Antistatic ceramic floor and preparing method thereof

An anti-static, ceramic technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of inability to meet high-performance anti-static and long life, the anti-static performance is not stable enough, and cannot be applied in a large range, and achieves economical savings. The effect of production man-hours, simple construction, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

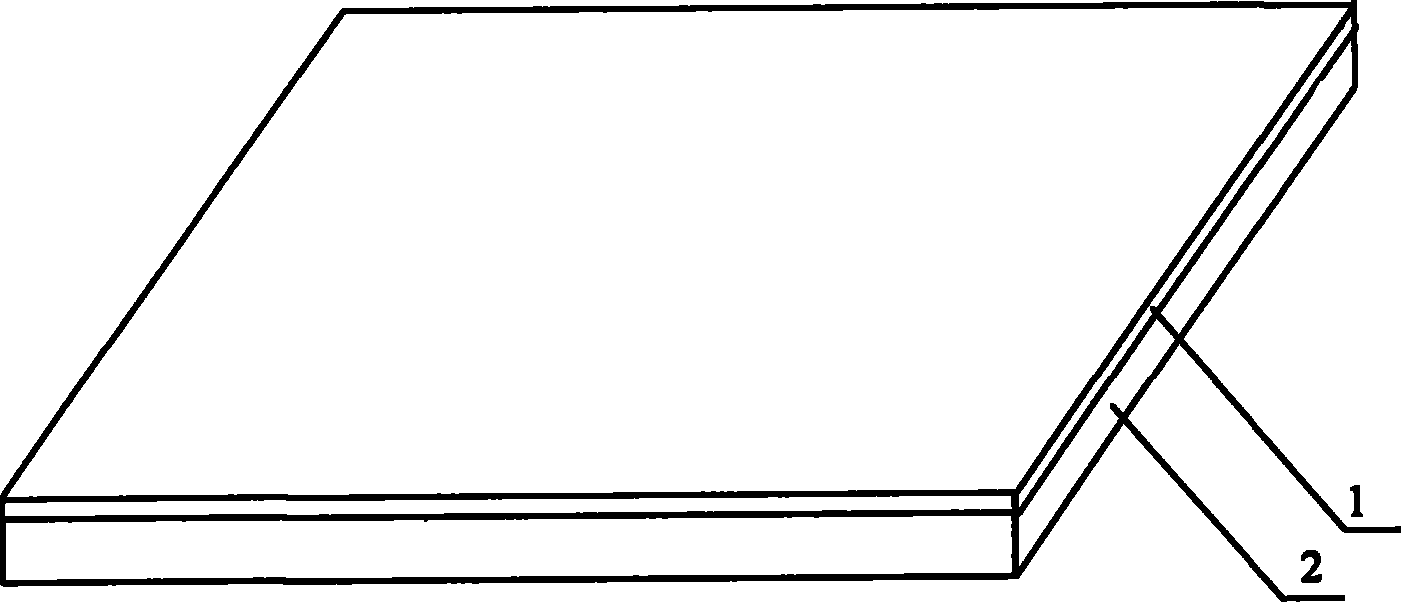

[0025] see figure 2 According to the existing process, the ceramic floor is first made through batching → ball milling → sieving → stale → spray drying → stale again → final molding and drying; at the same time, the glaze is made, and the conductive powder (Sn: 75%; Zn : 15%; Ti: 10%;), then add the conductive powder to the glaze according to the proportion of 30% of the total weight of the conductive powder, mix and stir evenly; after the ceramic floor molding process is completed, the glaze and the conductive powder The mixture is coated on the surface of the ceramic floor according to the preset printing scheme; fired, the firing temperature is controlled at 1180-1200°C for 50 minutes; the finished products are sorted to obtain qualified finished products.

Embodiment 2

[0027] The method is the same as in Example 1, the difference is that the components of the conductive powder are: Sn: 55%; Zn: 25%; Ti: 20%; the conductive powder accounts for 20% of the total weight and the conductive powder is added to the In the glaze, the firing temperature is controlled at 1180-1200°C for 40 minutes.

Embodiment 3

[0029] The method is the same as in Example 1, the difference is that the components of the conductive powder are: Sn: 55%; Zn: 20%; Ti: 25%; the conductive powder accounts for 25% of the total weight and the conductive powder is added to the In the glaze, the firing temperature is controlled at 1180-1200°C for 40 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com