Soft polyurethane low-resilience foam and preparation thereof

一种低回弹、泡沫的技术,应用在芳族异氰酸酯基聚氨酯低回弹泡沫及其制备领域,能够解决胺封端聚环氧丙烷昂贵、难以获得软质聚氨酯低回弹泡沫、仅有限供应等问题,达到大配方组分范围的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

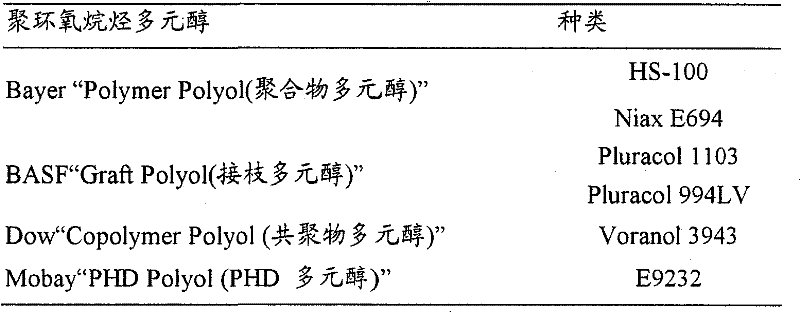

Method used

Image

Examples

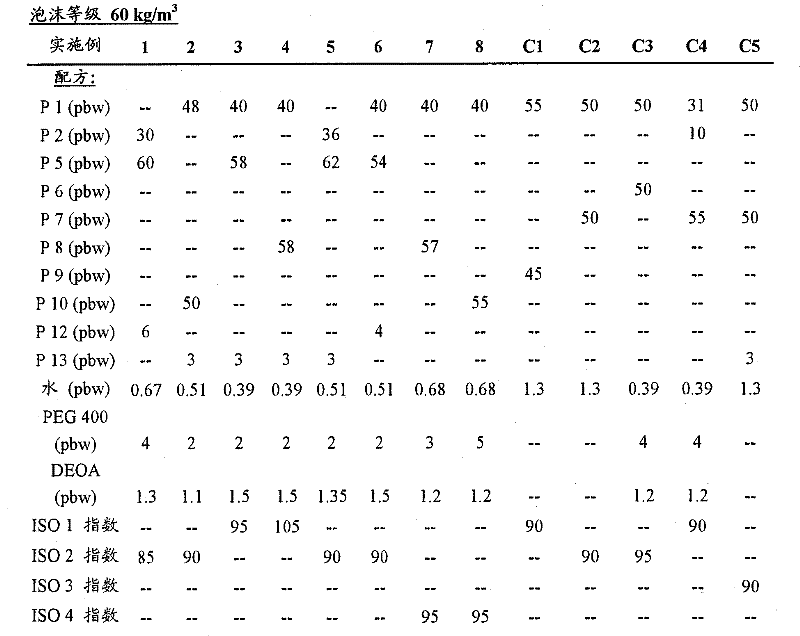

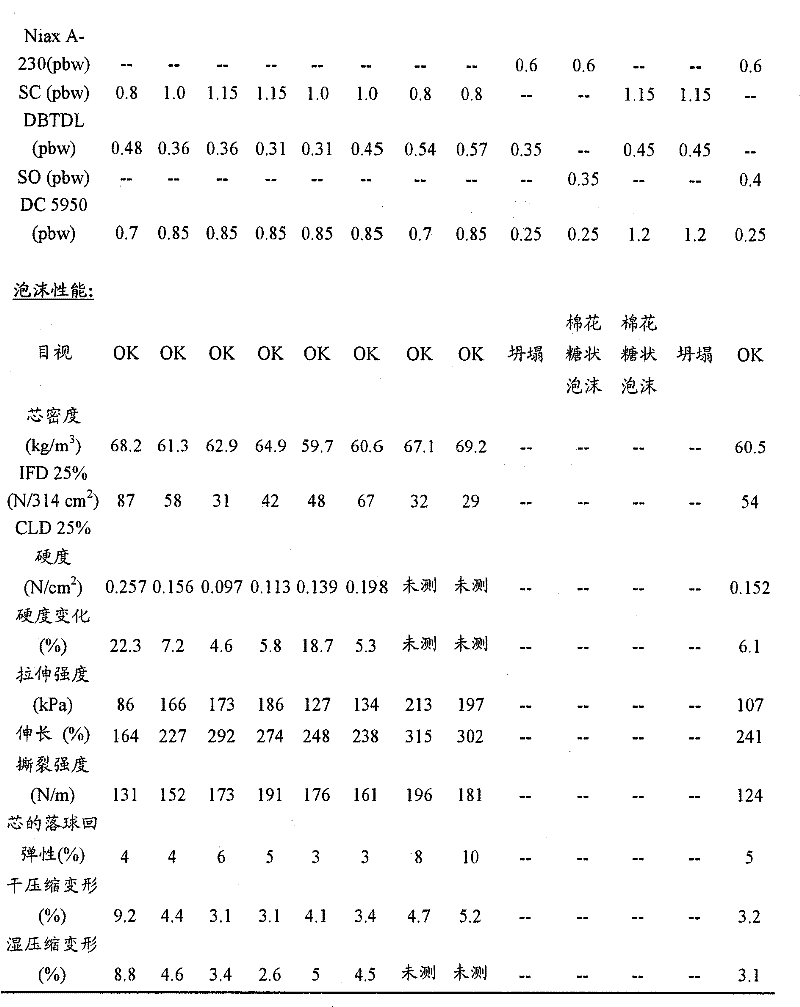

Embodiment 1-8 and comparative Embodiment C1-C5

[0149] The flexible polyurethane low-resilience foams of Examples 1-8 and Comparative Examples C1-C5 were prepared by mixing the components shown in Table 2. Condition all selected ingredients in a temperature-controlled room at 23±1°C for at least 24 hours before foaming. The ingredients, except the organotin compound and isocyanate, were premixed together in a 1.5 liter stainless steel beaker for 40 seconds using a Cowles type mixer set at a rotation speed of 1,500 rpm prior to adding the organotin compound. After premixing, the organotin compound (if used) was then added to the cup and mixed for an additional 20 seconds with the rotation speed set at 1,500 rpm. The selected isocyanate compound was then added to the resulting mixture and mixed with the resulting composition at 3,000 rpm for 5 seconds. The mixture was then poured into a 45 cm (L) x 45 cm (W) x 45 cm (H) paper-lined wooden box with the top open and foamed. After the foam reached its final height, it was allo...

Embodiment 9-16

