A method and a device for transferring a tail

A narrow strip and conveying device technology, applied in papermaking, paper machine, wet end of paper machine, etc., can solve the problems of safety hazards, ineffective paper threading strips, etc., and achieve the effect of great chance of success

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

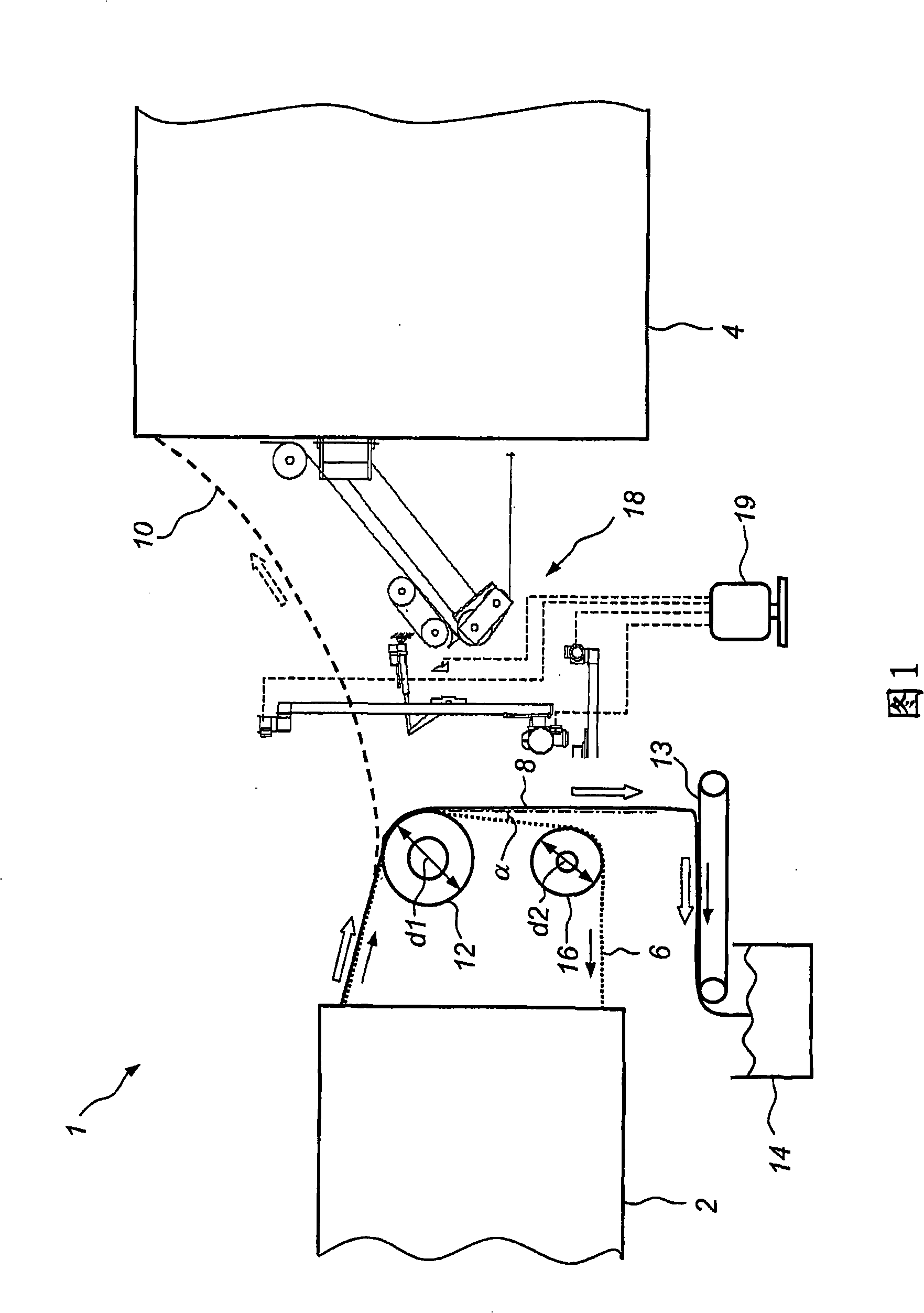

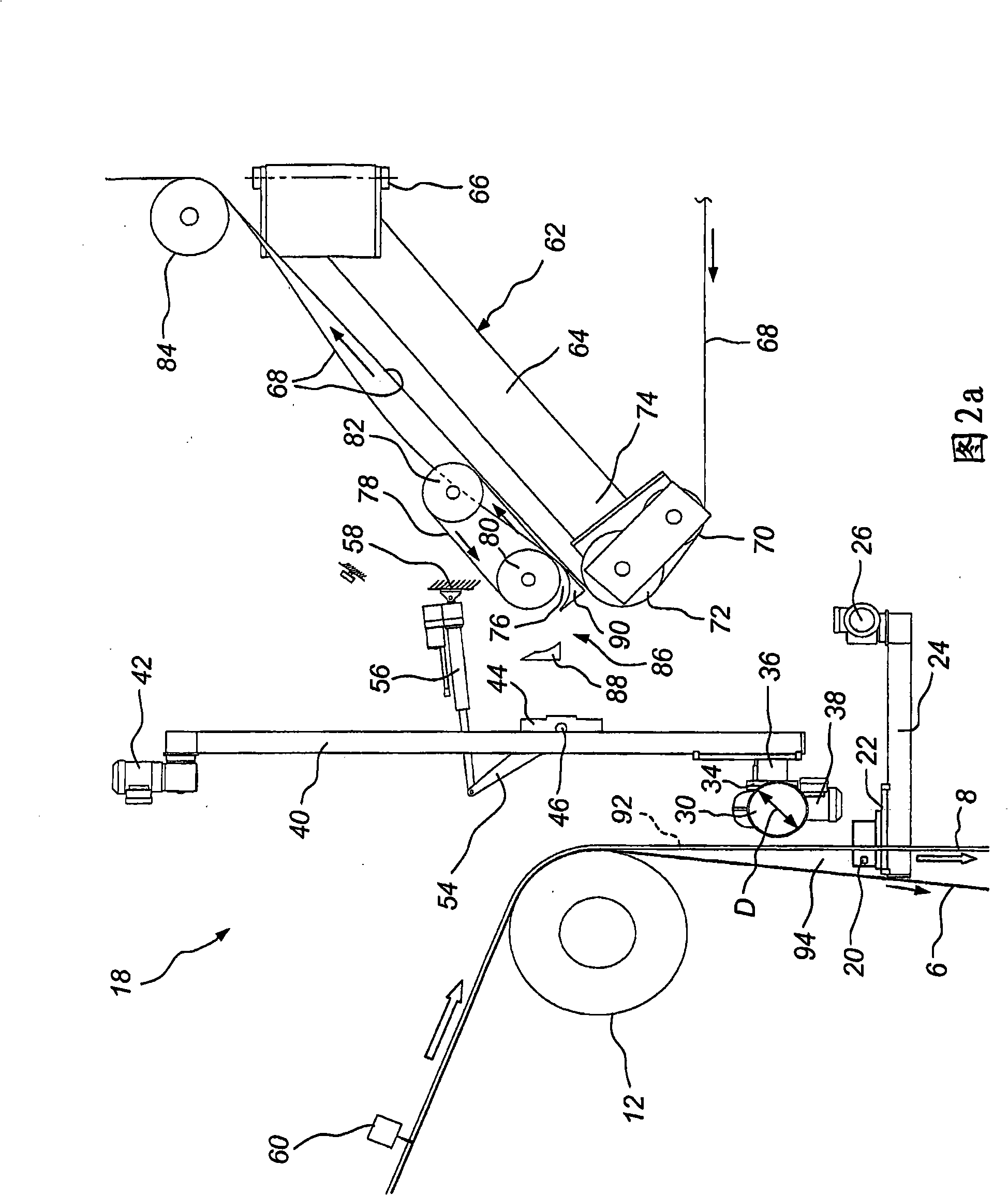

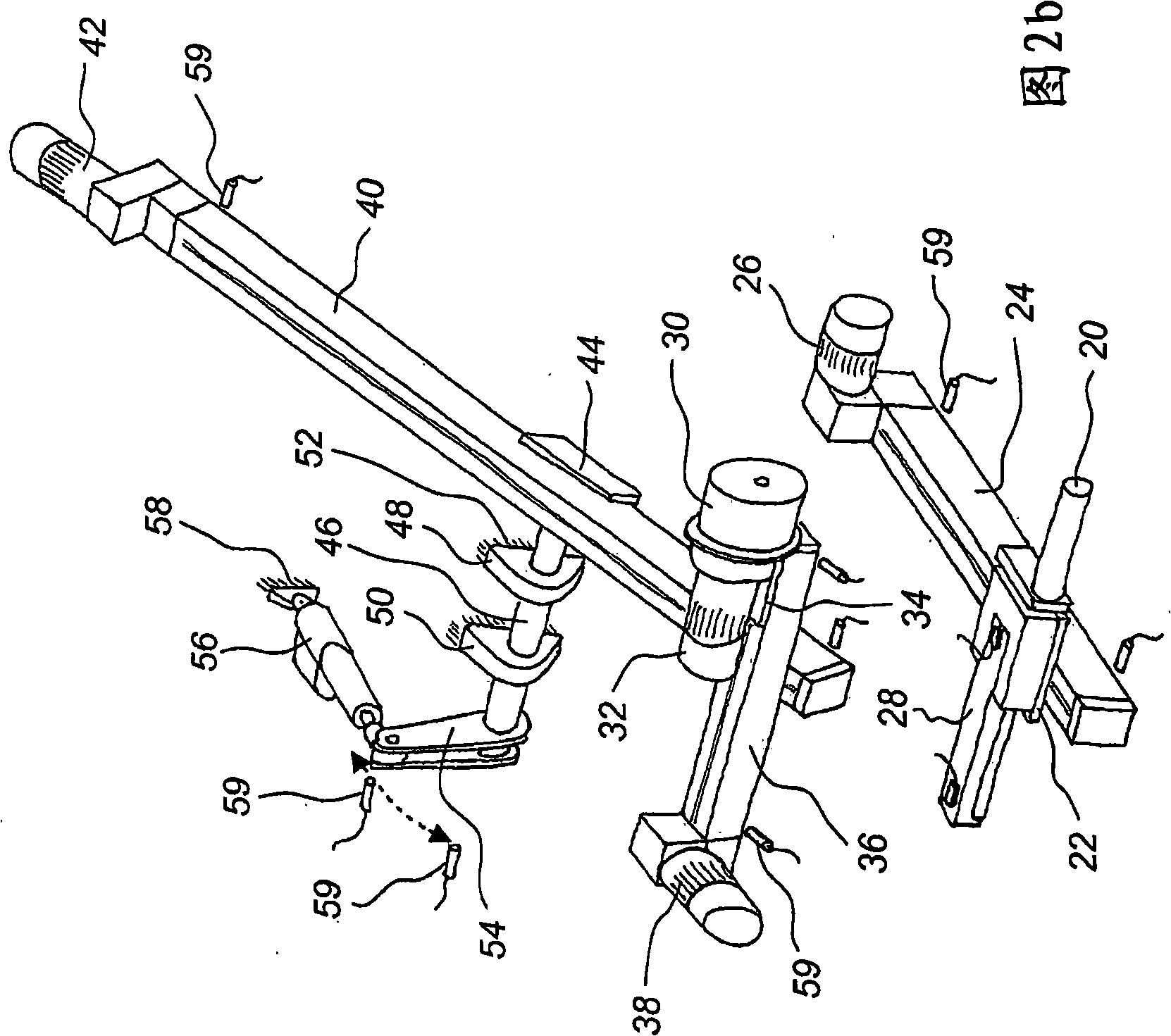

[0044] Figure 1 shows a pulp production equipment 1 suitable for the production of market pulp, that is, pulp based on cellulose fibers obtained by pulping or bleaching. The pulp production plant 1 includes a first treatment unit in the form of a wet forming table 2 and a second treatment unit in the form of a pulp dryer 4. The slurry of cellulose fibers is fed to the wet forming station 2 from an unshown slurry tank. In the wet forming station 2, the slurry is fed to an unshown forming wire according to a principle known per se, and then transferred to the press liner 6 and then squeezed between unshown press rolls to form a The cellulose-based fiber paper web 8 transferred by the liner 6 is pressed. After the wet forming station 2, the paper web 8 has a dry solid content of approximately 50%. The thickness of the paper web 8 is about 1.5-2.5 mm just after the wet forming station 2. The paper web 8 usually has a width of 3-10 meters. The paper web is then assumed to be transferre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com