Portable electric tea-leaf picking device

A tea picking machine, electric technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve problems such as difficulty in starting, incomplete collection of tea leaves, increased friction, etc. , the effect of easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below with reference to accompanying drawing, and in conjunction with specific embodiment, the present invention is described in further detail:

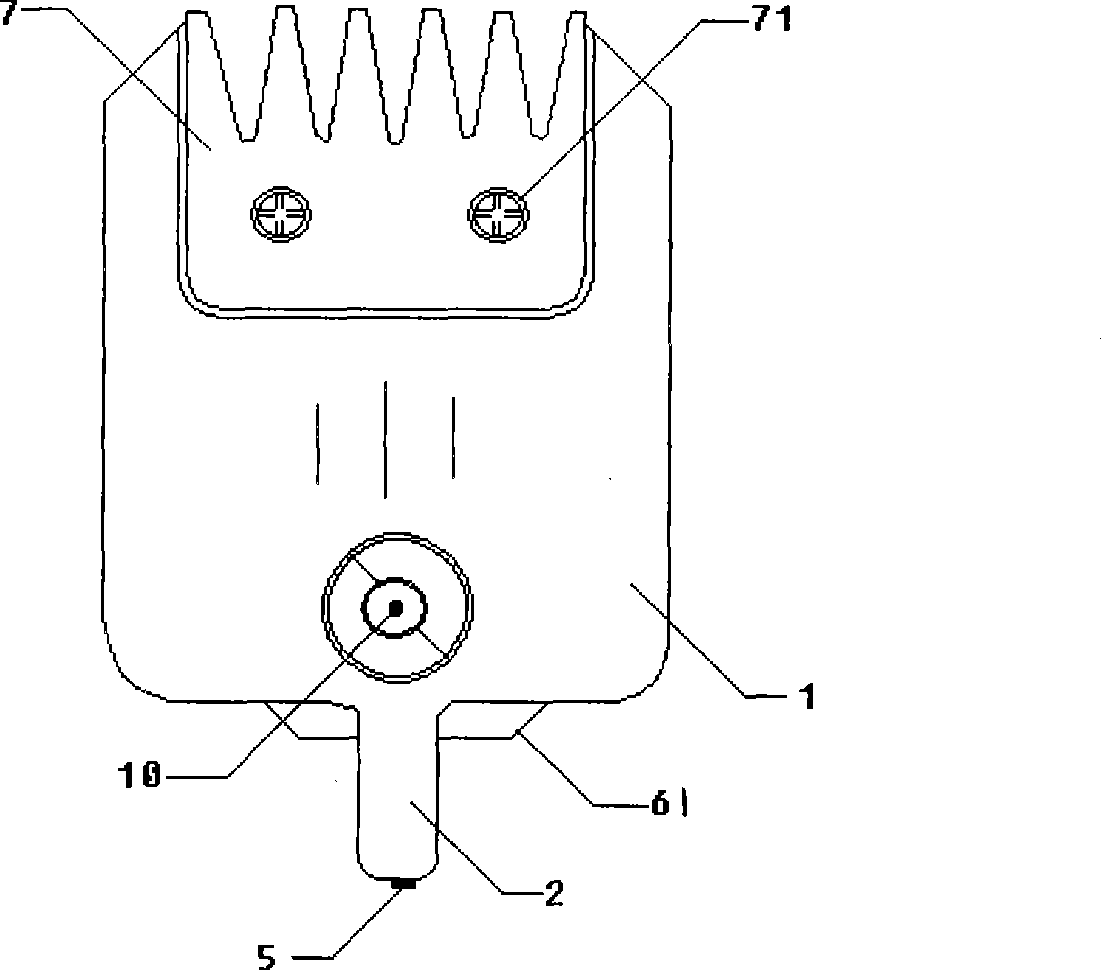

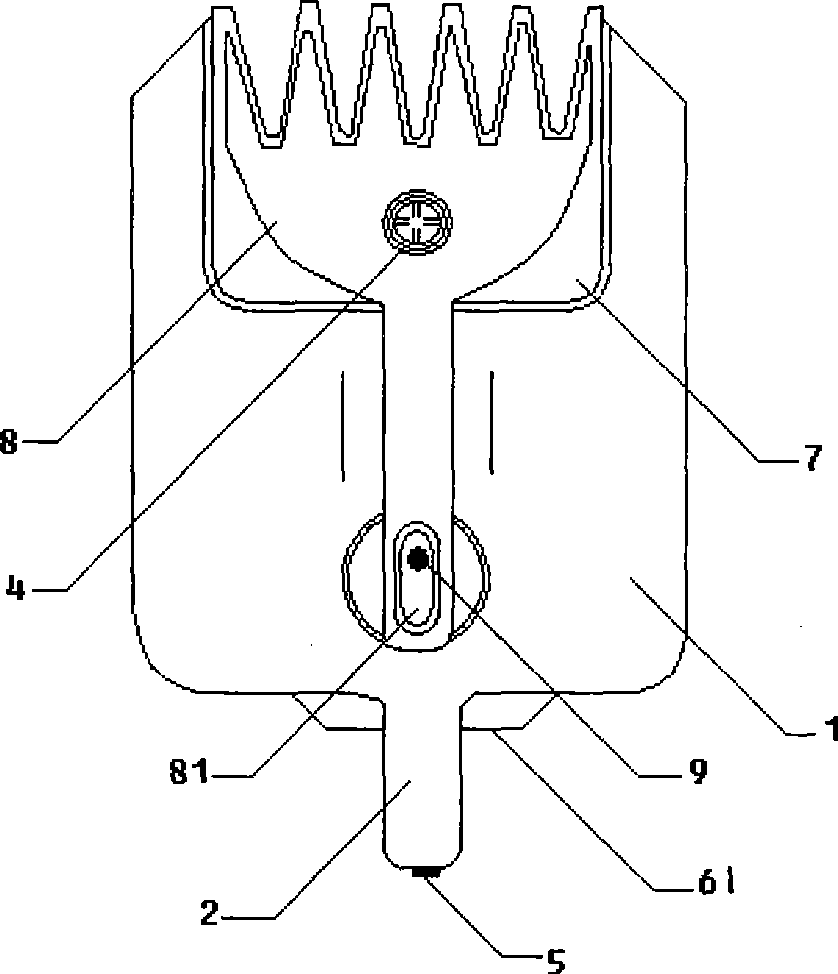

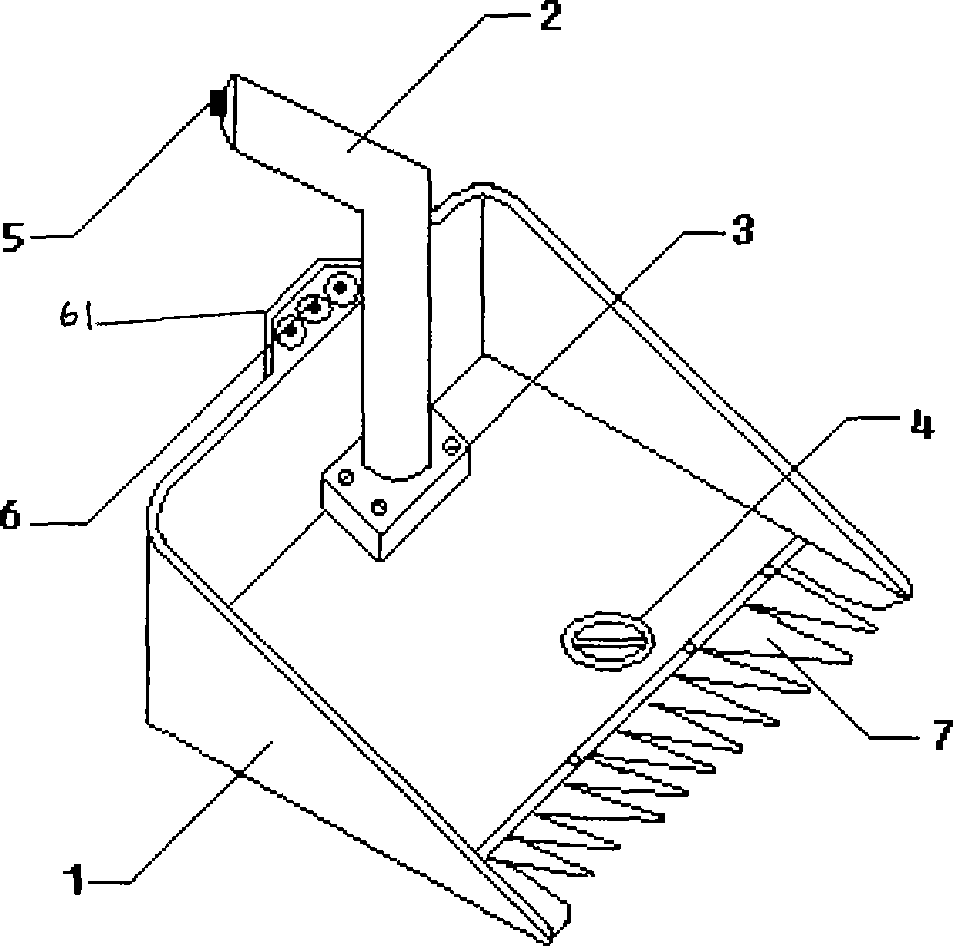

[0023] Such as figure 1 , figure 2 , image 3 As shown; the tea collection bucket 1 of the present invention can be made of metal or plastic, and a handle 2 for the operator to hold is also set on the tea collection bucket 1. Screw 71 is connected and fixed with a fixed blade 7 that one end is comb-toothed, and its knife tooth is outward, as figure 2 As shown; a comb-shaped oscillating blade 8 at one end is placed below the fixed blade 7, and its teeth are outward; the two blades overlap, and a movable screw 4 connects the fixed blade 7 and the oscillating blade 8 together , the swinging blade 8 just takes this movable screw 4 as the rotating shaft to slide back and forth driven by the eccentric mechanism, and a support 3 for installing a DC micromotor 10 is arranged on the rear end of the tea bucket 1, and the DC microm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com