Foreign body machine vision recognition method and device for assembly line special-shaped bottling liquid

A bottled liquid and machine vision technology, which is applied in machine vision recognition of foreign matter, automatic detection device on the filling line, and bottled liquid production field, can solve the problems of easy fatigue of inspectors, low efficiency of manual detection, poor repeatability, etc., to achieve The effect of saving human resource costs, fast detection speed and strong adaptability

Inactive Publication Date: 2009-04-08

HUNAN UNIV

View PDF0 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem solved by the present invention is to overcome the problems of low manual detection efficiency, poor repeatability, high missed detection rate, low precision, and easy fatigue of detection personnel in the existing detection of foreign matter in special-shaped bottles, and provide a special-shaped bottled liquid in the production line. Foreign body machine vision recognition method and device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

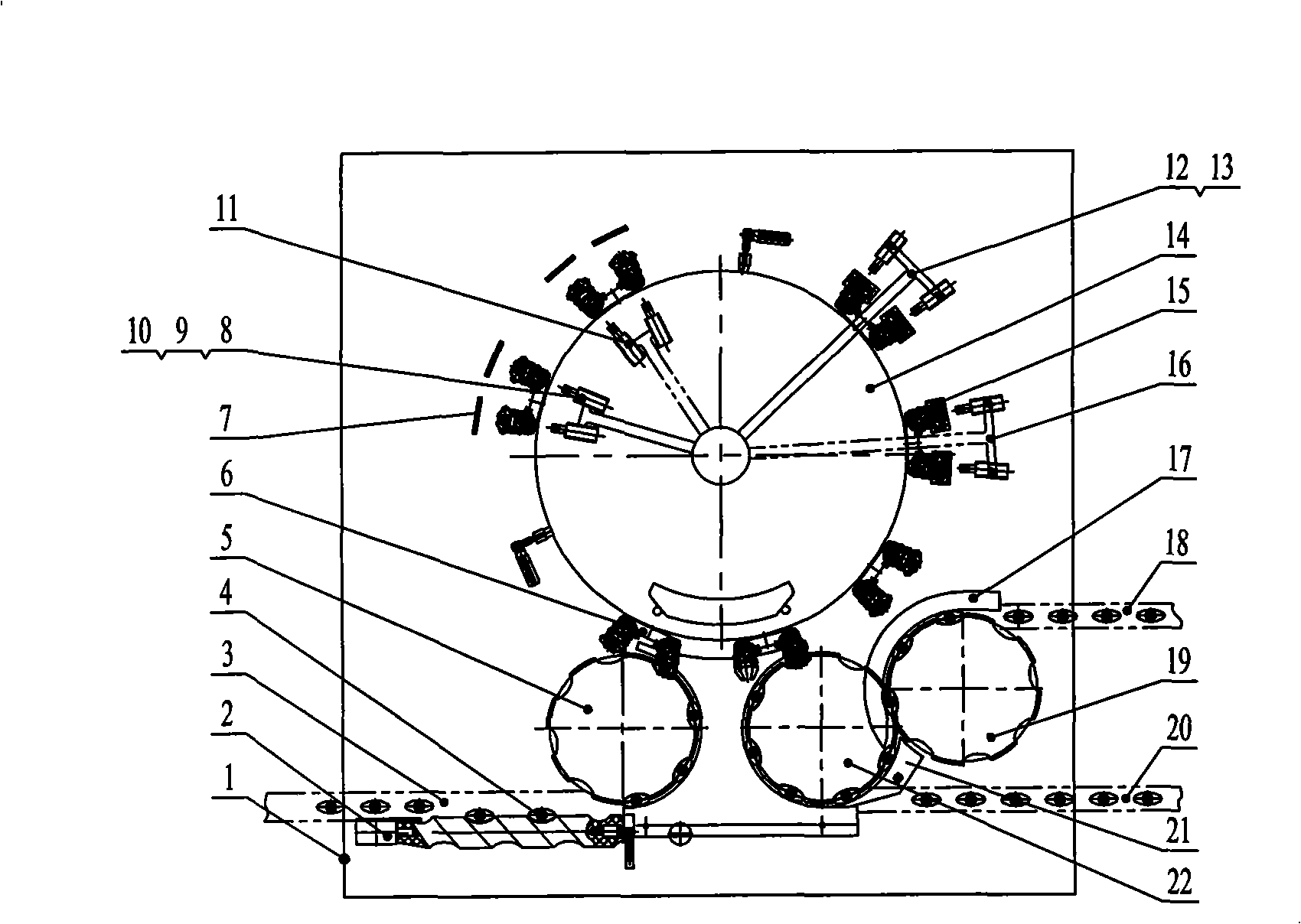

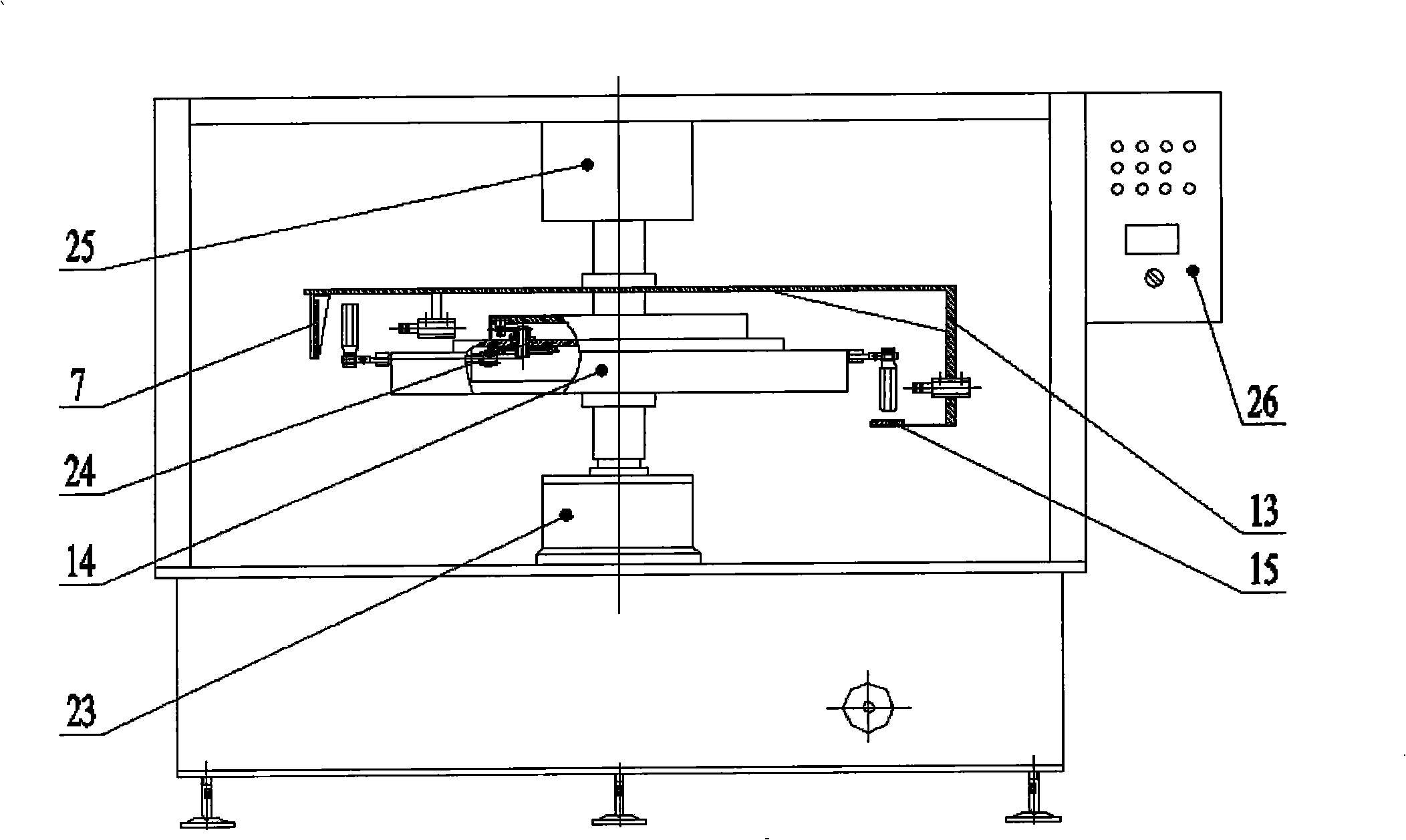

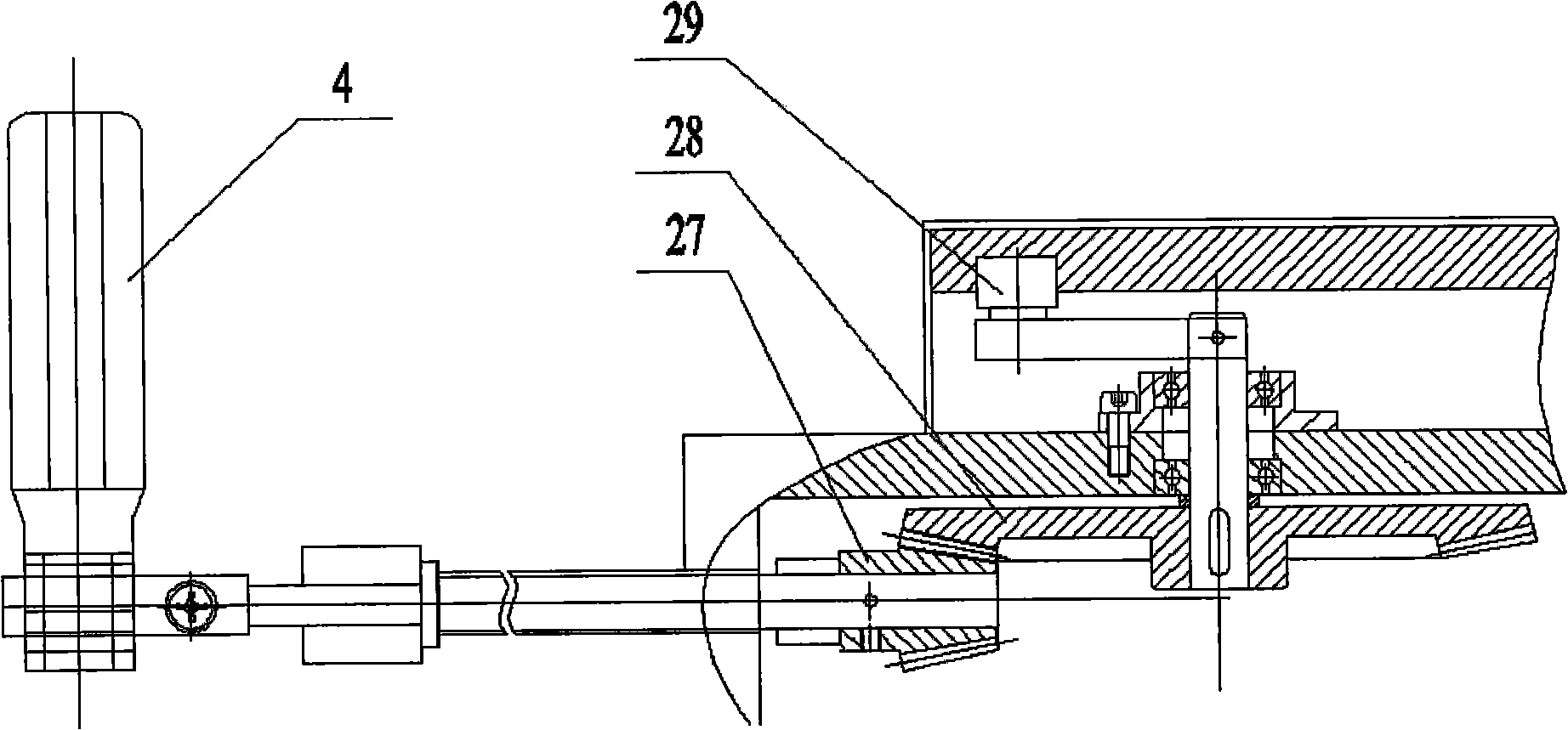

