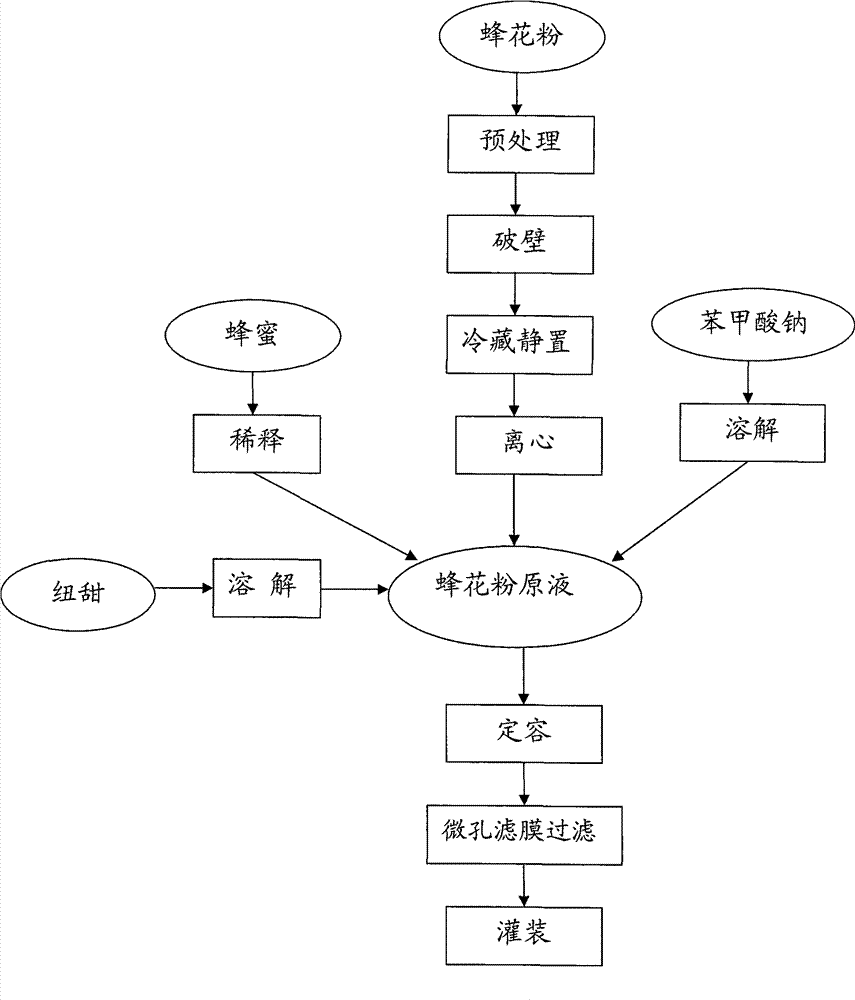

Method used

Image

Examples

Embodiment 1

[0025] (a) Pretreatment of bee pollen: collect bee pollen, remove black spots, silt and other sundries in bee pollen, dry in a drying oven at 45°C, weigh, pack, and refrigerate at -15°C for 48 hours.

[0026] (b) Wall breaking: select an appropriate amount of refrigerated bee pollen 50g, pour it into 100g of purified water at a temperature of 50°C, stir and dissolve it rapidly, mix the bee pollen solution, and grind it in a colloid mill to make the nutrients in the bee pollen Maximize the dissolution of the substance while removing the rising foam.

[0027] (c) Refrigerate and stand still: seal the broken bee pollen solution, refrigerate and stand at a low temperature of 4°C for 12 hours, use the siphon method to absorb the upper clear liquid, remove a large amount of solids, the solution is basically clear, and set aside.

[0028] (d) Centrifugation: centrifuge the supernatant at a speed of 1200r / min for 20min, remove suspended matter, and obtain a bee pollen stock solution. ...

Embodiment 2

[0034] (a) Pretreatment of bee pollen: collect 30 g of bee pollen, remove black spots, sediment and other sundries in the bee pollen, dry in a drying oven at 40°C, weigh, pack, and refrigerate at -25°C for 24 hours.

[0035] (b) Wall breaking: Pour 25g of refrigerated bee pollen into 100g of purified water at a temperature of 60°C, stir rapidly to dissolve, mix the bee pollen solution, and grind it in a colloid mill to maximize the nutrients in the bee pollen Maximize dissolution while removing floating foam.

[0036] (c) Refrigerate and stand still: seal the broken bee pollen solution, refrigerate and stand at a low temperature of 2°C for 20 hours, use the siphon method to absorb the upper clear liquid, remove a large amount of solids, the solution is basically clear, and set aside.

[0037] (d) Centrifugation: centrifuge the supernatant at a speed of 1000 r / min for 25 minutes, remove suspended matter, and obtain a bee pollen stock solution.

[0038] (e) Add honey diluent: t...

Embodiment 3

[0044] (a) Pretreatment of bee pollen: Take 40g of bee pollen, remove black spots, sediment and other sundries in the bee pollen, dry in a drying oven at a low temperature of 50°C, weigh, pack, and refrigerate at -20°C for 36h.

[0045] (b) Wall breaking: Pour 35g of refrigerated bee pollen into 105g of purified water at a temperature of 55°C, stir rapidly to dissolve, mix the bee pollen solution, and grind it in a colloid mill to maximize the nutrients in the bee pollen Maximize dissolution while removing floating foam.

[0046] (c) Refrigerate and stand still: seal the broken bee pollen solution, refrigerate and stand at a low temperature of 8°C for 24 hours, use the siphon method to absorb the upper clear liquid, remove a large amount of solids, the solution is basically clear, and set aside.

[0047] (d) Centrifugation: centrifuge the supernatant, centrifuge at 900r / min for 30min, remove suspended matter, and obtain the bee pollen stock solution.

[0048] (e) Add honey di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com