Full hydraulic furnace pounding machine

A furnace pounding machine, full hydraulic technology, applied in the direction of furnaces, mechanical equipment, furnace components, etc., can solve problems such as easy-wearing rollers, deformation of rotating plates, etc., to achieve the effect of protection against deformation, stable performance, and full of creativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

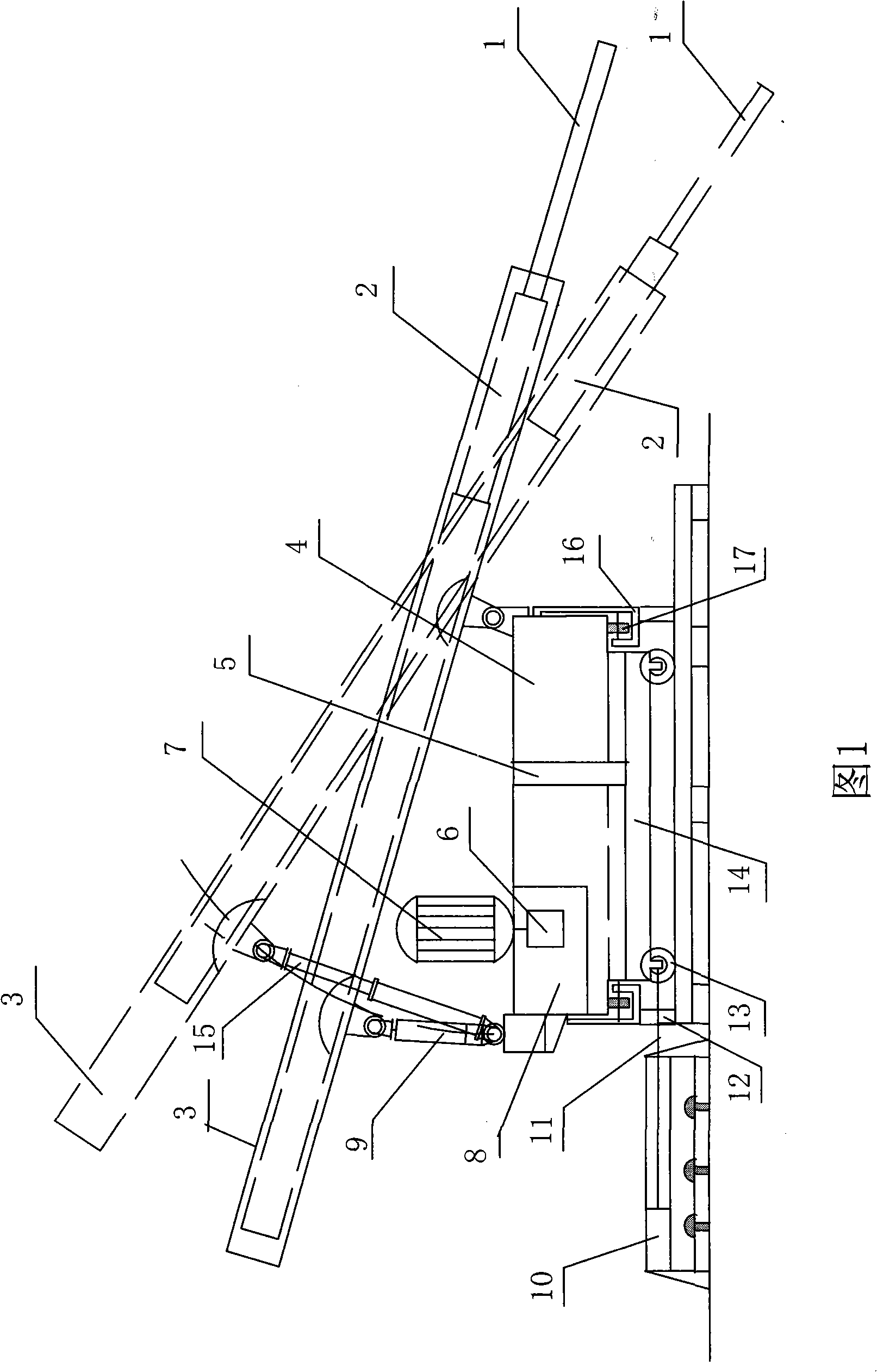

[0027] The full hydraulic furnace stamping machine includes a carrying mechanism, a furnace stamping mechanism, a power mechanism, and a slewing beam; the carrying mechanism includes a base 14 and a walking cylinder 10; wheels 13 are arranged under the base 14, and columns 12 are arranged under the four corners of the base 14. The wheel bracket at the rear end of the base 14 is tightly connected with the movable connecting rod 11 at the front part of the traveling oil cylinder 10, and the traveling oil cylinder 10 is fixed on the foundation.

[0028] The furnace pounding mechanism includes an outer arm 3, an inner arm 2, a pounding head 1, and a luffing oil cylinder 9; an inner arm 2 is arranged inside the outer arm 3, and the inner arm 2 and the outer arm 3 are dynamically matched and connected by hydraulic pressure. The front end of the arm 2 is provided with a tamping head 1, the tamping head 1 is fixedly connected with the inner arm 2, the rear part of the outer arm 3 is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com