[0054] The main part of the device of the invention is located at figure 1 A closed light-isolating body 1 is shown. The mechanical transmission part mainly includes: a bottle feeding mechanism, a side turning mechanism 24, a main rotating worktable 14, a bottle discharging mechanism and so on.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a machine visible recognition method used for recognizing foreign matter in profiled bottled liquid of pipelining, comprising the steps as follows: 1. a the profiled bottle is arranged at a first detection working position and the profiled bottle is inversely arranged; and black foreign matter is detected by photographing images; 2. the profiled bottle is arranged at a second detection working position and in a normal position and the white foreign matter is detected by photographing images; 3. digital image tracking processing is carried out to the obtained multi-frame serial images so as to obtain the result used for judging whether the profiled bottle is qualified or not; and 4. according to the judgment result, the unqualified bottles are removed out of the detection pipelining. The invention also discloses a machine visible recognition device used for recognizing the foreign matter in the profiled bottled liquid of pipelining. The device and the method can achieve the automatic and quick detection of the foreign matter in the liquid of the profiled bottle of the pipelining.

Description

Technical field [0001] The invention belongs to the field of industrial machine vision detection, and relates to an automatic detection device on a bottled liquid production and filling line, in particular to a machine vision recognition method and device for foreign matter in a special-shaped bottled liquid on a production line. Background technique [0002] my country is a major producer and consumer of bottled products such as alcohol, medicine, and beverages. In recent years, with the continuous improvement of consumption levels, the current US Good Manufacturing Practices (cGMP) and the promotion of the US Food and Drug Administration FDA standards have made it inevitable to operate strictly in accordance with production standards in such industries. FDA pays more attention to traceability and accountability, and interprets the concepts of reliability and accuracy. At present, domestic manufacturers do not have a good understanding of this concept in terms of PLC software, r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N21/90

Inventor 王耀南葛继周博文张辉朱惠峰秦虹肖方良章倢曹麟

Owner HUNAN UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com