Heat radiation structure of LED lamp backlight device

A technology for LED lamps and backlight devices, which is applied to cooling/heating devices of lighting devices, lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problem of no LED lamp backlight devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

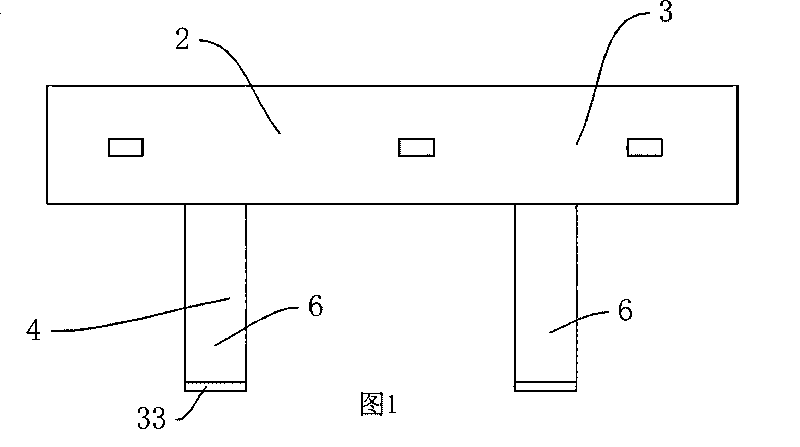

[0026] see Figure 1-3 As shown, the LED light backlight device includes a light bar 1, three LED lights 3 are arranged on the left end surface 2 of the light bar 1, and two connecting parts 4 protruding from the lower side of the light bar are arranged on the lower side of the light bar 1, and are connected to the light bar. The heat conduction layer 5 on the right end surface of the bar and the right end surface of the connecting part, and the positive and negative pins 6 are respectively arranged on the positive and negative pins 6 on the left end surfaces of the two connecting parts 4 . The material of the heat conduction layer is red copper. The silicone grease 33 at the lower end of the connection part 4 connects the positive and negative pins 6 with the heat conduction layer 5 . The heat on the positive and negative pins 6 mainly transfers heat to the heat conduction layer through the silicon grease and the light strip body in the form of heat conduction.

Embodiment 2

[0028] see Figure 1-3 , 7, 8, the led light backlight device includes a light bar 1, a backlight board 30 and a printed circuit board 10 electrically connected to the led light (not shown in the figure). Three LED lamps 3 are arranged on the left end surface 2 of the light bar 1, and two connection parts 4 protruding from the lower side of the light bar are arranged on the lower side of the light bar 1, and are connected to the right end surface of the light bar and the heat conduction layer on the right end surface of the connection part 5. The positive and negative pins 6 are respectively arranged on the left end surfaces of the two connecting parts 4 .

[0029] The light bar is connected to the side 31 of the backlight board. A heat dissipation layer 32 for dissipating heat from the backlight is provided on the upper and lower end surfaces of the backlight close to the light bar.

[0030] The printed circuit board 10 includes a base material 11 , a copper clad layer 12 o...

Embodiment 3

[0037] see Figure 4-6 As shown, the LED light backlight device includes a light bar 1, three LED lights 3 are arranged on the left end surface 2 of the light bar 1, and the heat conduction component is a heat conduction layer 5 connected to the right end surface, the upper side and the lower side of the light bar. The material of the heat conducting layer is copper. Positive and negative pins 6 are drawn out from the lower side. There is silicone grease 33 between the positive and negative pins 6 and the heat conduction layer. The heat on the positive and negative pins 6 mainly transfers heat to the heat conduction layer through the silicon grease and the light strip body in the form of heat conduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com