Inkjet head device

An inkjet device and inkjet head technology, applied in printing devices, power transmission devices, printing and other directions, can solve problems such as poor coating state, film streaks, and waste of coating liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described by taking an inkjet coating device as an example.

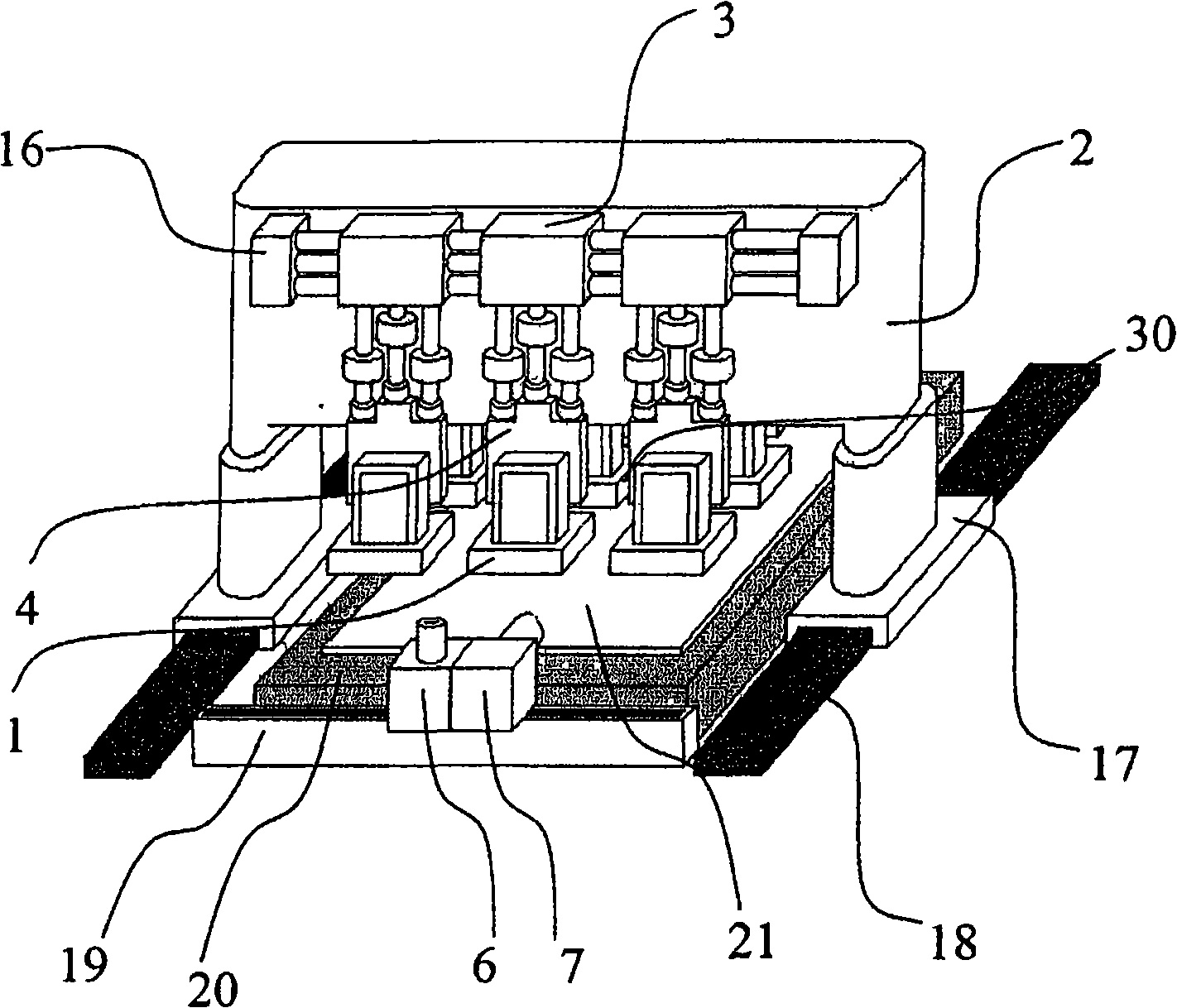

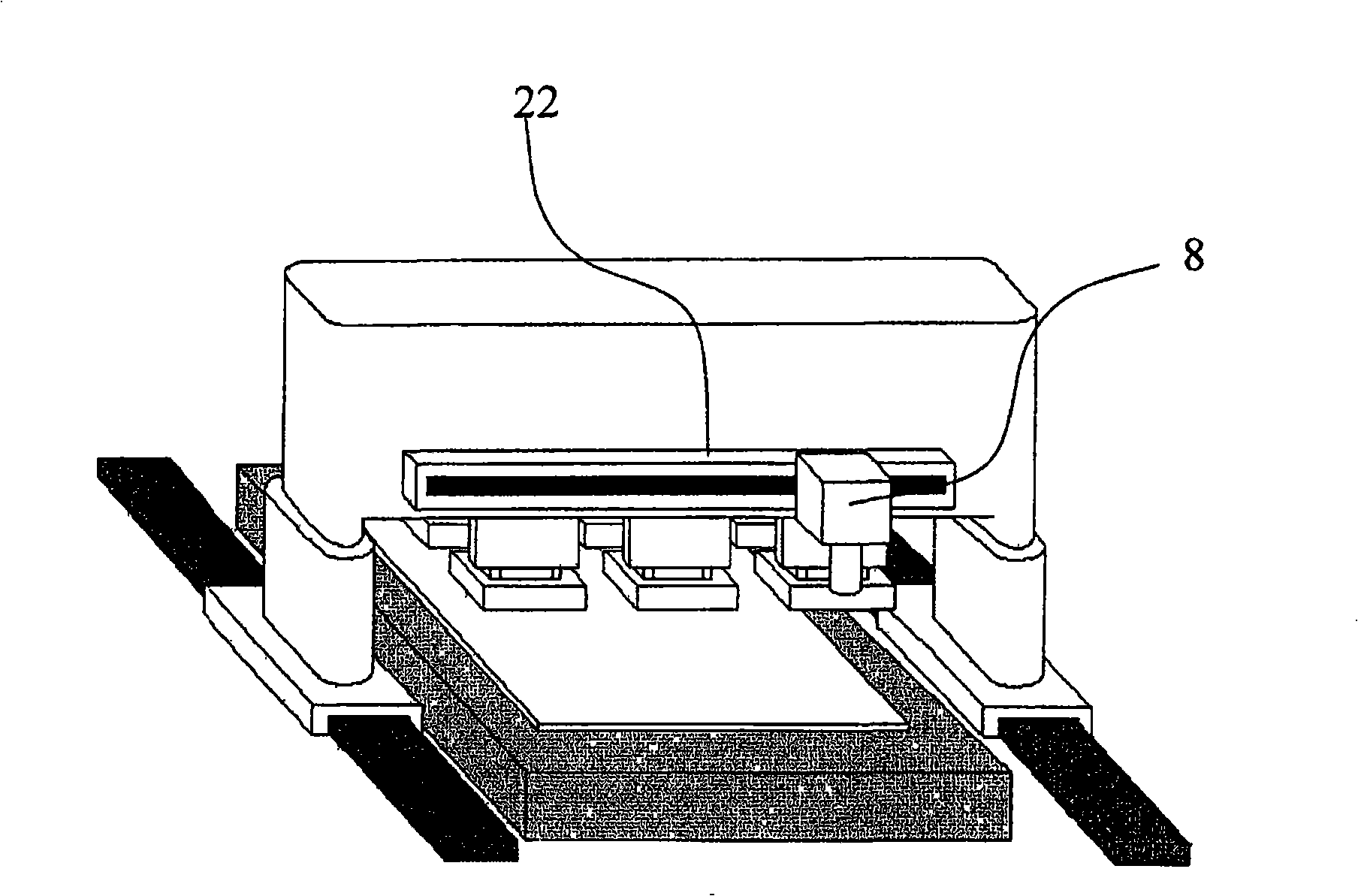

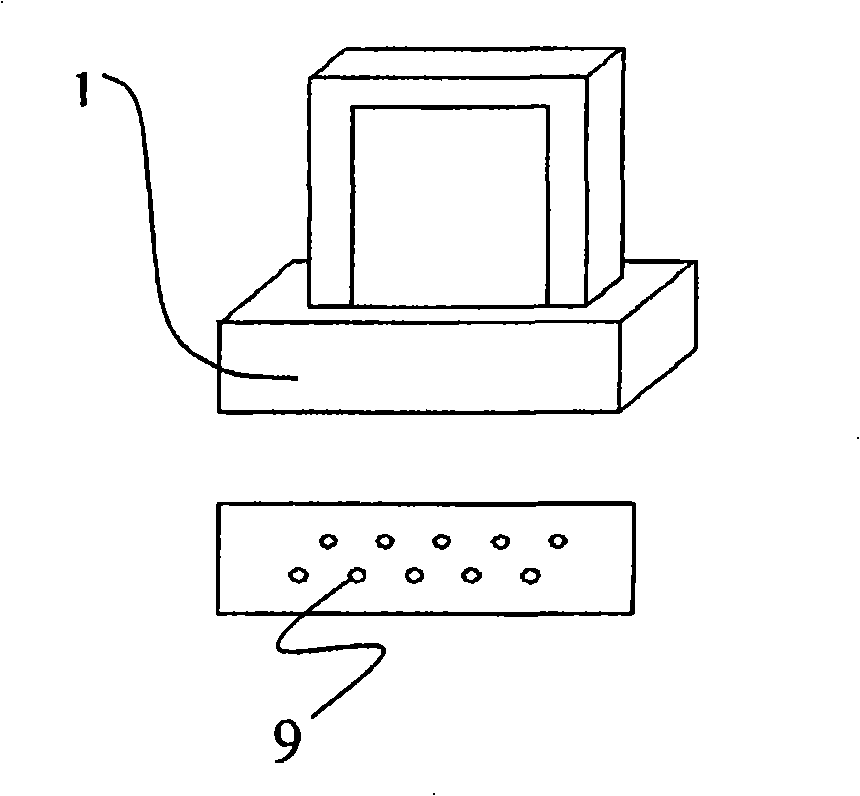

[0023] exist Figure 1~2 , is a schematic diagram showing six inkjet heads mounted as an inkjet coating device.

[0024] In this inkjet apparatus, there is provided a substrate stage 20 on which a substrate 21 as an object to be coated is placed and fixed on the stage by a suction suction mechanism not shown. A moving frame 2 configured to straddle the substrate stage 20 and move in the front-rear direction is provided. On the movable frame 2, three inkjet heads 1 (hereinafter simply referred to as heads) are provided so as to be movable in the longitudinal direction of the frame (left-right direction) on the front side, and three heads 1 are similarly provided on the rear side. Both legs of the moving frame 2 are provided with a moving table 17 provided with a linear motor, and by driving the linear motor, it can move in the front-rear direction on a linear rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com