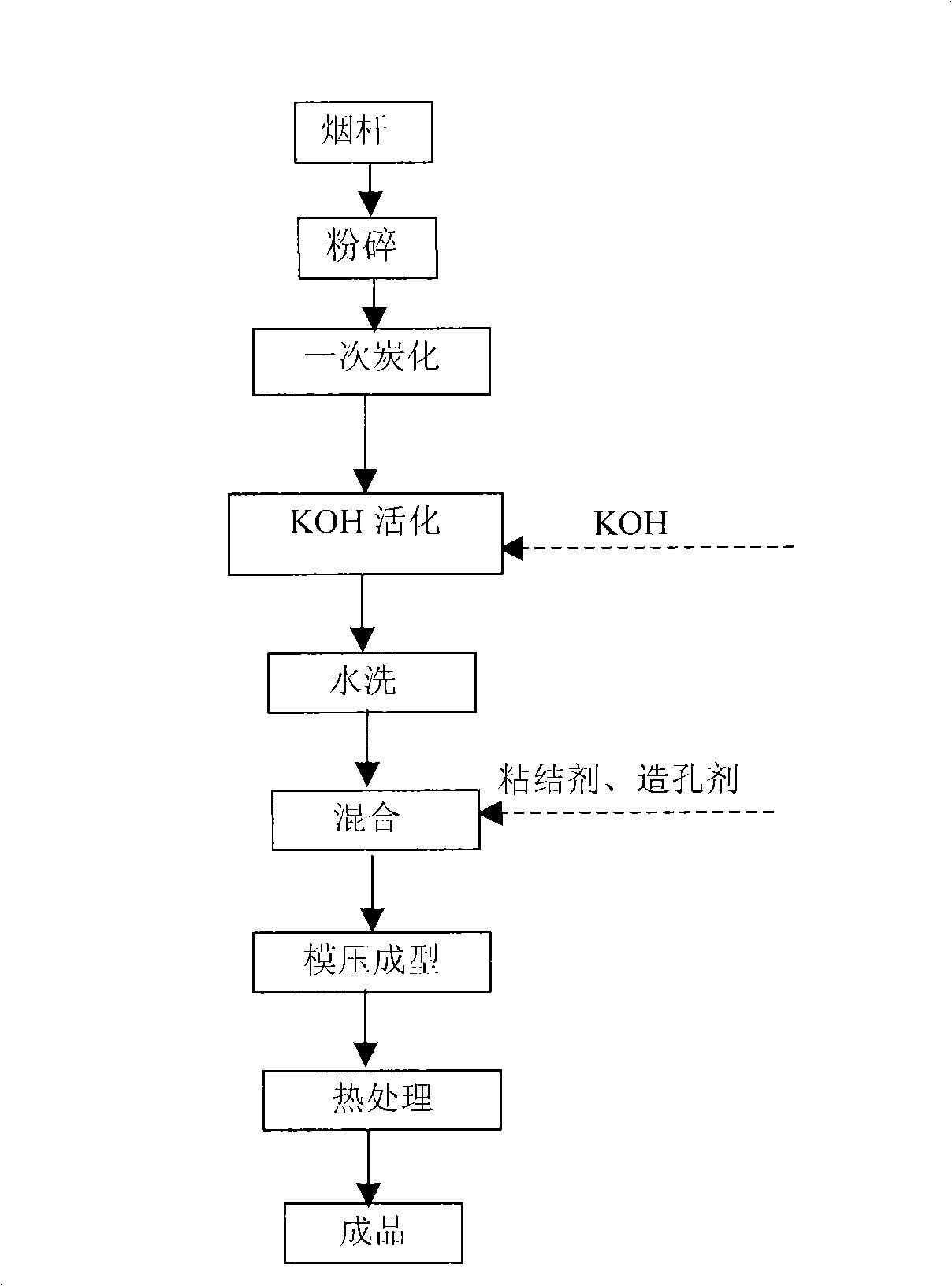

Method for preparing pressed active carbon from tobacco stalk

A technology for shaping activated carbon and tobacco stalks, which is applied in the field of preparing shaped activated carbon, which can solve the problems of affecting the adsorption effect, difficulty in scale-up, inconvenient use, etc., and achieve increased volume adsorption, good social and economic benefits, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Tobacco stems produced in Mengzi County, Yunnan Province are used as raw materials.

[0025] After crushing 100g of the above tobacco rod raw material to 0.5-0.8mm, put it into a tubular resistance furnace, under the protection of nitrogen, heat and carbonize at a heating rate of 10°C / min, raise it to 300-400°C, and keep it warm for 30-60min; Mix the carbonized tobacco rod with KOH evenly, KOH / C is 2-3.5, under the protection of nitrogen, heat and activate at a heating rate of 5°C / min, raise it to 400°C, keep it for 30min, and then heat it at a temperature of 10°C / min Raise the heating rate to 700-800°C and keep it warm for 30-90 minutes; wash the activated sample with water to obtain powdered activated carbon; then mix powdered activated carbon with 10-30% sodium carboxymethyl cellulose, and 5-15 % of calcium carbonate pore-forming agent, and under the pressure of 10-15Mpa, press it into a round cake-shaped carbon block with a diameter of 3-5cm and a thickness of 0.4-0...

Embodiment 2

[0027] Tobacco stems produced in Mile County, Yunnan Province are used as raw materials.

[0028] After crushing 100g of the above tobacco rod raw material to 0.5-0.8mm, put it into a tubular resistance furnace, under the protection of nitrogen, heat and carbonize at a heating rate of 10°C / min, raise it to 300-400°C, and keep it warm for 30-60min; Mix the carbonized tobacco rod with KOH evenly, KOH / C is 2-3.5, under the protection of nitrogen, heat and activate at a heating rate of 5°C / min, raise it to 400°C, keep it for 30min, and then heat it at a temperature of 10°C / min Raise the heating rate to 700-800°C and keep it warm for 30-90 minutes; wash the activated sample with water to obtain powdered activated carbon; then mix the powdered activated carbon with 10-30% polyvinyl alcohol and 5-15% carbonic acid Calcium pore-forming agent is mixed, and under the pressure of 10-15Mpa, it is pressed into a round cake-shaped carbon block with a diameter of 3-5cm and a thickness of 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com