Whole-feeding combine harvester equipped with lifting device

A combine harvester and full-feeding technology, which is applied to harvesters, loaders, cutters, etc., can solve the problem of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

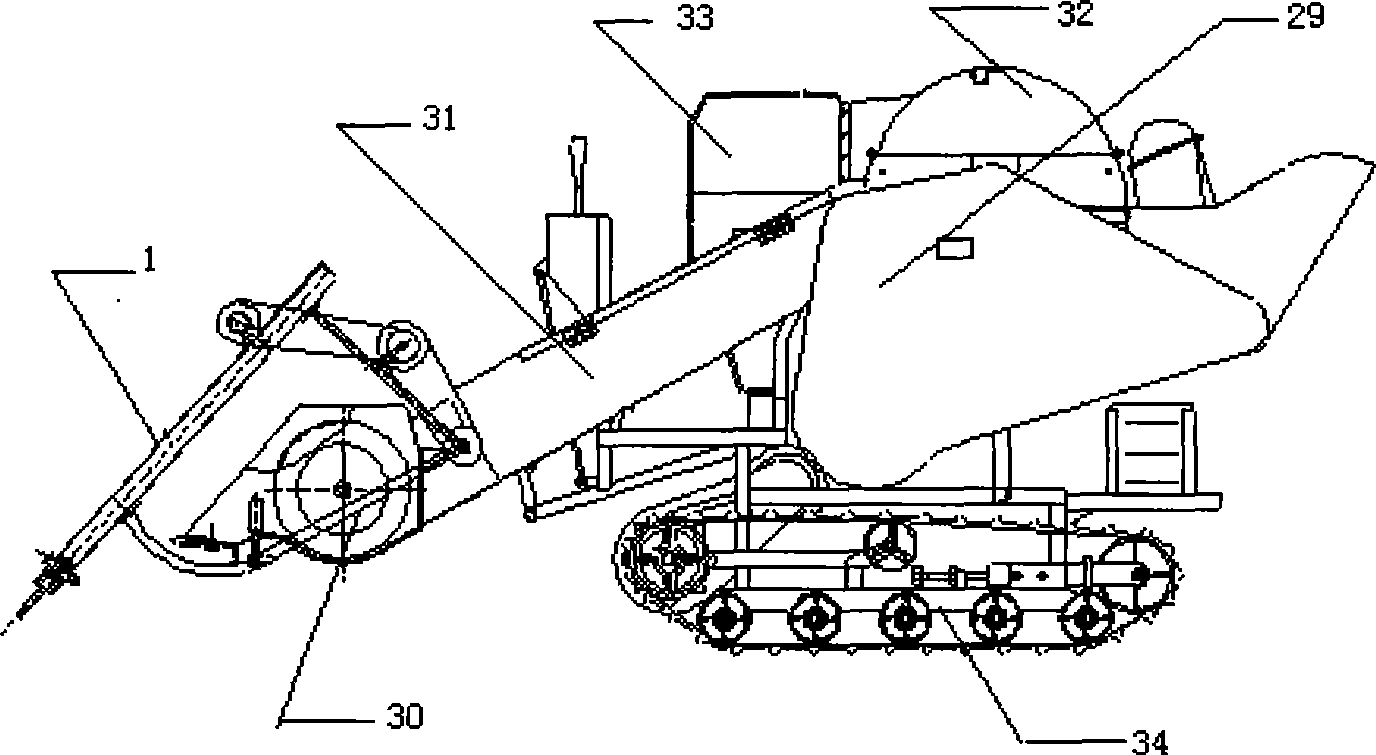

[0022] attached figure 1 The overall configuration of the embodiment of the present invention was explained.

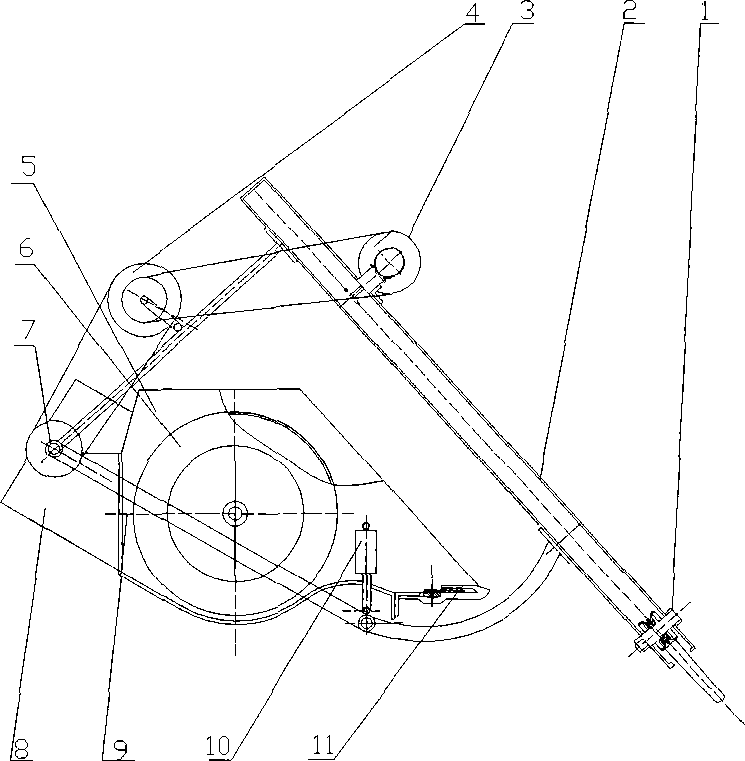

[0023] attached figure 2 One configuration of the header of the present invention is described.

[0024] Cutting platform 30 is made up of cutting bucket 5, horizontal auger 6, cutter 11, discharge port 8, transmission mechanism, and the front of cutting bucket 5 is equipped with tipping device 1.

[0025] The fall device 1 is made up of four side by side hold-up boxes, which are in a cuboid shape with open left and right sides, and a driven belt pulley 3 is provided on the hold-up box.

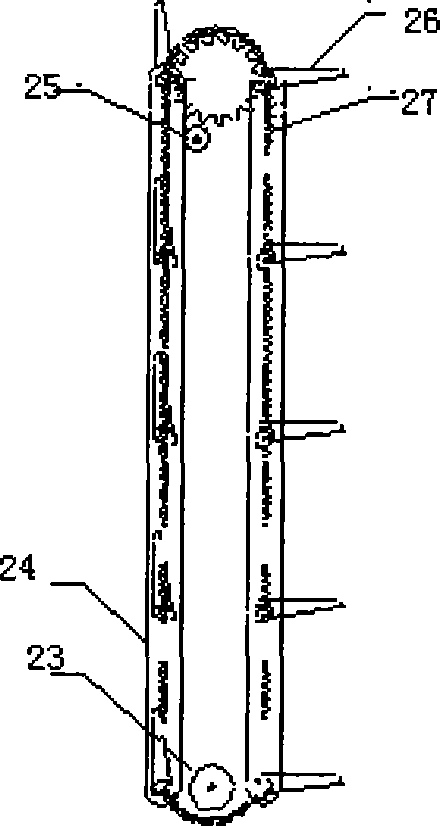

[0026] attached image 3 It illustrates the internal structure of a lifting box, which is equipped with a lifting guide rail 24, a free wheel 23, a tensioning wheel 25, an annular lifting chain 27, a lifting finger 26, and the lowest point of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com