[0156] Examples 9-16 were prepared using the same procedure used in the preparation of Examples 1-8, except that the selected polyols P3 and P4 were first melted in an oven at a temperature of 60±1°C. When the polyol was completely melted, the polyol was then moved to a conditioning room at 28±1°C for 6 hours before further foaming. All other selected ingredients were conditioned for at least 24 hours in a separate chamber controlled at 23±1°C for at least 24 hours prior to foaming.

[0157] The selected polyol P3 or P4 was first mixed to the other polyols using a Cowles type high shear mixer at 3,000 rpm for 60 seconds. The flexible polyurethane low-resilience foams of Examples 9-16 were prepared by mixing the components shown in Table 3. The ingredients, except the organotin compound and isocyanate, were premixed together in a 1.5 liter stainless steel cup for 40 seconds using a Cowles type mixer set at a rotation speed of 2,000 rpm prior to adding the organotin compound. ...

Embodiment 13

[0163] In Example 13, a closed-cell foam was obtained, and when the internal temperature began to drop, the foam began to shrink. The foam is broken by passing it twice through a pair of electric stainless steel roller breakers to prevent further shrinkage. The crushed foam was conditioned for at least 72 hours in a temperature controlled room at 23 ± 1 °C prior to further physical property testing. The physical properties described in Example 13 were determined using samples cut from crushed foam cores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com