Control method for getting wind process for kiln hood waste heat boiler in dry cement residual heat utilization and apparatus thereof

A dry-process cement and waste heat boiler technology, applied in cement production, clinker production, etc., can solve the problems of unutilized low-temperature waste heat, fluctuating exhaust gas temperature, and cooling effect of difficult cement clinker, etc. The effect of steam production, increasing inlet air temperature and steam production, and improving comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

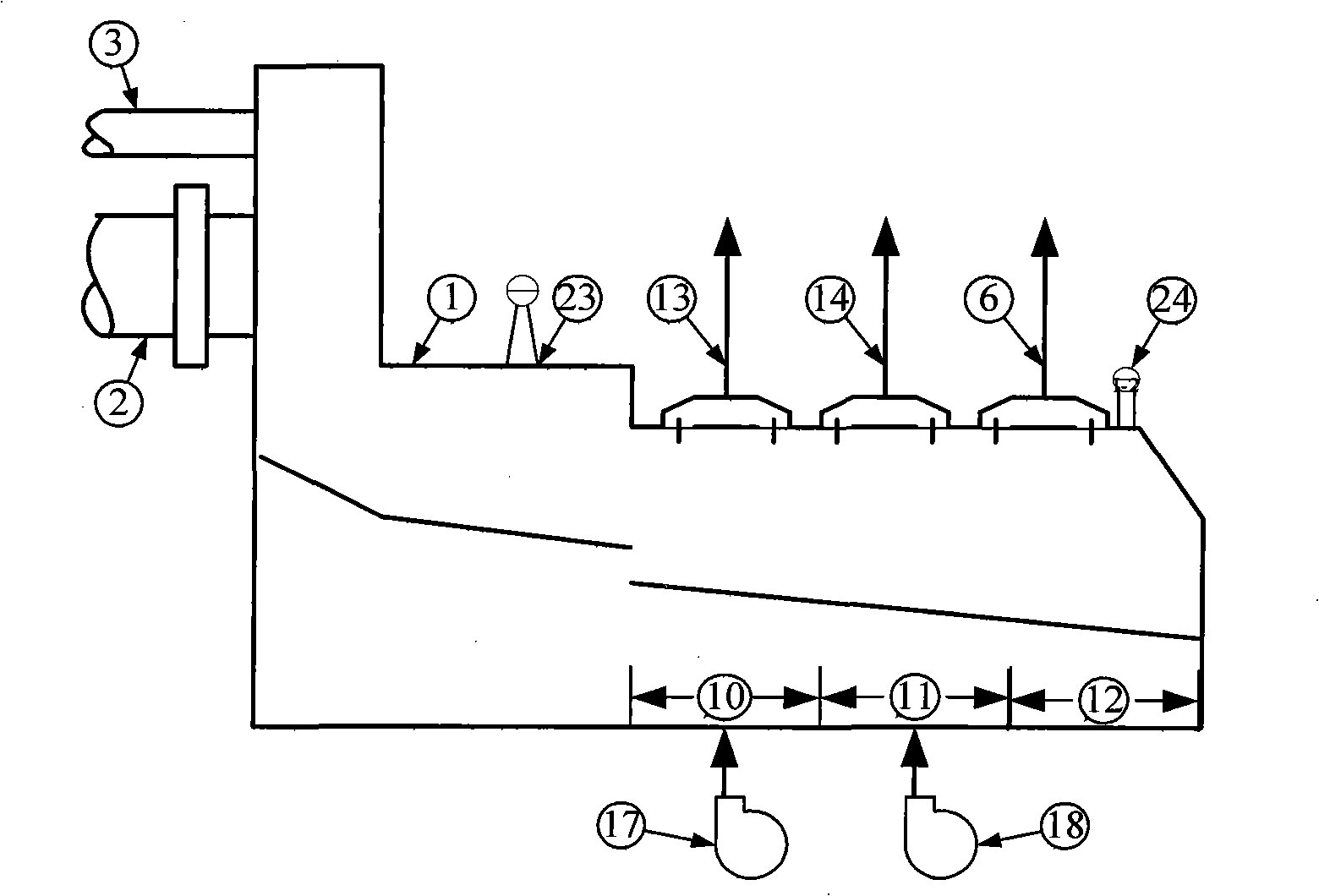

[0017] Take the specific practical application in the 4.5MW waste heat power generation project of the 2000t / d new dry process cement line as an example. The cement production line was put into operation in 2005, and the waste heat power generation was connected to the grid for power generation in May 2007. Due to frequent and large fluctuations in the process parameters of the cement production line, the waste heat power generation system is often seriously affected. The steam production of the waste heat boiler at the kiln head fluctuates greatly, and the waste heat power generation system does not operate normally. Therefore, the cement plant decided to increase the hot air circulation and control method of the cooler to stabilize and increase the steam output of the waste heat boiler furnace at the kiln head. In order not to affect the stable and safe operation of the relevant processes of the cement production line, in this application case, the hot air circulation and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com