Processing system for process object and thermal processing method for process object

A heat treatment method and the technology of the object to be processed are applied in thin material processing, transportation and packaging, semiconductor/solid-state device manufacturing, etc., which can solve the problems of production reduction and achieve the effect of preventing thermal damage and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, a preferred example of the processing system for an object to be processed and the method for heat treating an object to be processed according to the present invention will be described in detail with reference to the drawings.

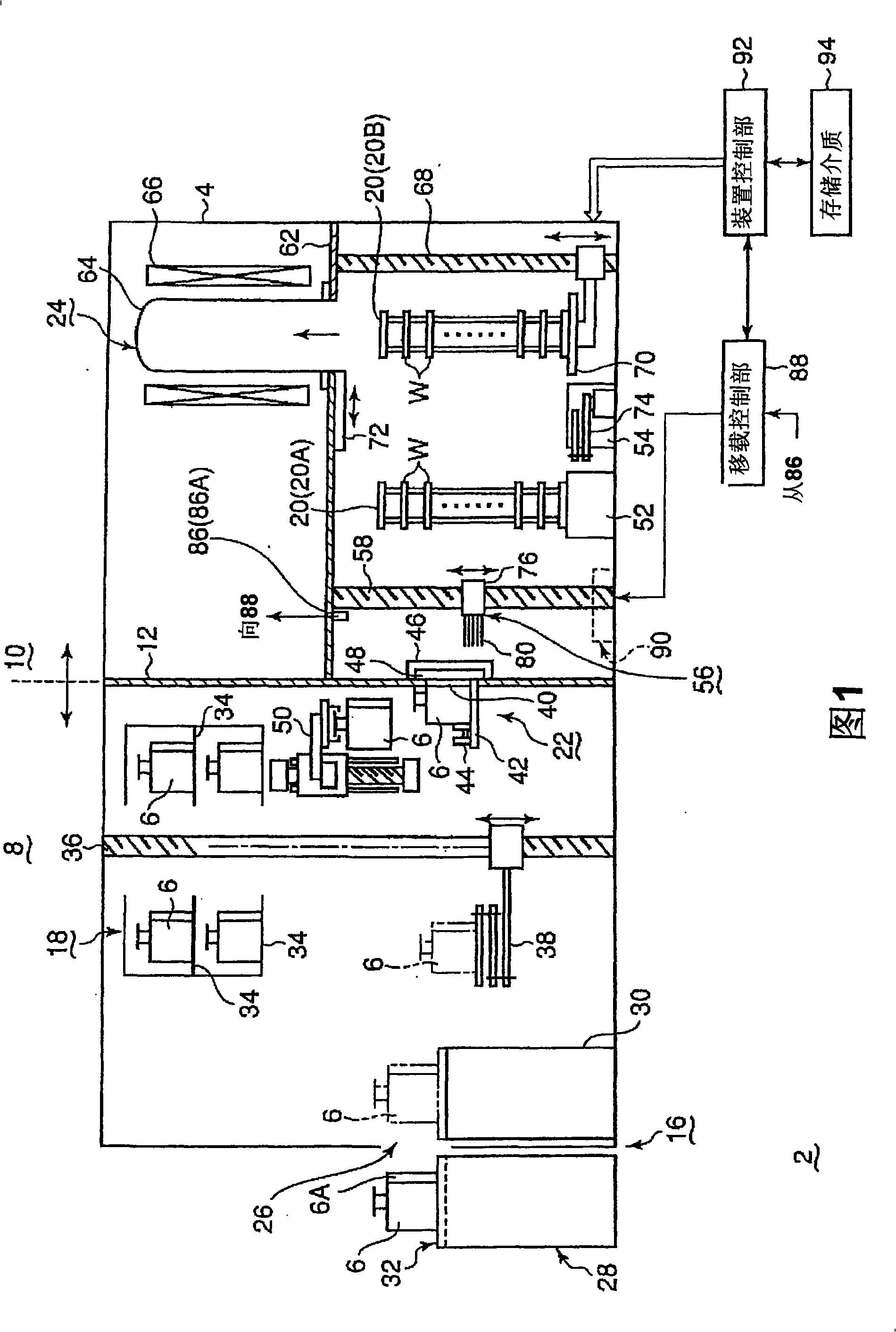

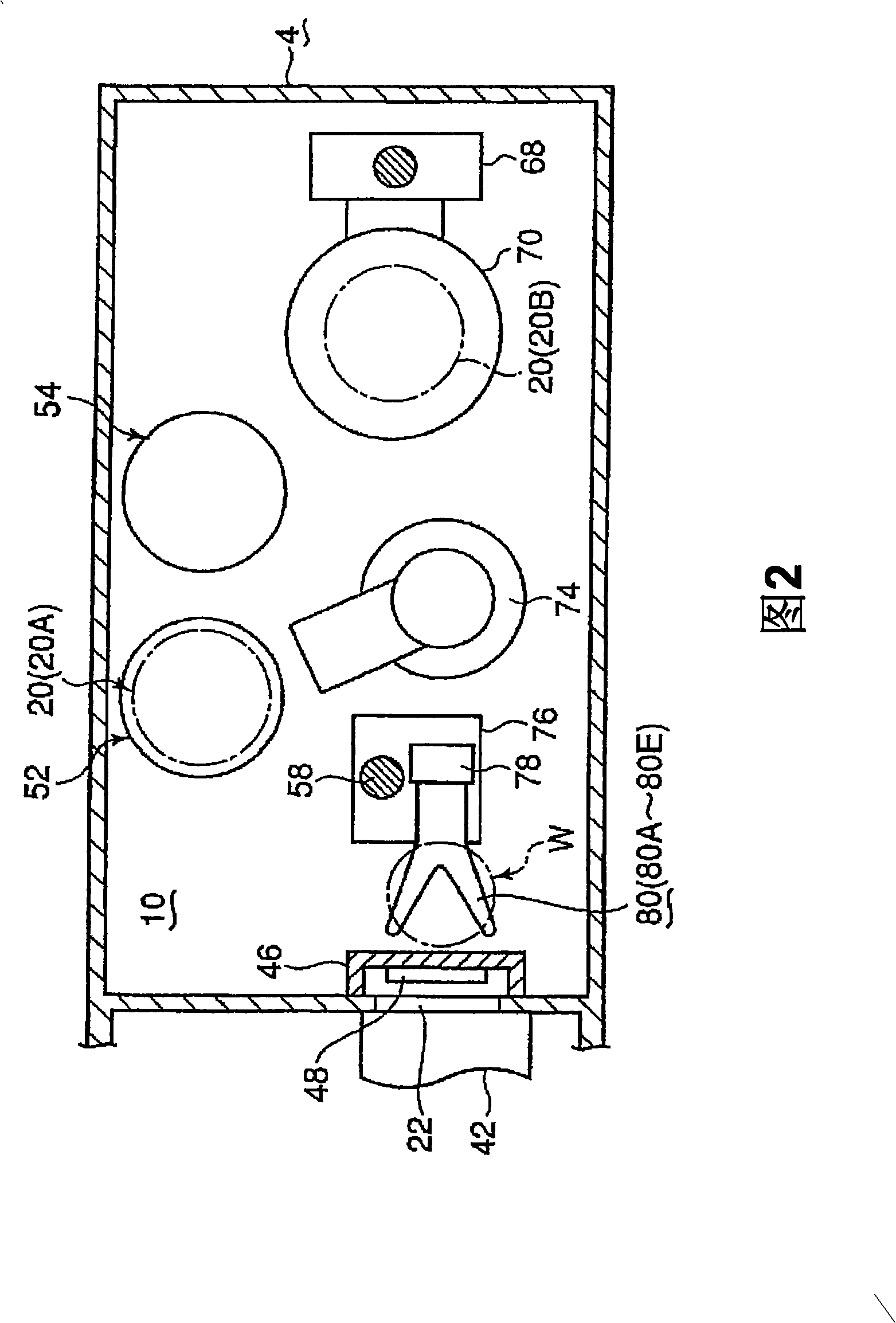

[0044] Fig. 1 is a schematic configuration diagram showing an example of the processing system of the object to be processed according to the present invention, Fig. 2 is a plan view showing an example of the arrangement position of each constituent member in the object transfer region, and Fig. 3 is a schematic diagram showing A diagram of an example of a transfer arm mechanism for an object to be processed.

[0045] First, as shown in FIG. 1 and FIG. 2, the processing system 2 of the object to be processed is surrounded by a frame body 4, which functions as a partition wall as a whole, and is made of, for example, stainless steel, and its interior is divided into: There are two parts: a storage box transfer area 8 for transferri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com