Large-tonnage vertical shock insulation damping device

A technology of vertical shock isolation and shock absorbing devices, applied in protection devices, shockproof, infrastructure engineering, etc., can solve the problems that cannot be applied to high temperature environments, lack of vertical bearing capacity, and easy aging of rubber bearings, etc., to achieve Long service life, good recovery characteristics, simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

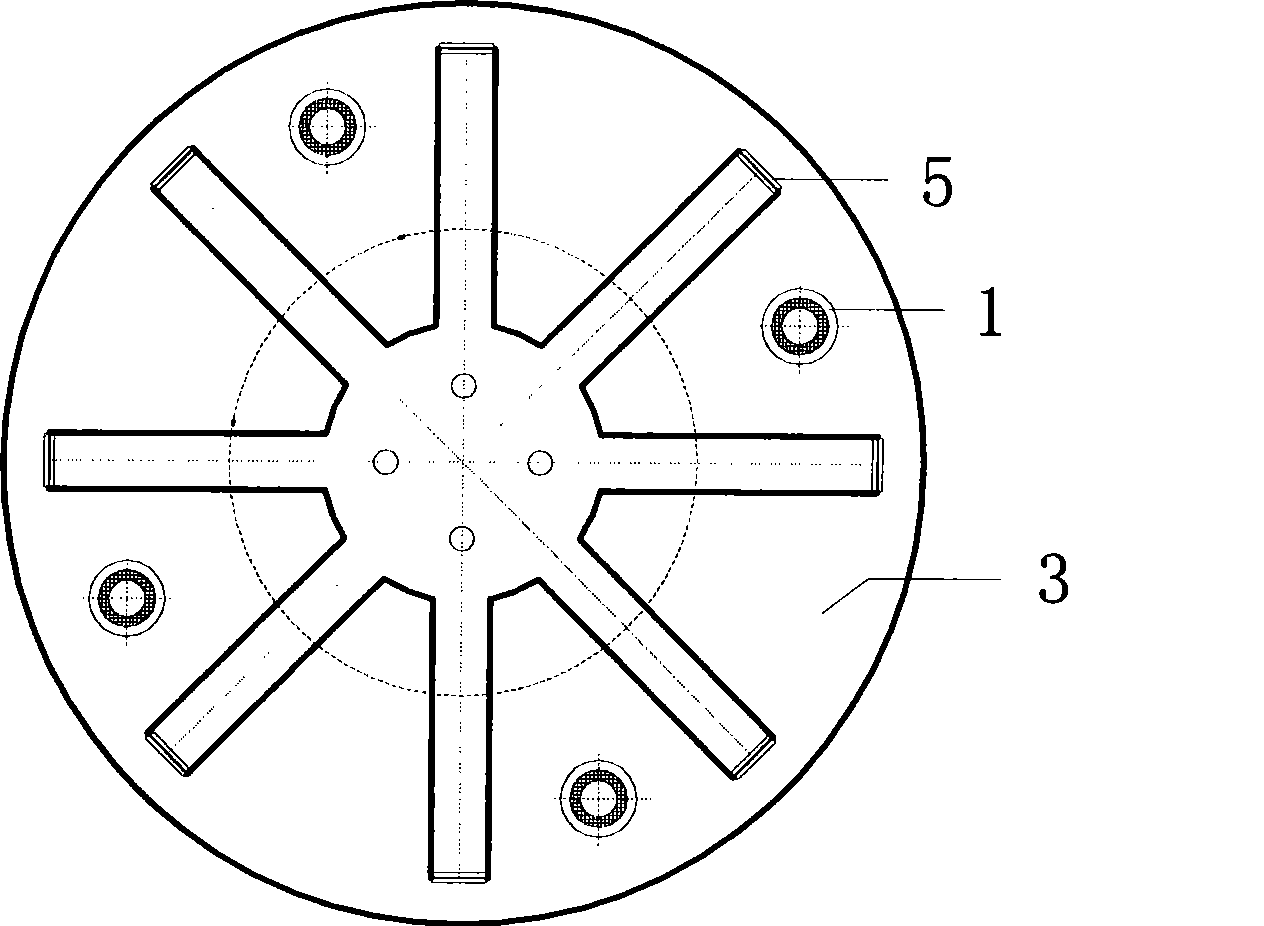

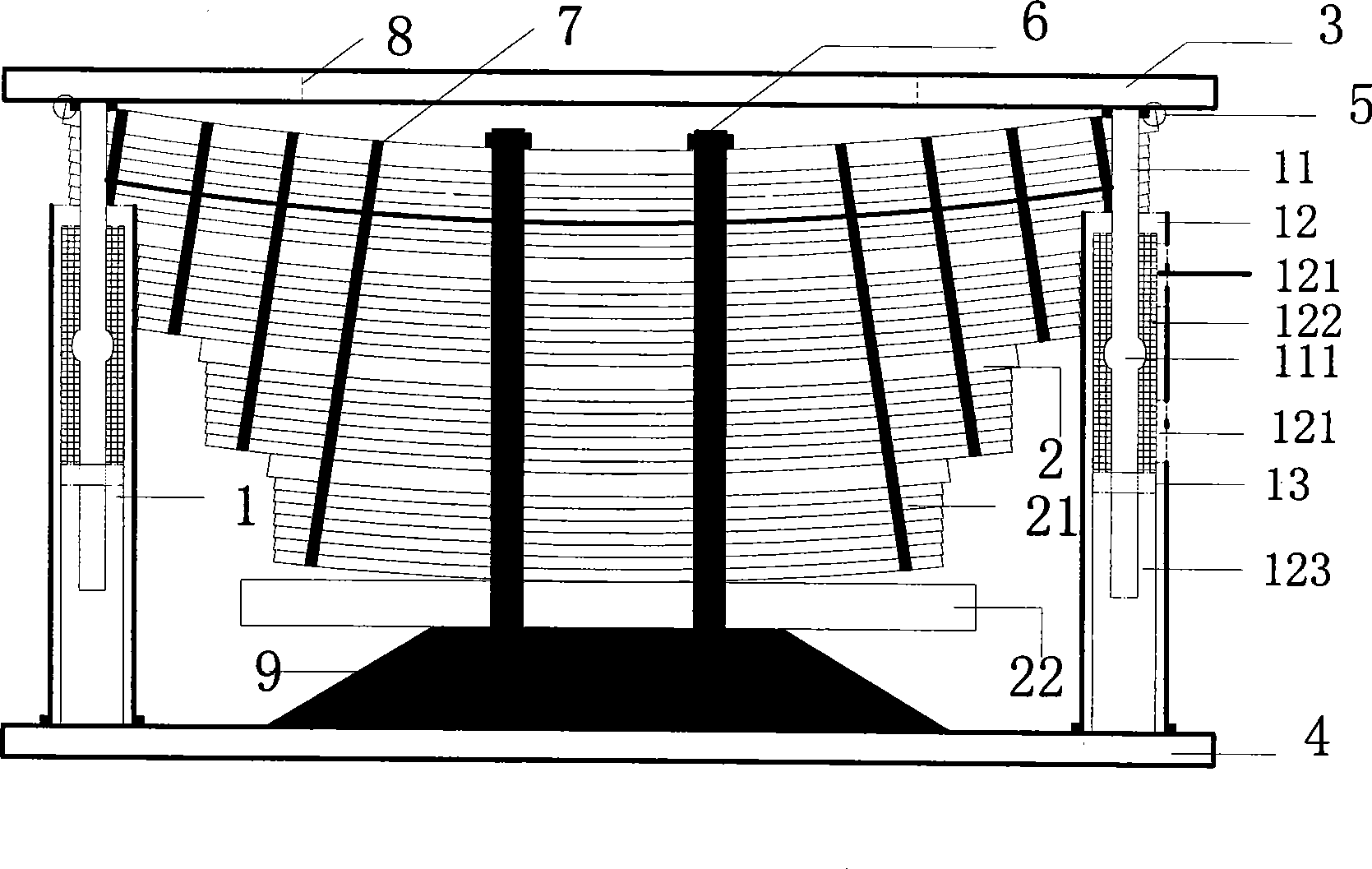

[0017] The large-tonnage vertical shock absorber of the present invention is composed of a lead squeeze damper 1 (also a viscoelastic damper, a viscous fluid damper or a metal damper) and a special leaf spring 2. In the overall structure, there is a leaf spring 2 in the middle, and a plurality of lead extrusion dampers 1 are symmetrically arranged around it. The upper part of each damper 1 is connected with the upper steel plate 3, and the lower part of each damper 1 is connected with the lower steel plate 4, so that all the dampers 1 are connected as a whole; the upper part of the middle leaf spring 2 and the upper steel plate 3 pass through the ball 5 Connected, the lower part is connected with the steel block 9 by bolts 6, and the steel block 9 and the lower steel plate 4 are integrally cast together. The lead extrusion damper 1 is composed of an outer steel cylinder 12 and a steel rod 11 located inside it, and the end steel plate 13 is located in the outer steel cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com