Locking device for electric motor shaft connection of robot joint

A technology of robot joints and locking devices, which is applied in the direction of joints, manipulators, couplings, etc., can solve the problems of inconvenient installation and disassembly, small transmission torque, small transmission force and torque, etc., to achieve convenient installation and disassembly, Guaranteed installation accuracy and large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

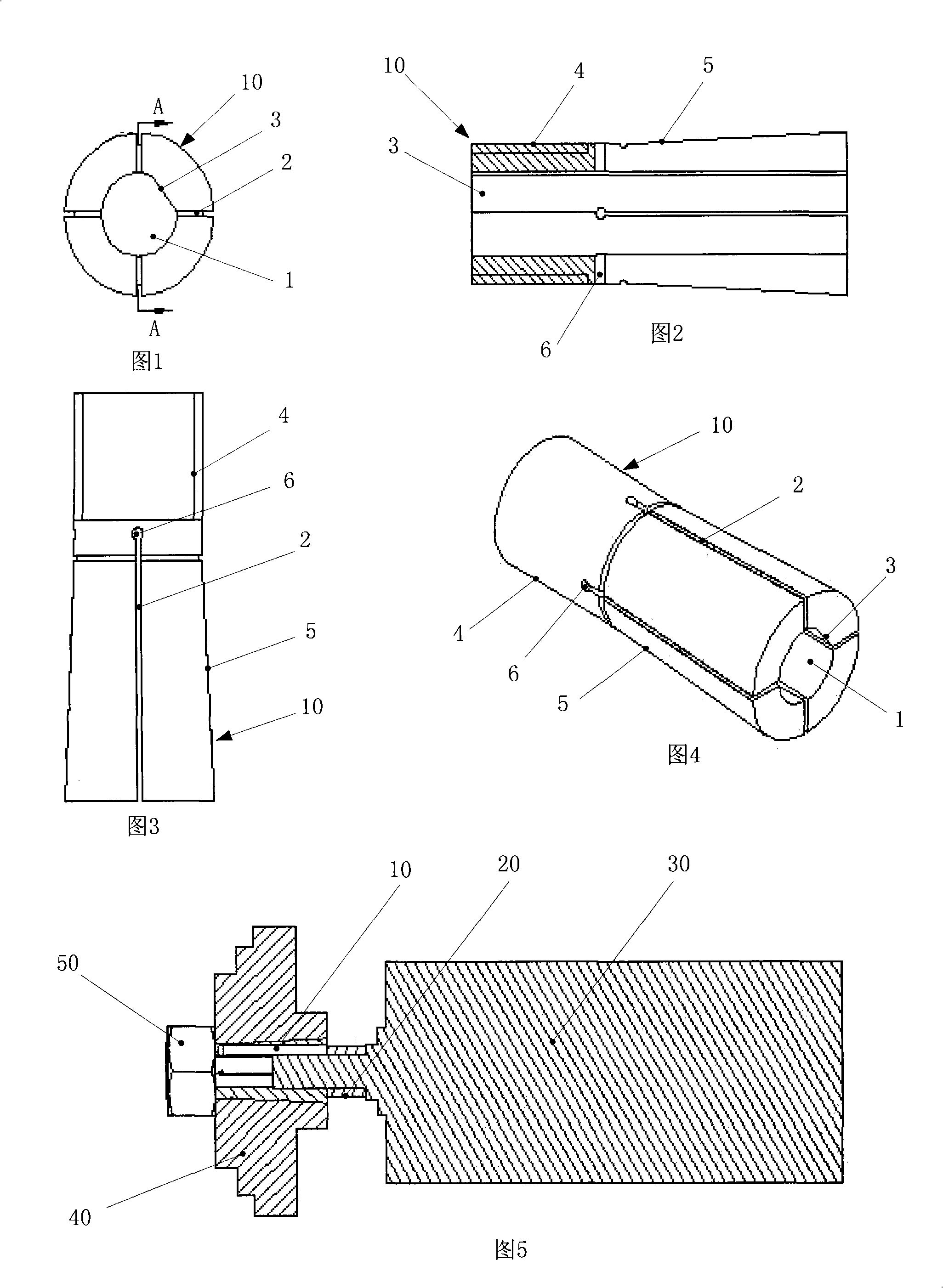

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0023] As shown in Fig. 1-5, a locking device 10 used for connecting the motor shaft of the robot joint is sleeved on the outside of the motor shaft to realize the fixation of the motor shaft and the transmission of torsion. The locking device 10 includes a cylindrical main body, which is provided with an inner hole 1 matching the motor shaft. The inner hole 1 is a flat section 3 along the circumference of the hole wall, and the flat section 3 is used to prevent The motor shaft is loose and slipping. The outside of the main body is sequentially provided with a cone section 5 with a large upper part and a small bottom section and a threaded section 4 . The taper of the cone segment 5 is 1:10-1:20, and the optimum taper is 1:16. The outer wall of the main body is provided with a slot 2 parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com