Trolley type rapier tape guide rail of rapier loom

A rapier loom, roller type technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of difficult to guarantee the size of guide rail grooves, difficult to install anti-friction materials, not suitable for mass production, etc., to ensure accurate performance, overcome positioning and wear problems, and ensure efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

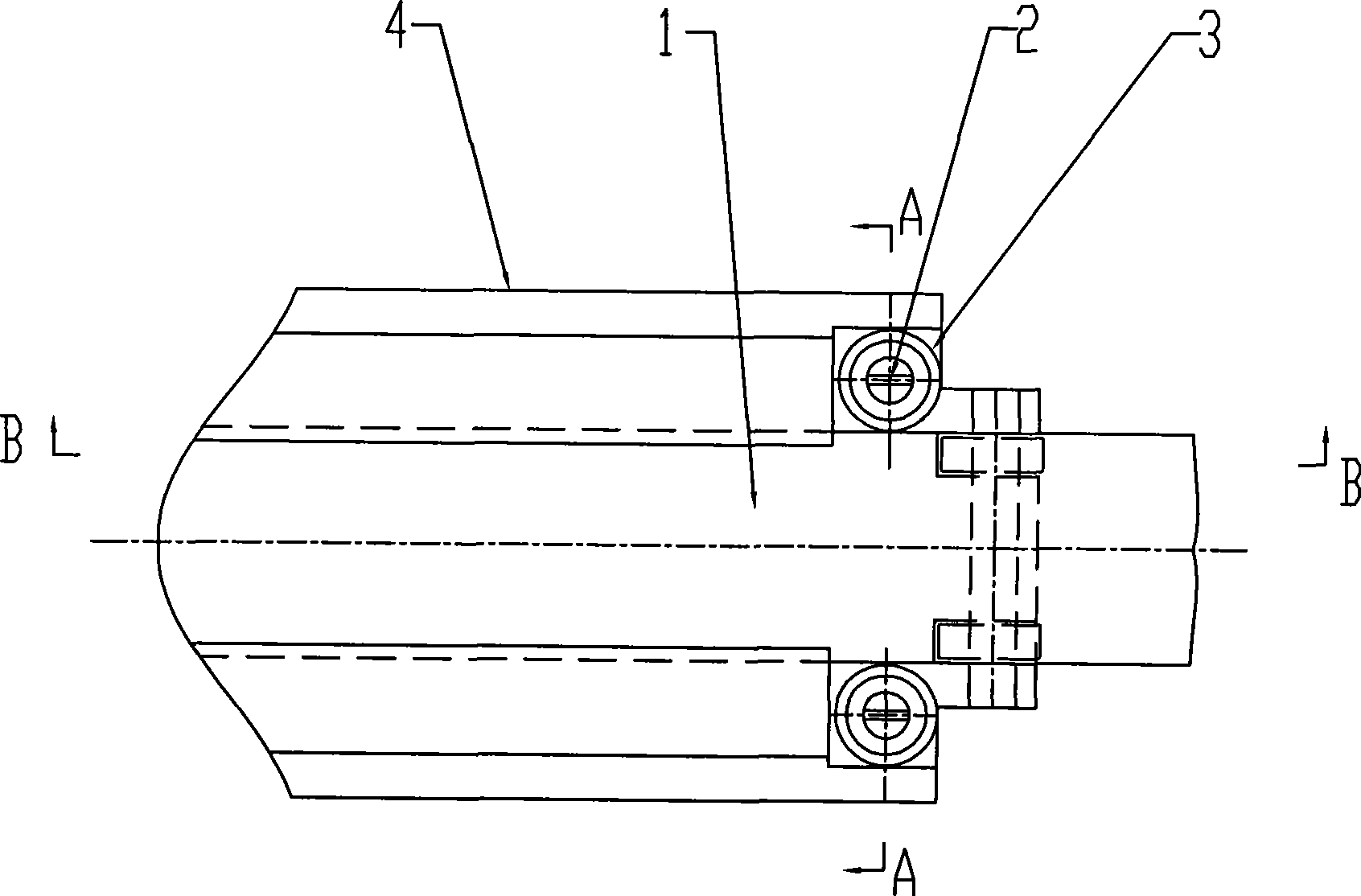

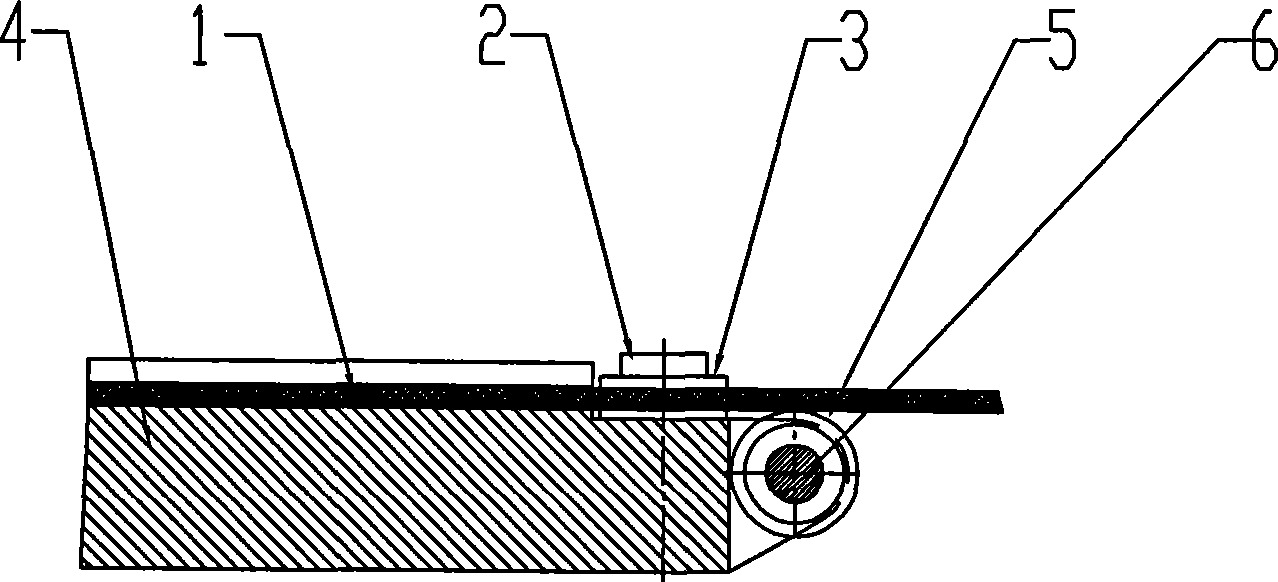

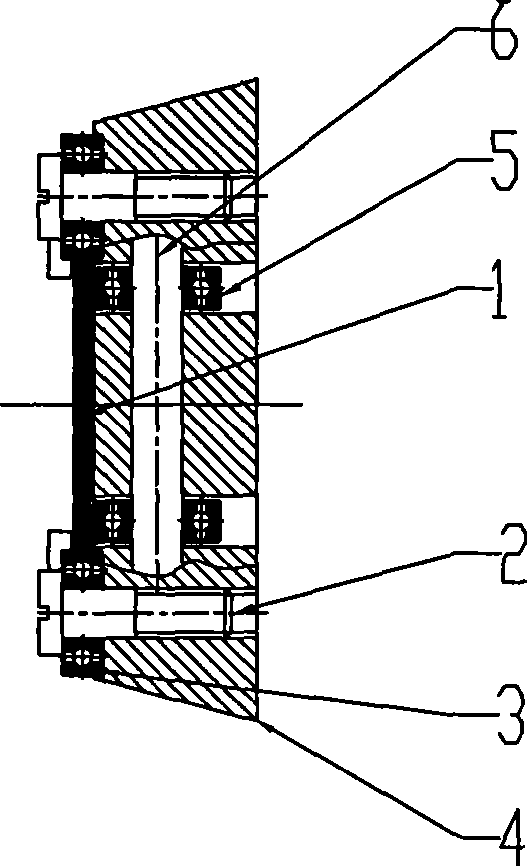

[0017] Rapier loom roller type rapier belt guide rail, including rapier belt 1, pin 2, lateral guide roller 3, rapier belt guide rail 4, lower support roller 5, pin shaft 6, lateral guide roller 3 is set on the rapier belt through pin 2 On the left and right sides of the guide rail 4, the lower support roller 5 is arranged on the lower part of the sword belt guide rail 4 through the pin shaft 6, the sword belt 1 is arranged on the sword belt guide rail 4 and the lower support roller 5, and the sword belt 1 is arranged on the side of the lateral guide roller 3. Inside, the sword belt 1 is slidingly connected with the sword belt guide rail 4, the lower support roller 5, and the lateral guide roller 3. When the sword belt 1 reciprocates at high speed along the sword belt guide rail 4, the sword belt contacts with the lateral guide roller 3 and the lower support roller 5 installed on the sword belt guide rail, so as to ensure the accurate positioning of the sword belt and reduce fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com