Auxiliary correcting device of exposure image partial difference

A technology for correcting devices and deviations, which is applied in the field of photographic plate-making technology, can solve problems such as complex operations, and achieve the effect of ensuring image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

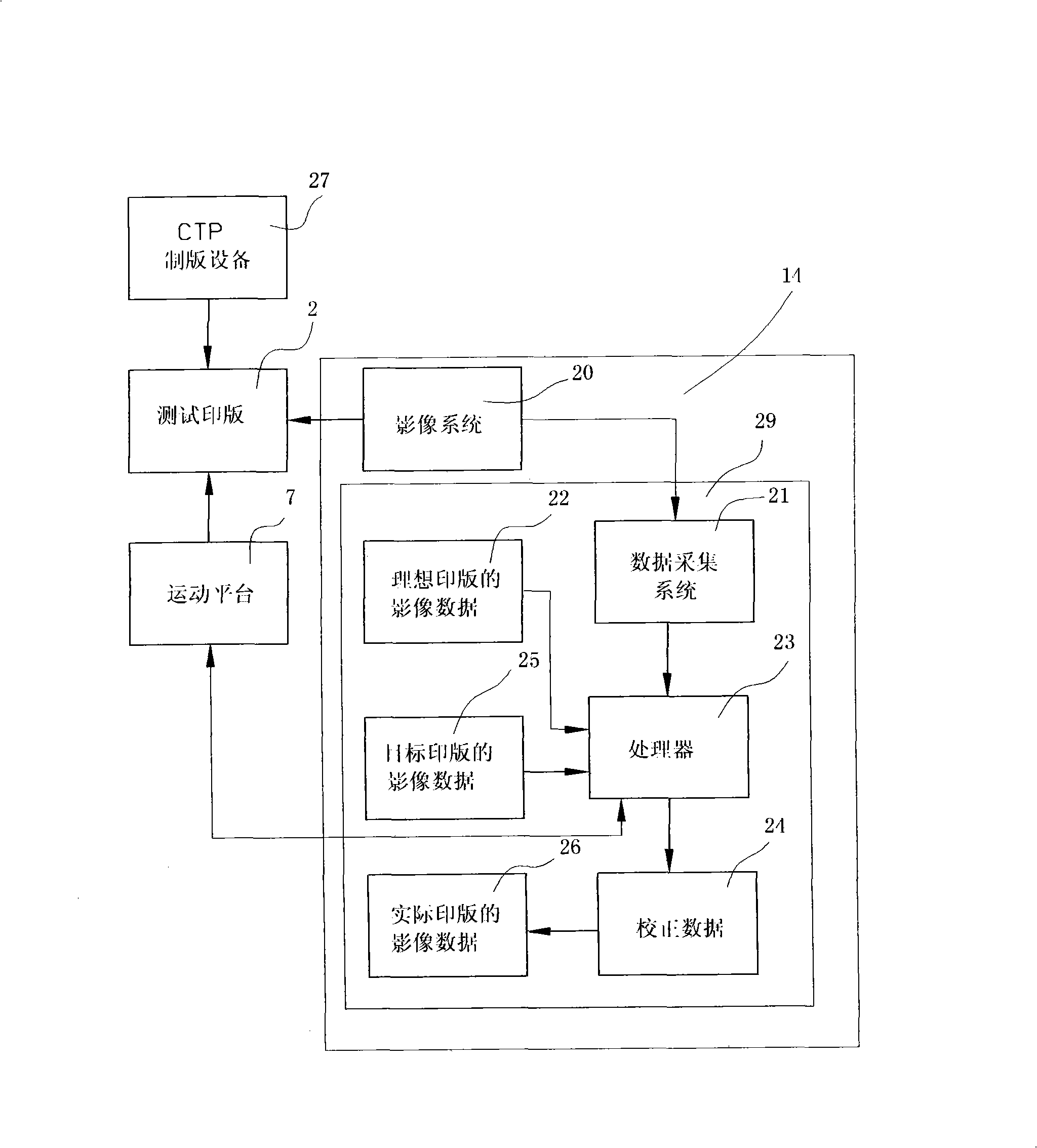

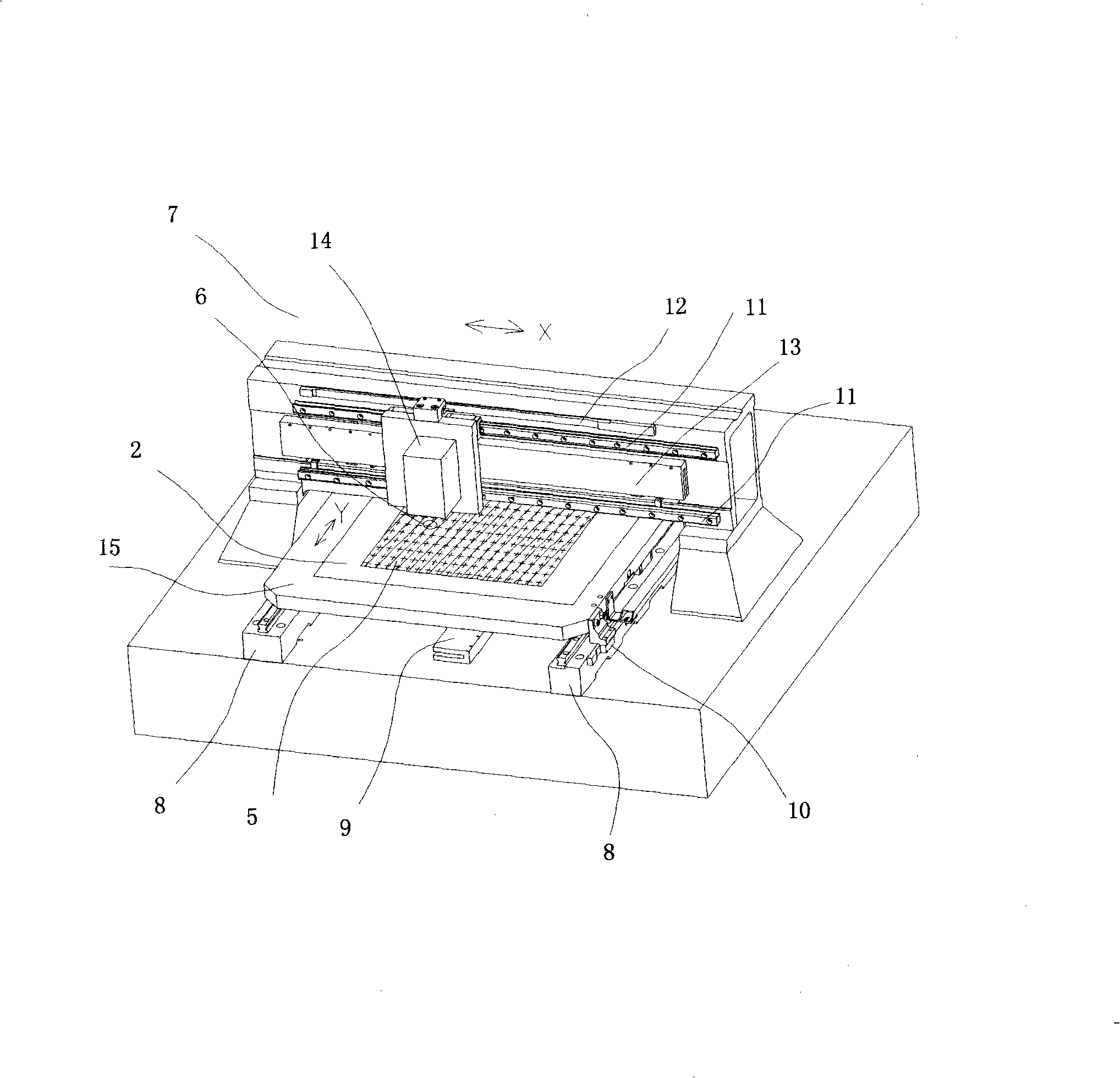

[0022] Further details will be given below in conjunction with the preferred embodiments shown in the accompanying drawings.

[0023] Such as figure 1 Shown is a three-dimensional structure diagram of a CTP plate-making equipment, and the auxiliary correction device of the present invention can correct the exposure deviation occurring in the plate-making equipment. Although in this embodiment, the CTP plate-making equipment is an external drum type, it may also be an internal drum type actually. The composition of the CTP plate making equipment includes:

[0024] A cylindrical imaging drum 1, a printing plate 2 covered with photosensitive material placed on the outer surface of the cylindrical imaging drum 1, an exposure device 3, and a linear motion mechanism 4 for carrying the exposure device 3 and moving along the X direction in the figure.

[0025] The imaging principle of this CTP plate-making equipment is: the image processing is to carry out image division processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com